Preparation method of composite bipolar plate for all-vanadium redox flow battery

An all-vanadium redox flow battery, bipolar plate technology, applied in fuel cell parts, fuel cells, regenerative fuel cells, etc., can solve the problems of reduced battery performance, poor reversibility, easy to etch, etc., to reduce the resistivity. , Low processing cost, the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A composite bipolar plate for an all-vanadium redox flow battery, prepared by the following method:

[0032] (1) The polyethylene modified plastic and 1mm foamed nickel are configured according to a certain weight ratio of 70%: 30%, and the polyethylene modified plastic is made into a 2mm flat plate, which is placed between the upper and lower layers of foamed nickel;

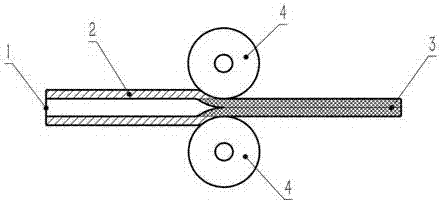

[0033] (2) Pass the polyethylene modified plastic plate sandwiched between the two layers of nickel foam obtained in step (1) through the double rollers heated to 130°C at a speed of 3m / h to obtain a composite conductive plastic plate;

[0034] (3) Put the 3mm graphite felt for vanadium battery in 70% concentrated sulfuric acid for 8 hours, wash it with deionized water, put it in a muffle furnace, bake it at 180°C for 6 hours, and take it out for use ;

[0035] (4) Place the polyethylene-modified plastic composite board in a custom-made fixture, then place two pieces of 3mm graphite felt and polyethylen...

Embodiment 2

[0037] A composite bipolar plate for an all-vanadium redox flow battery, prepared by the following method:

[0038] (1) Configure the polycarbonate modified plastic and 1mm graphite felt according to a certain weight ratio of 80%: 20%, and make the polycarbonate modified plastic into a 2mm flat plate, and place it between the upper and lower layers of graphite felt between;

[0039] (2) Pass the polycarbonate modified plastic plate sandwiched between the two layers of graphite felt obtained in step (1) through double rollers heated to 150°C at a speed of 5m / h to obtain a composite conductive plastic plate;

[0040] (3) Treat 8mm graphite felt for vanadium batteries in 98% concentrated sulfuric acid for 4 hours, wash it with deionized water, put it in a muffle furnace, bake it at 240°C for 5 hours, and take it out for use ;

[0041] (4) Place the polycarbonate modified plastic composite board in a custom-made fixture, then place two pieces of 8mm graphite felt and polycarbona...

Embodiment 3

[0043] A composite bipolar plate for an all-vanadium redox flow battery, prepared by the following method:

[0044] (1) The polyaniline modified plastic and 1mm carbon fiber paper are configured according to a certain weight ratio of 90%:10%, and the polyaniline modified plastic is made into a 2mm flat plate, which is placed between the upper and lower layers of carbon fiber paper;

[0045] (2) Pass the polyaniline modified plastic plate sandwiched between the two layers of carbon fiber paper obtained in step (1) through double rollers heated to 180°C at a speed of 10m / h to obtain a composite conductive plastic plate;

[0046] (3) Put a 6mm graphite felt for vanadium battery in 80% concentrated sulfuric acid for 6 hours, wash it with deionized water, put it in a muffle furnace, bake it at 300°C for 4 hours, and take it out for use ;

[0047] (4) Place the polyaniline-modified plastic composite board in a custom-made fixture, then place two pieces of 6mm graphite felt and poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| voltage efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com