Anti-reflection method for beam sampling grating in intense laser system

A technology of sampling gratings and strong lasers, applied in the direction of diffraction gratings, optics, optical components, etc., can solve the problems of laser damage threshold decrease in transmittance, film pollution, transmittance and damage threshold decrease, etc., to achieve performance and stability Sexual problems, stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

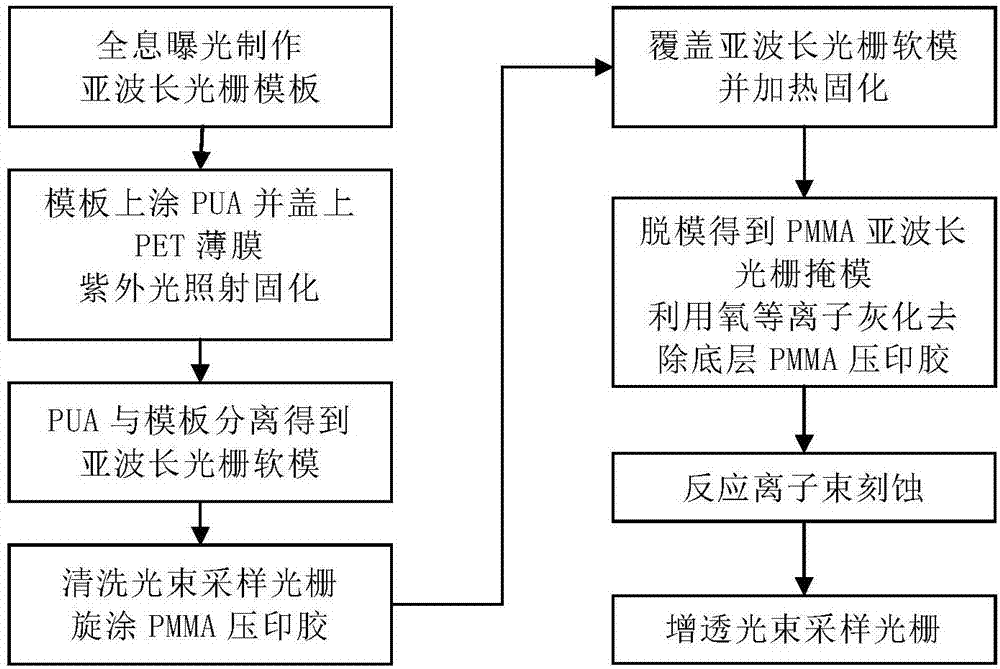

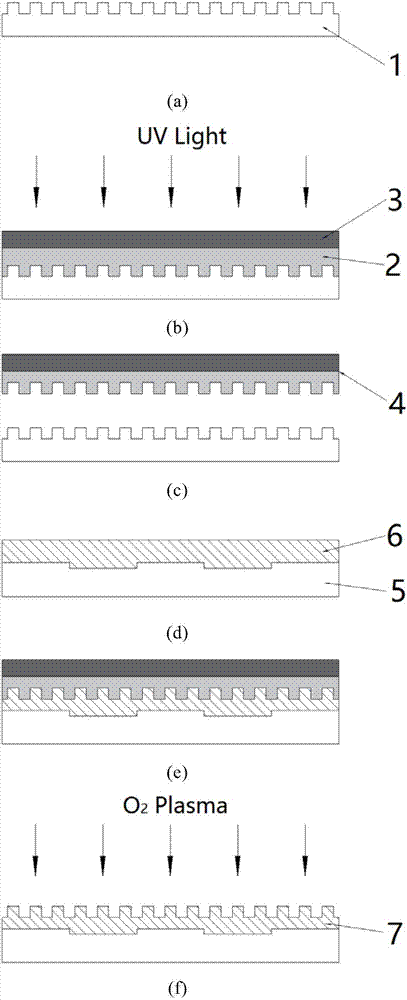

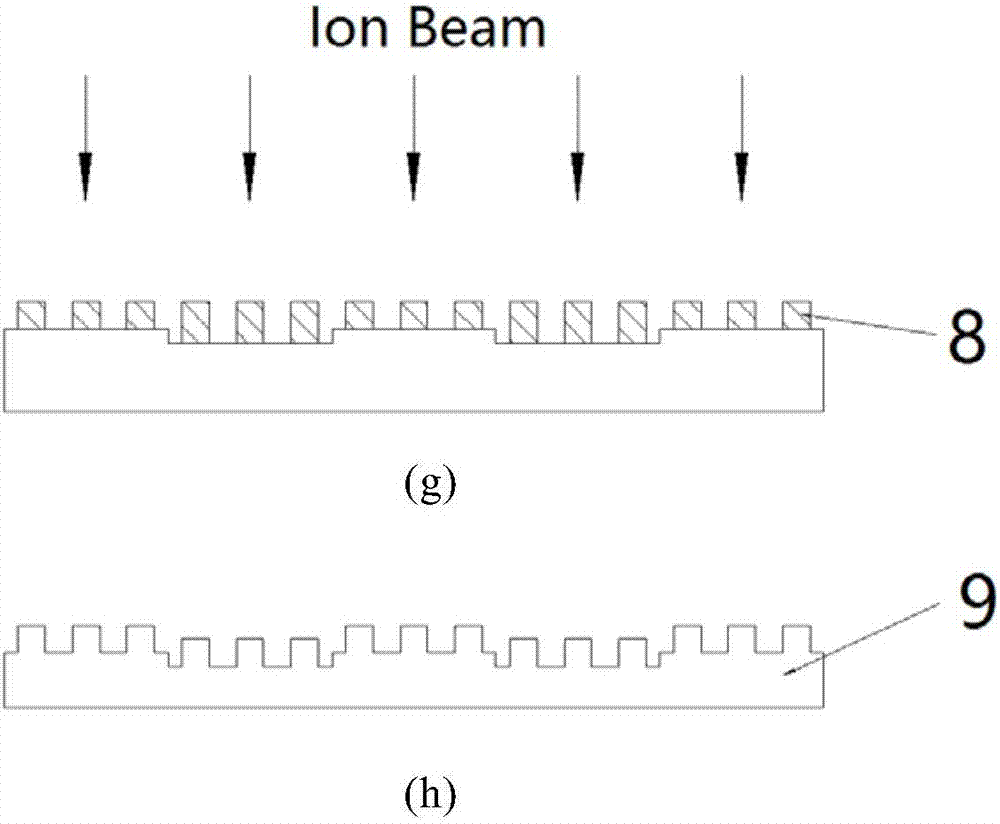

[0036] Embodiment 1: this specific implementation mode is to make size be 100 * 100mm 2 The anti-reflection beam sampling grating. Including the following specific steps, such as figure 1 Shown:

[0037] (1) In size 100×100mm 2 A photoresist was spin-coated on a fused silica substrate with a thickness of 200 nm. Then using Kr with a wavelength of 413.1nm + Ion laser is used for holographic exposure to obtain a sub-wavelength grating photoresist mask with a line density of 4500lines / mm and a duty ratio of 0.3 to 0.5, and then use CHF 3 Reactive ion beam etching with a depth of 150nm, and finally cleaning to remove residual photoresist to obtain a subwavelength grating template 1, such as figure 2 In (a) shown.

[0038] (2) After cleaning the sub-wavelength grating template 1, drop polyurethane acrylate (PUA) UV imprinting glue 2 on it, and then let it stand for PUA to fill the template. fill template. Then cover the polyethylene terephthalate (PET) film 3 on the PUA, a...

Embodiment 2

[0045] Embodiment 2: this specific implementation mode is to make size be 430 * 430mm 2 The anti-reflection beam sampling grating adopts the method of splicing small gratings to realize a large-size anti-reflection grating.

[0046] (1) First make a size of 100×100mm 2 The sub-wavelength grating soft mold 4, this step is the same as the steps (1)-(3) in the embodiment 1, see the splicing method image 3 , using a 4×4 grid, so a total of 16 sub-wavelength grating soft molds need to be repeatedly produced.

[0047] (2) The size is 430×430mm 2 Spin-coat the PMMA embossing glue with a thickness of 250nm on the beam sampling grating 10, and then press image 3 In the splicing method shown, 16 sub-wavelength grating soft molds are embossed, and after heating and curing, the mold is released to obtain a large-size PMMA sub-wavelength grating mask.

[0048] (3) Use the oxygen plasma ashing method to remove the residual PMMA imprinting glue at the bottom. Due to the large size of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com