Composite lithium metal negative electrode based on MXene aerogel and synthesis method thereof

A metal negative electrode and a synthesis method technology, which can be used in negative electrodes, electrode manufacturing, electrical components, etc., can solve the problems of low coulombic efficiency of lithium dendrites, and achieve the effects of avoiding lithium dendrites, suppressing stacking, and suppressing volume expansion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1) Disperse MXene in water at normal temperature and pressure to prepare 10 mL of 5 mg mL -1 the dispersion liquid;

[0033] 2) Dissolve polyvinyl alcohol in water at 90°C to prepare 10mL of 5mg mL -1 polyvinyl alcohol solution;

[0034] 3) Slowly add the polyvinyl alcohol solution prepared in step 2) dropwise to the MXene dispersion prepared in step 1) under normal temperature and pressure conditions, and mix evenly; the mass fraction of MXene in the mixed solution is 50%.

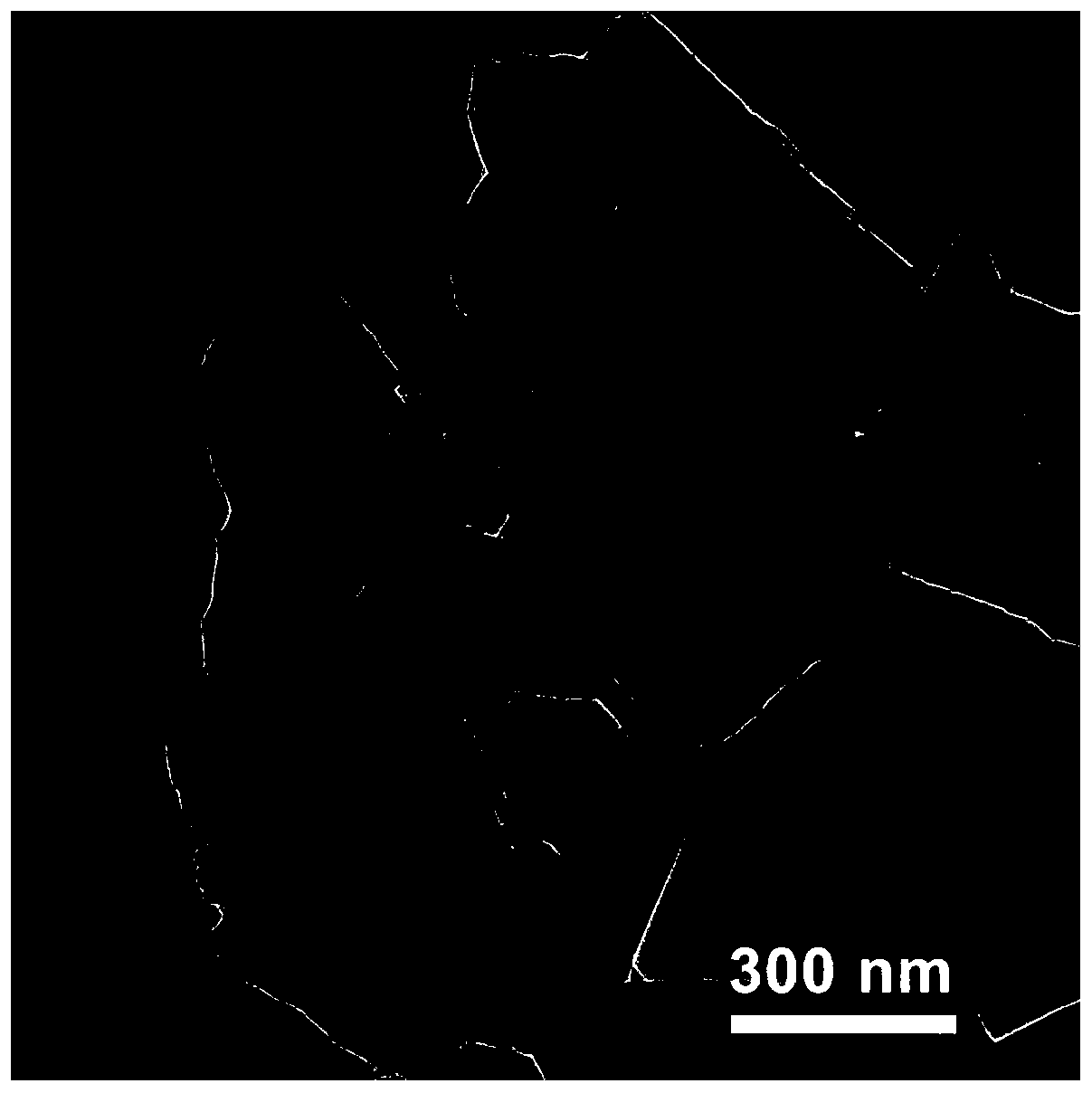

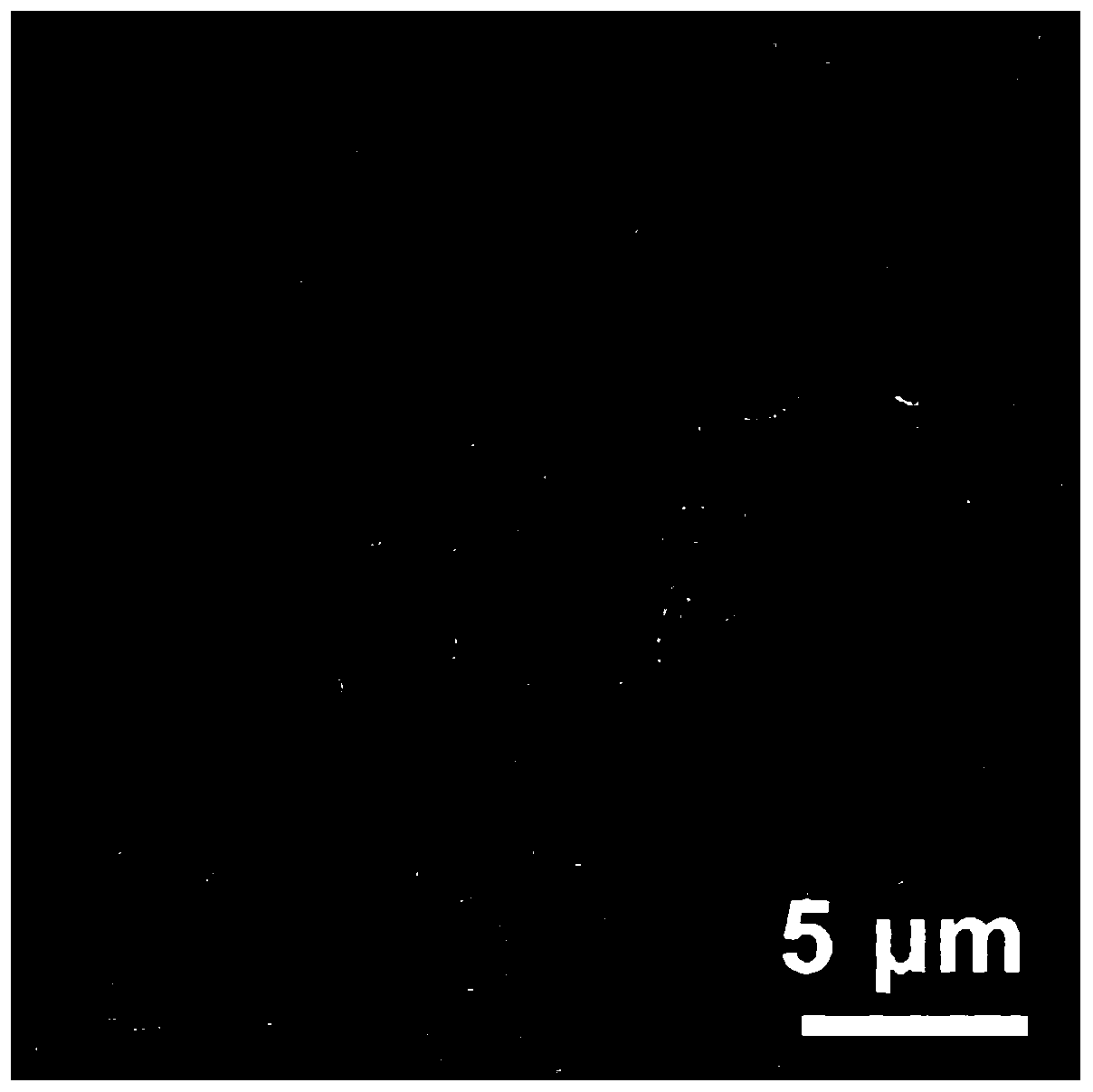

[0035] 4) Put the mixed solution prepared in step 3) in an ultrasonic cleaning machine for ultrasonic treatment for 1 hour to make it completely gelled, and then freeze-dry it for 48 hours to obtain a three-dimensional MXene airgel; the obtained three-dimensional MXene The pore size distribution of the airgel is between 2-50 μm, and the diameter of the three-dimensional MXene airgel is 14 mm, and the thickness is 300 μm.

[0036] 5) Assemble a 2016 button cell in a glove box filled with argon, t...

Embodiment 2

[0039] 1) Disperse MXene in water at normal temperature and pressure to prepare 7mL with a concentration of 8mg mL -1 the dispersion liquid;

[0040] 2) Dissolve polyvinyl alcohol in water at 95°C to prepare 3 mL of 8 mg mL -1 polyvinyl alcohol solution;

[0041] 3) Slowly add the polyvinyl alcohol solution prepared in step 2) dropwise to the MXene dispersion prepared in step 1) under normal temperature and pressure conditions, and mix evenly; the mass fraction of MXene in the mixed solution is 70%.

[0042] 4) Place the mixed solution prepared in step 3) in an ultrasonic cleaner for ultrasonic treatment for 2 hours to make it completely gelled, and then freeze-dry it for 60 hours to obtain a three-dimensional MXene airgel; the obtained three-dimensional MXene airgel The pore size distribution of the gel is between 50-80 μm, and the three-dimensional MXene airgel has a diameter of 16 mm and a thickness of 500 μm.

[0043] 5) Assemble a 2016 button cell in a glove box filled...

Embodiment 3

[0046] 1) Disperse MXene in water at normal temperature and pressure to prepare 9 mL of 10 mg mL -1 the dispersion liquid;

[0047] 2) Dissolve polyvinyl alcohol in water at 100°C to prepare 1 mL of 10 mg mL -1 polyvinyl alcohol solution;

[0048] 3) Slowly add the polyvinyl alcohol solution prepared in step 2) dropwise to the MXene dispersion prepared in step 1) under normal temperature and pressure conditions, and mix evenly; the mass fraction of MXene in the mixed solution is 90%.

[0049] 4) Place the mixed solution prepared in step 3) in an ultrasonic cleaning machine for ultrasonic treatment for 3 hours to make it completely gelled, and then freeze-dry it for 72 hours to obtain a three-dimensional MXene airgel; the three-dimensional MXene airgel The pore size distribution of the gel is between 80-100 μm, and the diameter of the three-dimensional MXene airgel is 18 mm, and the thickness is 800 μm.

[0050] 5) Assemble a 2016 button cell in a glove box filled with argon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com