Conical spring type high efficiency energy-saving furnace and using method thereof

A high-efficiency energy-saving, tower spring technology, applied in wellhead heating and crude oil transportation in the petroleum industry, can solve the problems of poor heating effect, slow heating, large heat loss, etc., to achieve improved heating efficiency, small furnace volume, The effect of reducing clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

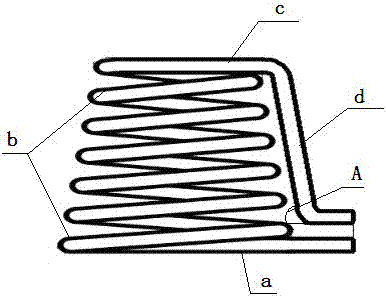

[0015] The present invention includes a chimney 1, a suspension ring 2, a shell 3, a flange 4, a furnace shell 5, an annular bracket 6, a fire starter 7, a gas furnace 8, a ventilation plate 9, and a damper 10. The top of the furnace shell 5 passes through the flange 4 The shell 3 is connected with bolts, the top of the shell 3 communicates with the chimney 1 in the middle, the upper end surface of the shell 3 is symmetrically provided with two lifting rings 2, and the inside of the furnace shell 5 is provided with a ring-shaped bracket 6, The tower spring heating coil 11 is fixed on the annular support 6, and the bottom of the annular support 6 is provided with an ignition device 7 and a gas furnace 8. The ignition device 7 is located at the top of the gas furnace 8, and the inlet of the tower spring heating coil 11 And the outlet extends to the outside of the furnace shell 5, the gas furnace 8 is fixed on the ventilation plate 9 inside the furnace shell 5, the ventilation pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com