Clamping jaw grabbing mechanism for box filler

A technology of grabbing mechanism and packing machine, which is applied in the field of gripping jaw grabbing mechanism, can solve the problems of affecting work efficiency, loss of packing, large manpower and material resources, etc., and achieves the effect of small gas consumption and increased stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

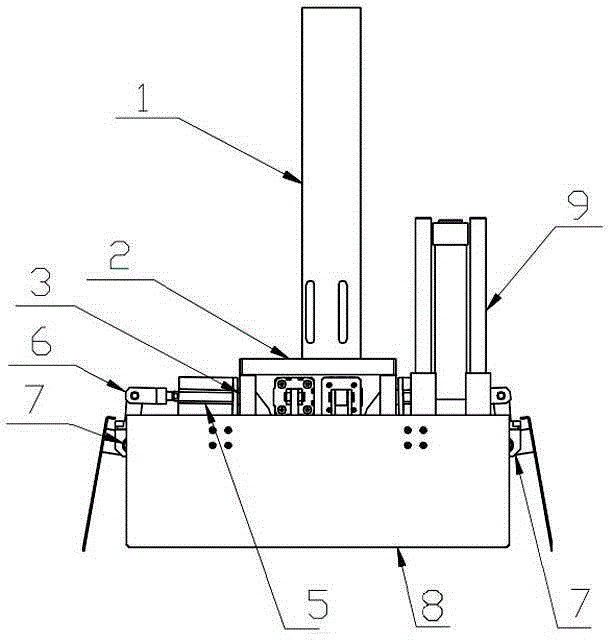

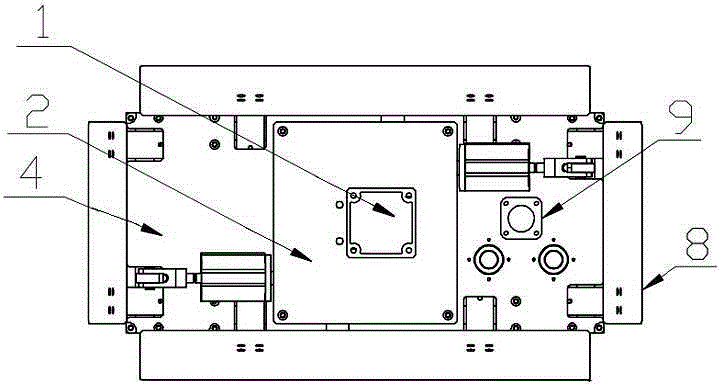

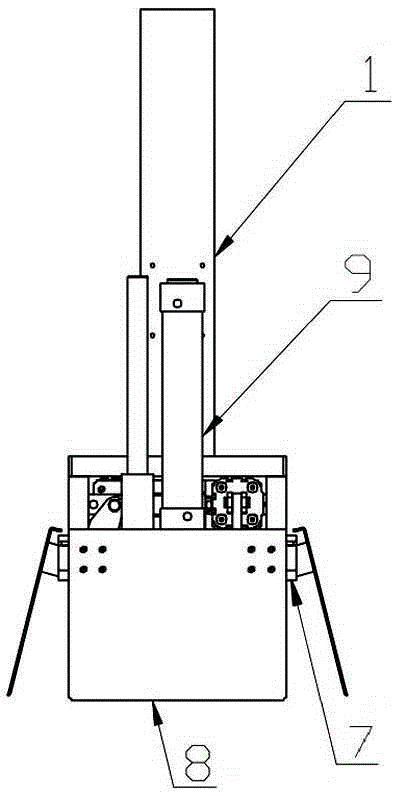

[0017] refer to Figure 1 to Figure 3 As shown, a jaw grabbing mechanism for a box packing machine includes a column 1, the bottom of which is fixed on a bottom plate 2, and the lower end of the bottom plate 2 is fixed to a cylinder through a plurality of distance rods 3 The base plate 4, the cylinder base plate 4 is provided with a plurality of horizontal grasping cylinders 5, the output shaft end of each grabbing cylinder 5 corresponds to one side of the cylinder base plate 4, and the output shaft end of the grabbing cylinder 5 is connected with A Y-shaped joint 6, the Y-shaped joint 6 is rotatably provided with a driving shaft 7, the other end of the driving shaft 7 is rotatably arranged on the side of the cylinder base plate 4, and the driving shaft 7 is fixedly connected with a grabbing stainless steel plate 8 , the grasping cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com