Energy-saving mobile coffee baking machine

A technology for roasting machines and coffee, applied in the direction of motor vehicles, workshop/display transportation, goods transportation vehicles, etc., can solve the problems of increasing fuel consumption cost, no energy saving effect, increasing use and operation, etc., to reduce gas consumption and save management costs. , the effect of less gas consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

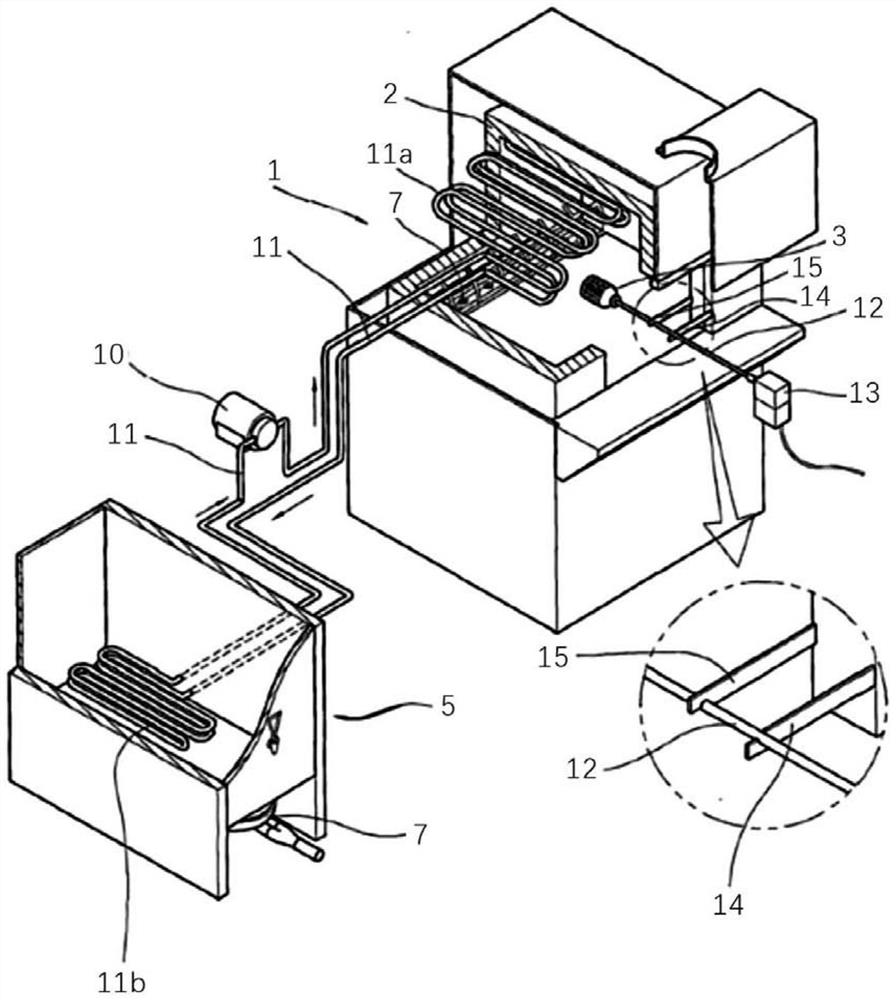

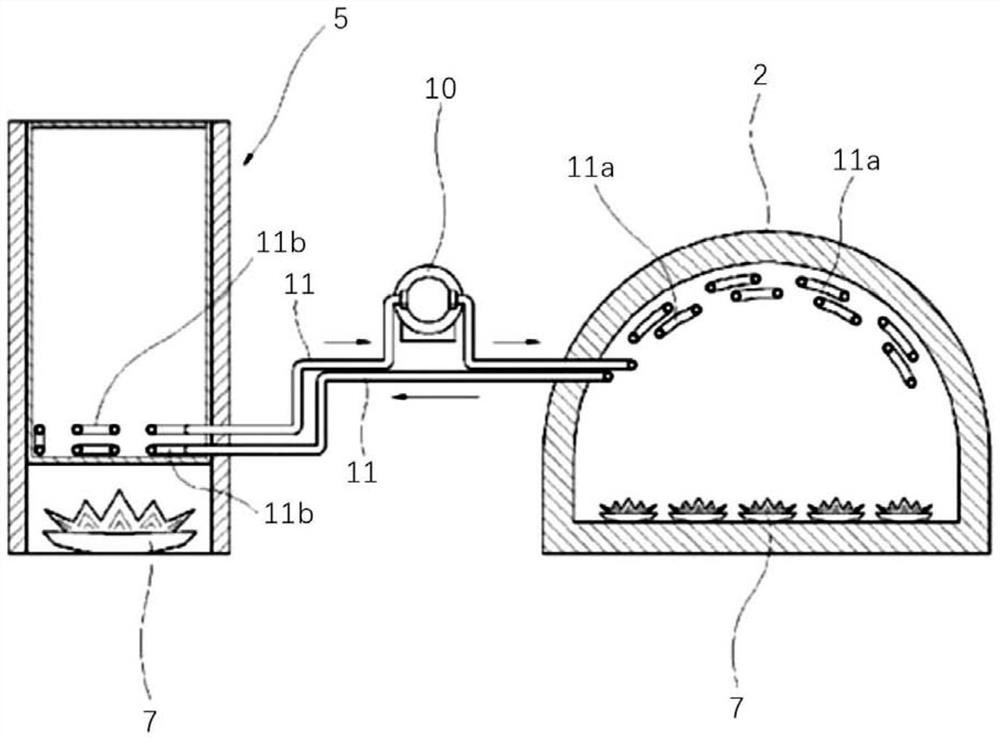

[0031] Such as Figure 1-Figure 5 As shown, an energy-saving mobile coffee roaster includes a roaster body 1, and a heating device is arranged inside the roaster body 1;

[0032] The heating device includes a radiation chamber 2, a pipeline 11 and a hot water tank 5. The bottoms of the radiation chamber 2 and the hot water tank 5 are respectively provided with a burner 7, and the two ends of the pipeline 11 extend into the radiation chamber 2 and the hot water tank respectively. 5, the pipeline 11 is provided with a transfer pump 10, and the burner 7 is a gas burner. The radiant heat generated by the heated radiation chamber 2 and the gas heat emitted by the burner 7 heat the high-temperature space, so that the baking drum 3 The coffee beans are evenly roasted;

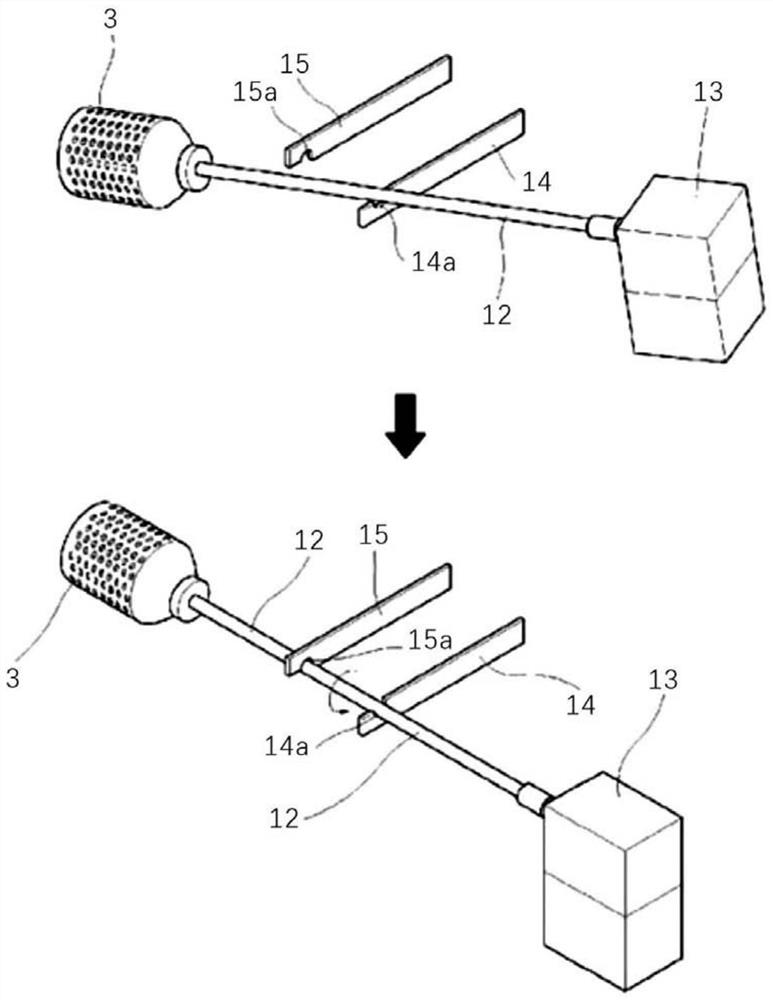

[0033] One side of the roaster body 1 is provided with a motor 13 , the output shaft of the motor 13 is provided with a rotating shaft 12 , and the end of the rotating shaft 12 away from the motor 13 penetrates into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com