Submarine mining engineering machinery

A mining engineering and machinery technology, applied in the mining of minerals, special mining, earthwork drilling, etc., can solve the problems of tailings processing trouble, inaccurate beneficiation, waste of resources, etc., to save transportation capacity, simplify processing procedures, and reduce transportation capacity waste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

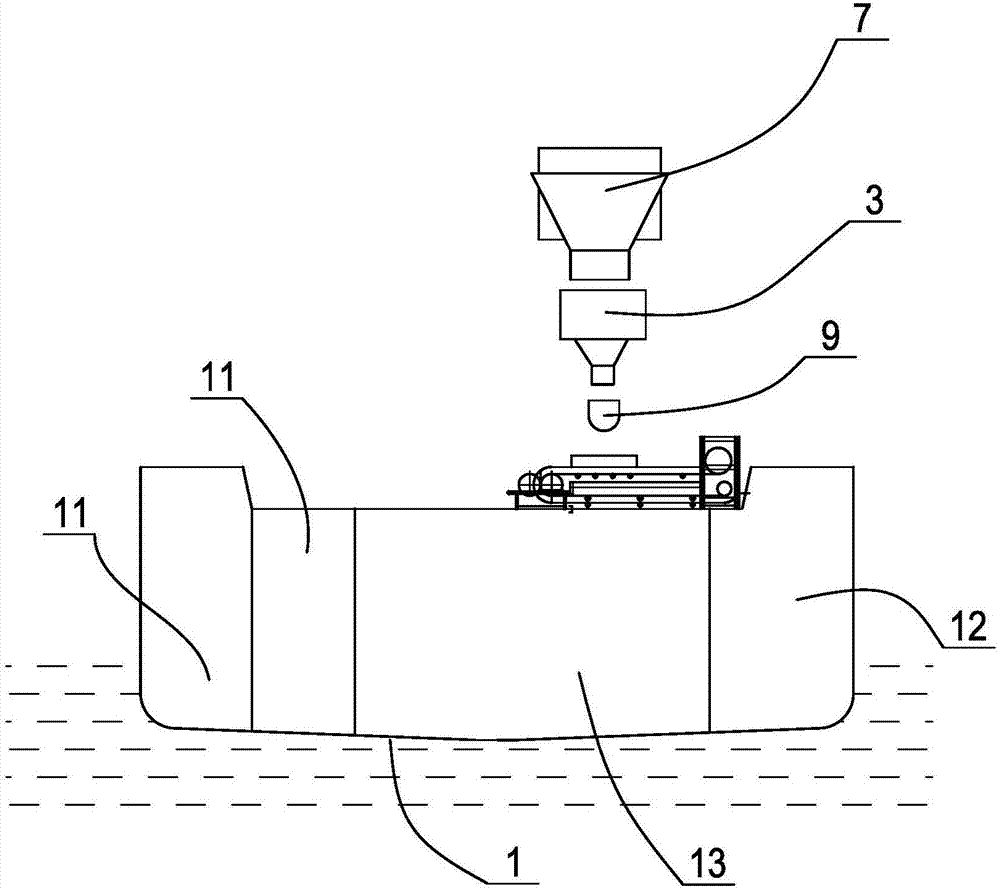

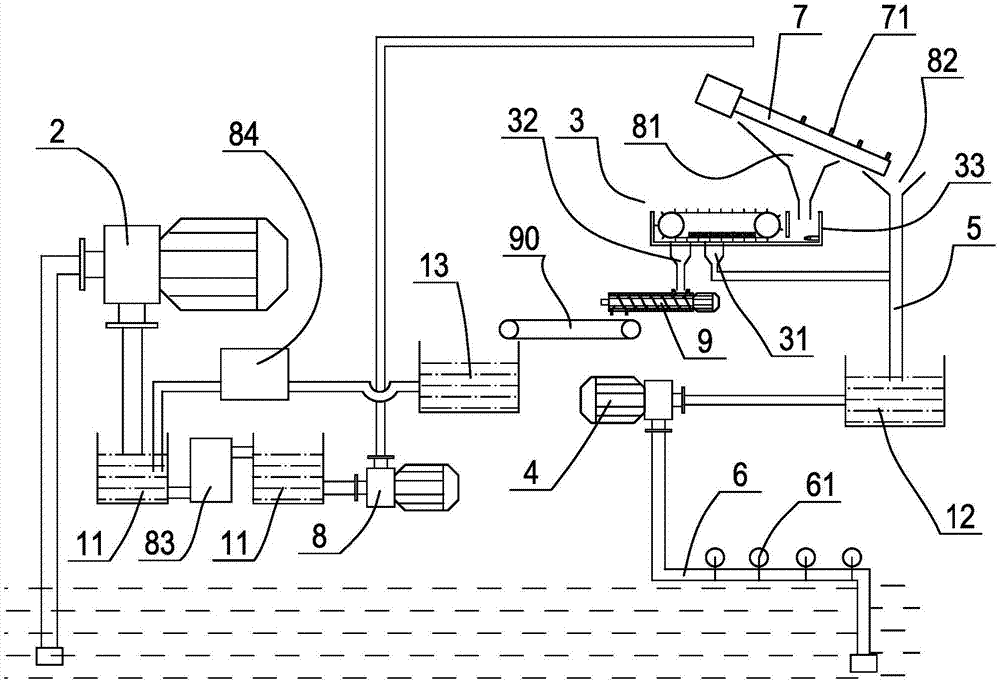

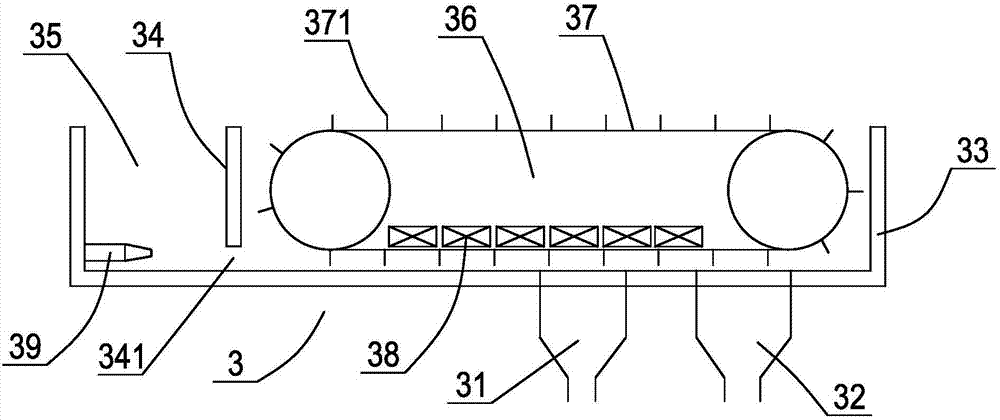

[0035] Such as figure 1 , figure 2 As shown, a marine mining engineering machinery is mainly used for collecting and beneficiating seabed raw ore sand, specifically including a self-propelled hull 1 and a sand pump 2, and two raw ore bins 11 are arranged separately in the lower part of the hull And a concentrate bin 13 and a tailings bin 12, the raw ore sand on the seabed is extracted by a high-power sand pump 2, the sand pump is powered by a diesel engine, and the sand suction port of the sand pump is connected to the seabed through a pipeline, and The sand outlet of the sand pump is connected to the first raw ore bin through a pipeline, so that the raw ore sand is extracted into the first raw ore bin. In addition, the first slurry pump 83 needs to be set between the two raw ore bins, the second slurry pump 84 is set between the concentrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com