Supporting-free mounting method of prefabricated components of prefabricated assembly type building

A prefabricated component and prefabricated assembly technology, applied in building components, building reinforcements, building structures, etc., can solve the problems of many hidden dangers, complicated erection procedures, etc., to save construction time and labor, convenient construction, and accurate component positions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0038] A support-free installation method for prefabricated building prefabricated components, characterized in that it specifically includes the following steps:

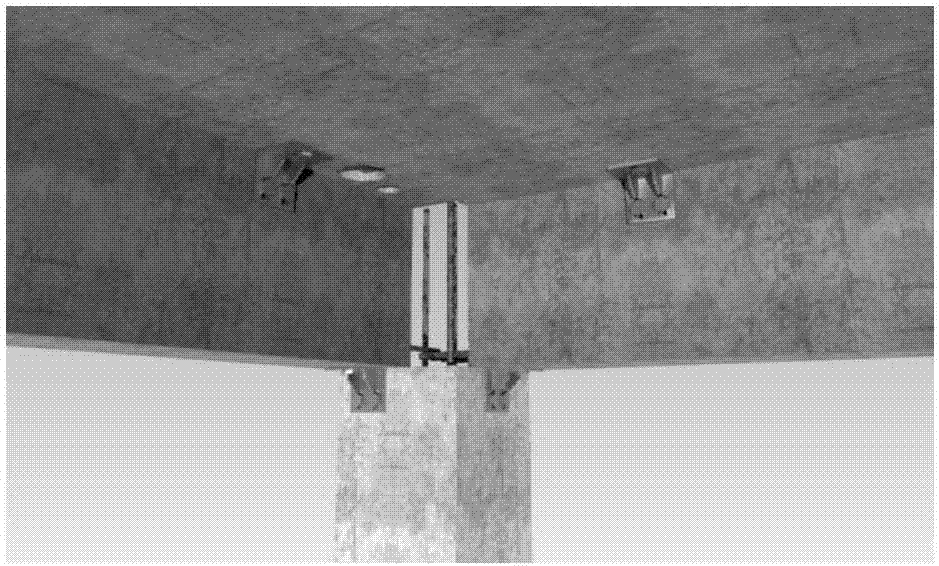

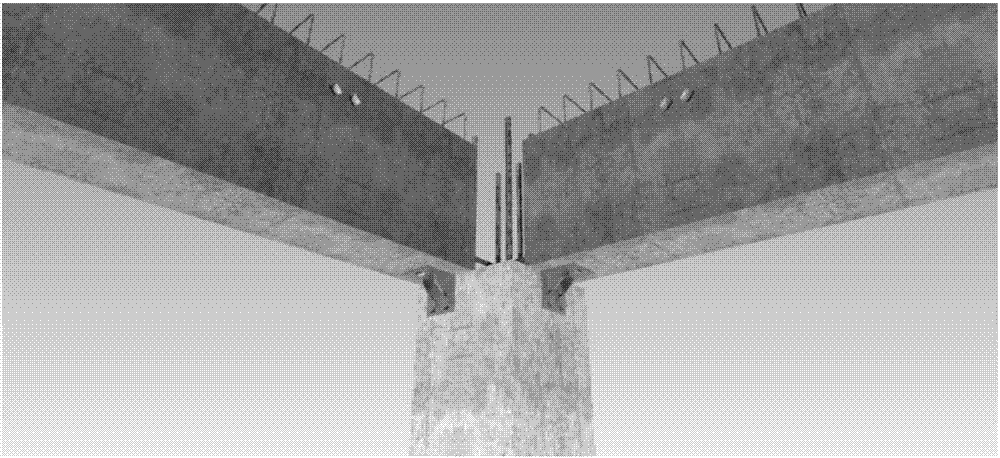

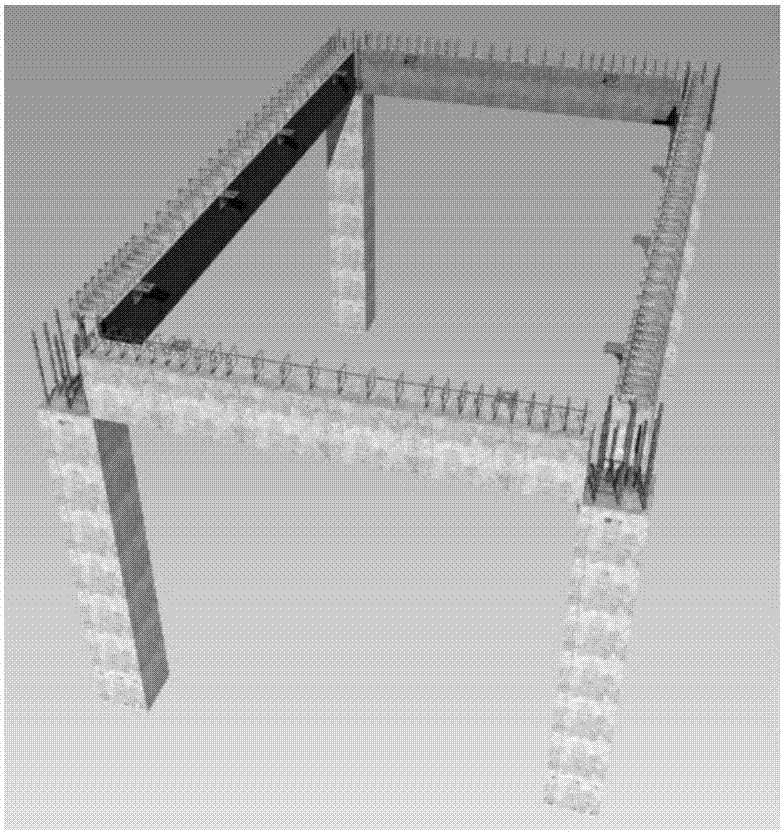

[0039](1) Detailing design of precast concrete structural beams, slabs, column members and supporting corners, modeling and deepening precast concrete members, and arranging the supporting corners and embedded connection sleeves in the components; precast concrete structural beams, slabs , column member and support angle code detail design, is based on the use of revit software to model precast concrete structural beams, slabs and column members, the position and size of support angle code are arranged, and the precast concrete structure beams, slabs and column members are arranged. The model includes steel bar model, hoisting and mold-embedding model, electromechanical embedded pipeline and hole model, and support angle code embedded connection sleeve model and support angle code model. Provide technical support f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com