Fabricated frame system adopting hot-rolling unequal-thickness U-shaped steel composite beams

A frame system, U-shaped steel technology, applied in the direction of construction, building structure, etc., to improve the ability to resist negative bending moment and ensure the effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

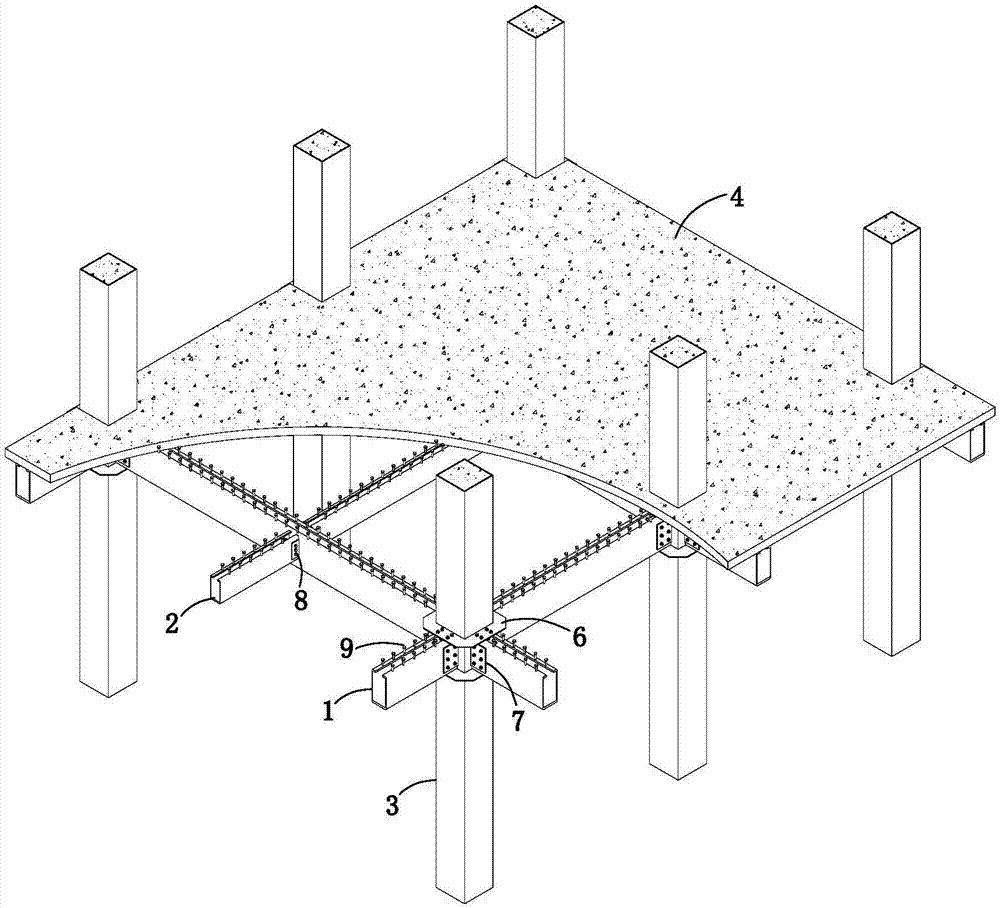

[0021] As shown in the accompanying drawings, the present invention is a prefabricated frame system using hot-rolled unequal-thickness U-shaped steel composite beams. H-shaped steel column), concrete slab, floor concrete, ring plate, ear plate, high-strength bolts, studs, and partitions, the assembly procedure is as follows:

[0022] a. Process the frame column 3 section in the factory, and weld the ring plate 5, ear plate 6 and partition plate 10 on it;

[0023] b. Process hot-rolled unequal thickness U-shaped steel main girder 1 and hot-rolled unequal thickness U-shaped steel secondary girder 2 in the factory, and reserve holes connected with ring plate 6 and lug plate 7;

[0024] c. Carry out splicing of the frame column 3 at the construction site, and connect the hot-rolled unequal thickness U-shaped steel main beam 1 to the frame column 3 with high-strength bolts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com