Perfuming method for cigarette case paper

A cigarette case and fragrance technology, which is applied in the field of cigarette case paper flavoring and cigarette case paper, can solve the problems of unpleasant smell of cigarette case paper, no fragrance of cigarette case paper, and inability to satisfy consumers, etc. Long, effective, pleasantly scented effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

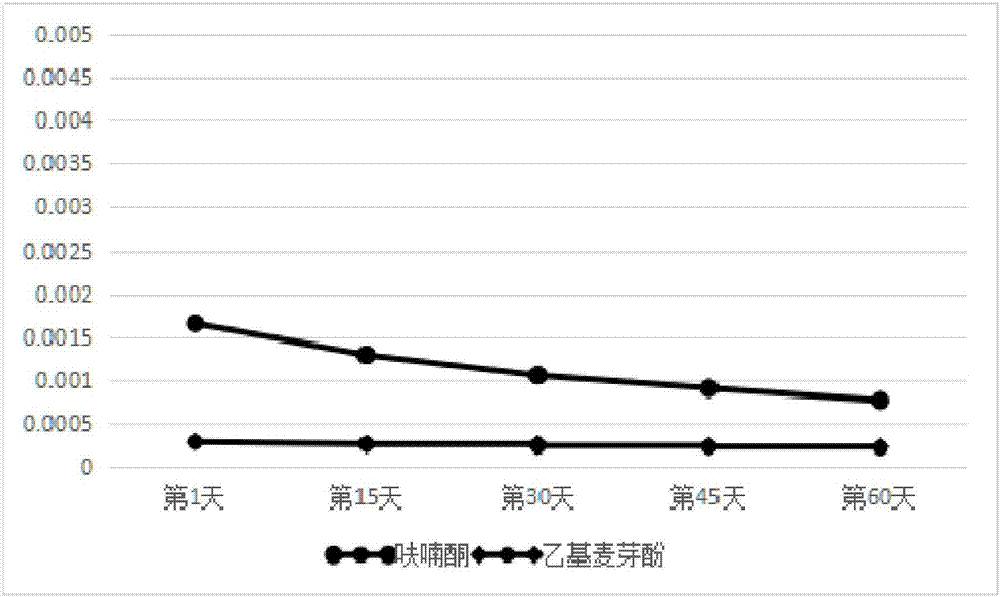

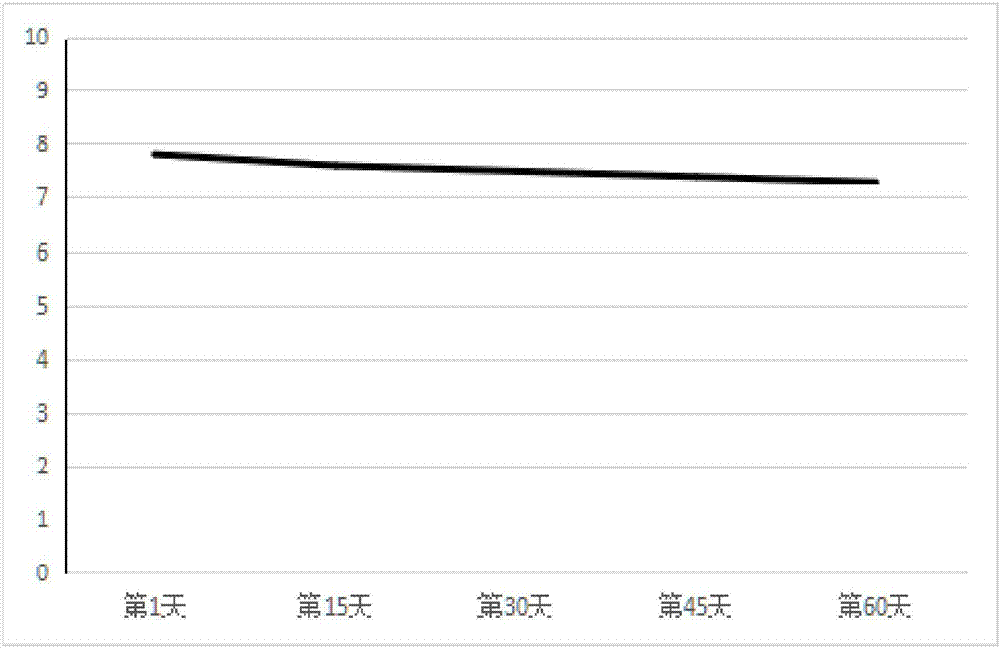

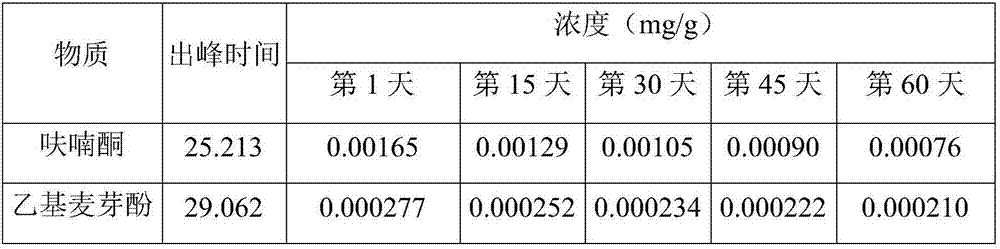

[0023] Embodiment 1, the perfuming of burnt sweet essence microcapsules on cigarette pack paper

[0024] In a 100mL beaker, mix 4.17g of burnt sweet essence (the mass ratio of furanone and ethyl maltol is 1:10) with 20.83g of hydroxypropyl-β-cyclodextrin, add 75g of absolute ethanol, Under the action of magnetic stirring at a magnetic stirring speed of 400 r / min, stir for 1.5 hours to prepare the Jiaotianxiang essence capsule solution.

[0025] Use a dropper to absorb 0.05 g of sweet-smelling fragrance capsule solution and add it to 10 g of varnish, and stir quickly with a glass rod to disperse the sweet-smelling fragrance capsules evenly in the varnish to prepare sweet-smelling varnish.

[0026] At room temperature, spread the cigarette paper on a flat plate, clamp the cigarette paper with a clip, then use a straw to absorb 1g of burnt sweet varnish and apply it on the silk stick, and then apply it evenly on the cigarette paper, apply The amount of cloth is 20g / square meter....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com