Ultrahigh pressure spray cleaning agent and preparation method and application thereof

A cleaning agent and ultra-high pressure technology, applied in the field of cleaning agents, can solve the problems of corrosion of cleaning equipment, residual dirt on metal surfaces, uncontrollable foam, etc., and achieve the effect of improving cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

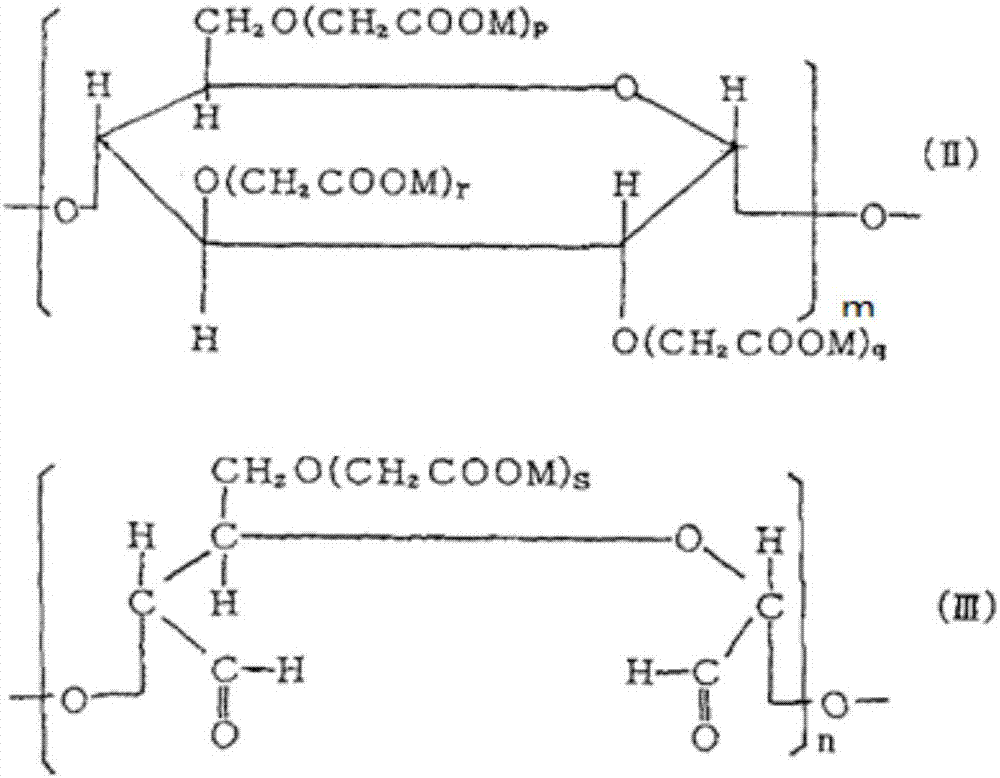

Image

Examples

Embodiment 1

[0071] An ultra-high pressure spray cleaning agent is composed of the following components by mass percentage:

[0072]

[0073]

[0074] The total number of carbon atoms in each of the 100% branched fatty alcohol polyoxyethylene ether molecules is 12, the number of branched carbon atoms is 2, and the non-blocked ethylene oxide-propylene oxide block copolymer The weight average molecular weight is 2500~2700; The non-blocked ethylene oxide-propylene oxide block copolymer is made of ethylene oxide and propylene oxide with a molar ratio of 1:1.5; the benzyl quaternary The ammonium salt is a C12 benzyl non-chloride quaternary ammonium salt.

[0075] The preparation method of described ultra-high pressure spray cleaning agent, comprises the steps:

[0076] (1) Add deionized water, monoethanolamine and triethanolamine components to the reaction kettle in sequence according to the formula, and stir at 25°C for 10 minutes to obtain the first mixed solution;

[0077] (2) Add am...

Embodiment 2

[0082] An ultra-high pressure spray cleaning agent is composed of the following components by mass percentage:

[0083]

[0084] All the other are identical with embodiment 1.

[0085] The preparation method of the ultra-high pressure spray cleaning agent is the same as that of Example 1.

Embodiment 3

[0087] An ultra-high-pressure spray cleaning agent, which consists of the following components in addition to the mass percentage:

[0088]

[0089]

[0090] All the other are identical with embodiment 1.

[0091]The ultra-high pressure spray cleaning agent is prepared by the same preparation method as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com