Method for improving clear degree of Luzhou-flavor liquor by pit mud maintenance

A technology of strong-flavor liquor and pit mud, applied in the field of winemaking, can solve the problems of optimizing the functional microbial flora of pit mud, unable to lastingly and effectively rectify the functional micro-ecological system of pit mud, etc. Acid content, the effect of promoting conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

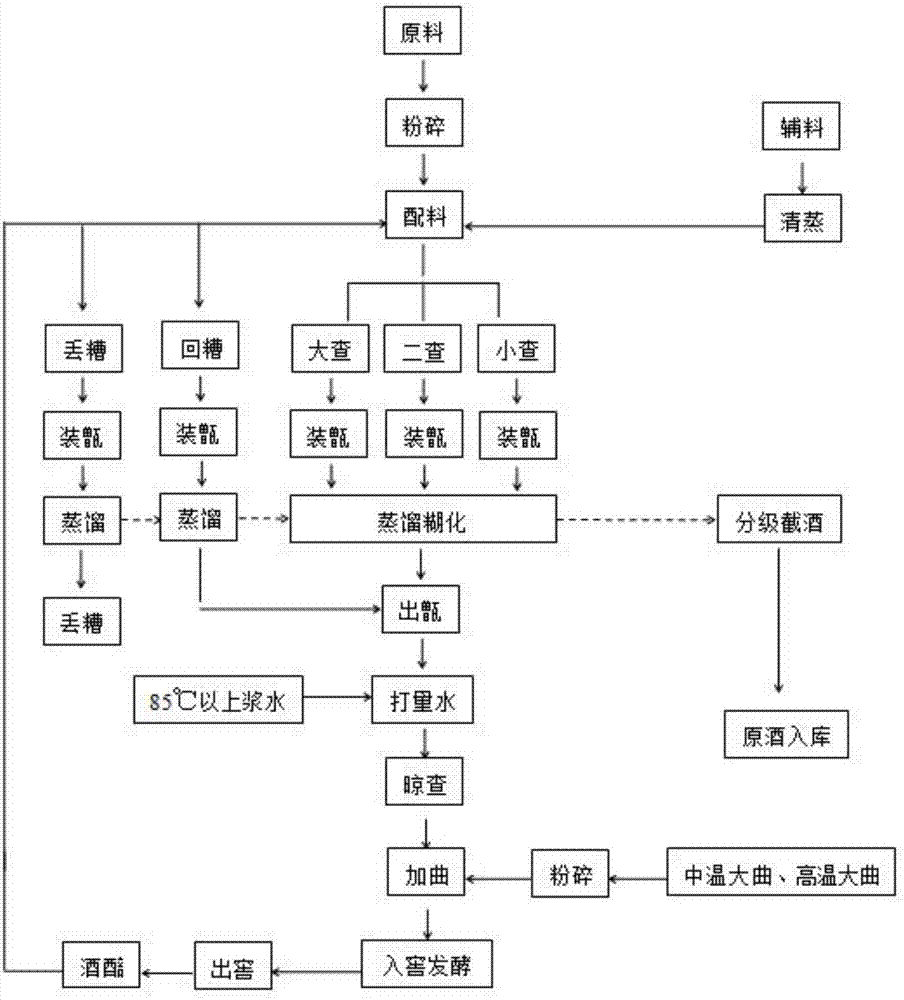

Image

Examples

Embodiment 1

[0040] High-quality pit mud functional microorganism identification medium (w / w): 1% peptone, 0.3% yeast extract, 0.5% sodium chloride, cultivated at 37°C, initial pH 7.0, liquid volume ≥ 90%. Sterilize at 115°C for 15 minutes.

[0041] Pit mud functional microbial enhancement medium (w / w): 2% ethanol, 0.5% pit mud extract, 0.5% yeast extract, 0.6% Daqu powder, culture at 37°C, initial pH 7.0, liquid volume ≥ 90%. Sterilize at 115°C for 15 minutes (ethanol is added after sterilization).

[0042] Co-culture rejuvenation medium (w / w): glucose 2%, peptone 1%, beef 0.5%, dipotassium hydrogen phosphate 0.2%. Sterilize at 115°C for 15 minutes.

[0043] Saccharomyces cerevisiae seed medium (w / w): yeast powder 1%, peptone 2%, glucose 2%, sterilized at 115°C for 15 minutes.

[0044] The liquid esterase provides Novozymes with a food-grade high-concentration lipase (product name: Esterase II) synthesized by Aspergillus niger, with an enzyme activity of 5000U / mL.

[0045] High-qualit...

Embodiment 2

[0051] High-quality pit mud functional microorganism identification medium (w / w): 1% peptone, 0.3% yeast extract, 0.5% sodium chloride, cultivated at 37°C, initial pH 7.0, liquid volume ≥ 90%. Sterilize at 115°C for 15 minutes.

[0052] Pit mud functional microbial enhancement medium (w / w): 2% ethanol, 0.5% pit mud extract, 0.5% yeast extract, 0.6% Daqu powder, culture at 37°C, initial pH 7.0, liquid volume ≥ 90%. Sterilize at 115°C for 15 minutes (ethanol is added after sterilization).

[0053] Co-culture rejuvenation medium (w / w): glucose 2%, peptone 1%, beef 0.5%, dipotassium hydrogen phosphate 0.2%. Sterilize at 115°C for 15 minutes.

[0054] Saccharomyces cerevisiae seed medium (w / w): yeast powder 1%, peptone 2%, glucose 2%, sterilized at 115°C for 15 minutes.

[0055] The liquid esterase provides Novozymes with a food-grade high-concentration lipase synthesized by Aspergillus niger, with an enzyme activity of 5000U / mL.

[0056] High-quality cellar mud should be selec...

Embodiment 3

[0061] High-quality pit mud functional microbial identification medium (w / w): 1% peptone, 0.3% yeast extract, 0.5% sodium chloride, cultivated at 37°C, initial pH 7.0, liquid volume ≥ 90%. Sterilize at 115°C for 15 minutes.

[0062] Pit mud functional microbial enhancement medium (w / w): 2% ethanol, 0.5% pit mud extract, 0.5% yeast extract, 0.6% Daqu powder, culture at 37°C, initial pH 7.0, liquid volume ≥ 90%. Sterilize at 115°C for 15 minutes (ethanol is added after sterilization).

[0063] Co-culture rejuvenation medium (w / w): glucose 2%, peptone 1%, beef 0.5%, dipotassium hydrogen phosphate 0.2%. Sterilize at 115°C for 15 minutes.

[0064] Saccharomyces cerevisiae seed medium (w / w): yeast powder 1%, peptone 2%, glucose 2%, sterilized at 115°C for 15 minutes.

[0065] The liquid esterase provides Novozymes with a food-grade highly concentrated lipase synthesized by Aspergillus niger, with an enzyme activity of 5000U / mL.

[0066] High-quality cellar mud should be selected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com