Long-acting and mildew-proof sealant composition and preparation method thereof

A sealant and composition technology, which is applied in the directions of adhesives, adhesive additives, non-polymer adhesive additives, etc., to achieve the effects of improving storage period, long-term anti-mildew and antibacterial efficacy, and controllable reaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

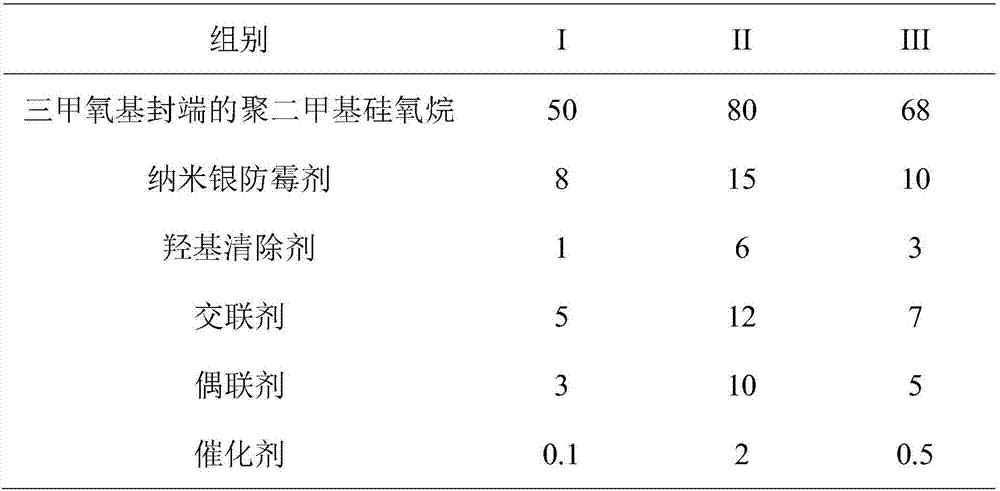

[0026] Embodiment 1: the preparation ratio of each raw material in the long-acting mildew-resistant sealant composition

[0027] The raw materials in the long-acting mildew-proof sealant composition were mixed according to the mass parts described in Table 1, and three groups of long-acting mildew-proof sealant compositions I to III with different mixing ratios were obtained.

[0028] The long-acting mildew-resistant sealant composition of different mixing ratios (parts by mass) of table 1

[0029]

Embodiment 2

[0030] Embodiment 2: the preparation method of the long-acting mildew-resistant sealant composition

[0031] Step 1. Preparation of silicon-nitrogen heterocyclic compound: put trifluoromethanesulfonic acid and silane compound with a molar ratio of 1:1500 into the reaction kettle, carry out intramolecular cyclization reaction, heat to reflux state, and the reaction time is 5-20h , stop the reaction when the reaction no longer generates alcohol, and distill to obtain the silicon nitrogen heterocyclic compound.

[0032] Described silane compound is shown in the following formula:

[0033] where n=2;

[0034] The acid is one of fluorosulfonic acid, benzenesulfonic acid and methanesulfonic acid.

[0035] Preparation of nano-silver antifungal agent: Dissolve glucose in deionized water, configure a solution with a molar concentration of 1.5mol / L, and place it in a hydrothermal reactor at 140-180°C for a reaction time of 8-20 hours; After completion, the resulting mixture was cen...

Embodiment 3

[0038] Embodiment 3: the preparation method of long-acting mold-proof sealant composition

[0039] Step 1. Preparation of silicon-nitrogen heterocyclic compound: put fluorosulfonic acid and silane compound with a molar ratio of 1:500 into the reactor, carry out intramolecular cyclization reaction, heat to reflux state, and the reaction time is 5-20h. Stop the reaction when alcohol is no longer generated, and distill to obtain the silicon nitrogen heterocyclic compound.

[0040] Described silane compound is shown in the following formula:

[0041] where n=4;

[0042] Described acid is a kind of in,,, benzenesulfonic acid, methanesulfonic acid.

[0043] Preparation of nano-silver antifungal agent: Dissolve glucose in deionized water, configure a solution with a molar concentration of 0.5mol / L, and place it in a hydrothermal reaction kettle for reaction at 140-180°C for 8-20 hours; After completion, the resulting mixture was centrifuged, washed with deionized water and absol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com