Copper masterbatch and preparation method thereof

A masterbatch and granulation technology, applied in the field of textile fibers, can solve the problems that the product cannot be white or light, the preparation method is complicated, and is not conducive to environmental protection, etc., to improve industrial application, maintain nano-activity, and have good antibacterial effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This embodiment provides a copper masterbatch and a preparation method thereof, comprising the following steps:

[0028] 1) Preparation of modified nano-copper: under the pressure of 0.1mbar ~ 0.1bar, in an inert gas environment, add high-purity copper powder into a vacuum high-speed disperser for nano-dispersion, and then vacuum-dry it in a vacuum drying pit furnace. Obtain nano-copper; modify nano-copper with coupling agent under vacuum conditions to obtain modified nano-copper;

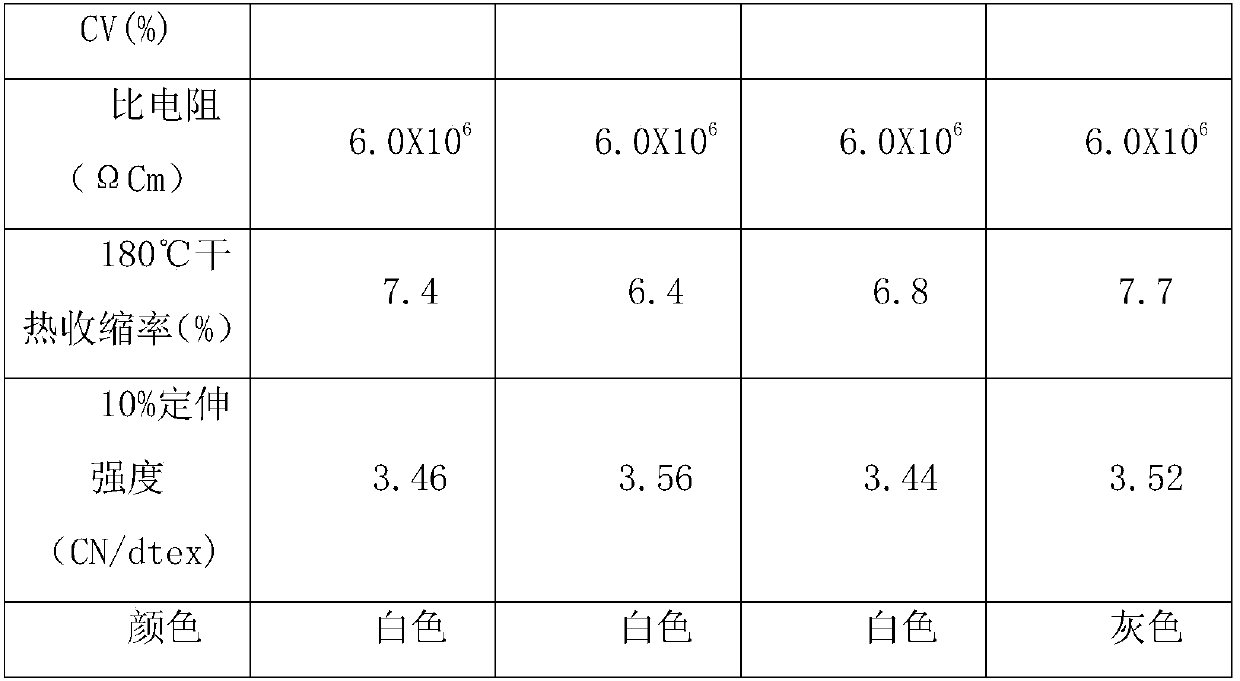

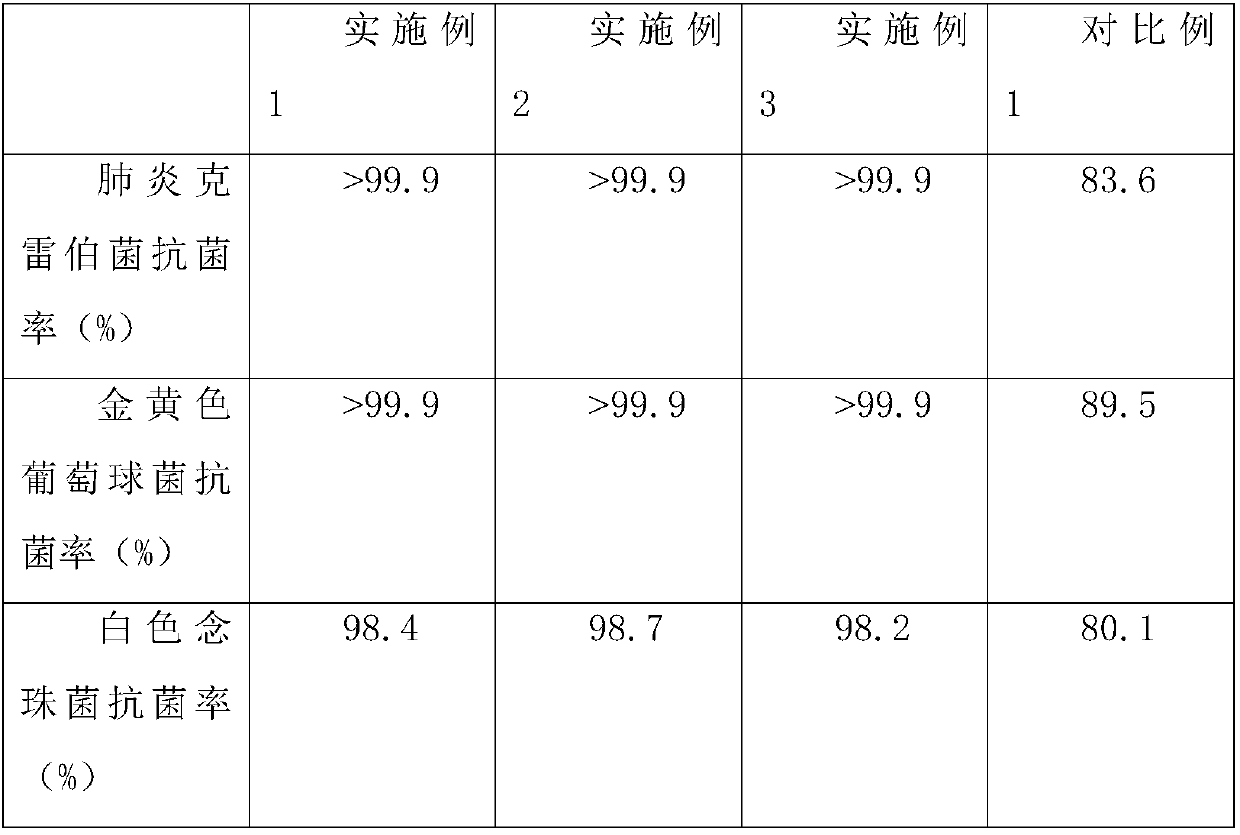

[0029] 2) Preparation of copper masterbatch: Add 20kg of modified nano-copper and 80kg of PET prepared in step 1) into a vacuum high-speed disperser, mix at 280°C and 0.1 bar to form a mixed solution; make the nano-copper on the PET substrate Evenly distributed in the inside; pour the mixed solution into a vacuum reaction granulator and carry out vacuum reaction granulation under the conditions of 320°C and 0.1mbar to obtain copper masterbatch. The prepared copper masterbatch is subjected t...

Embodiment 2

[0031] This embodiment provides a copper masterbatch and a preparation method thereof, comprising the following steps:

[0032] 1) Preparation of modified nano-copper: under the pressure of 0.1mbar ~ 0.1bar, in an inert gas environment, add high-purity copper powder into a vacuum high-speed disperser for nano-dispersion, and then vacuum-dry it in a vacuum drying pit furnace. Obtain nano-copper; modify nano-copper with surfactant under vacuum condition to obtain modified nano-copper;

[0033] 2) Preparation of copper masterbatch: Add 4kg of modified nano-copper and 96kg of PET prepared in step 1) into a vacuum high-speed disperser, mix at 380°C and 0.1mbar to form a mixed solution; make the nano-copper on the PET base Evenly distributed in the material; Pour the mixed solution into a vacuum reaction granulator for vacuum reaction granulation under the conditions of 50°C and 0.1bar to obtain copper masterbatch. The prepared copper masterbatch is subjected to rapid low-temperatu...

Embodiment 3

[0035] This embodiment provides a copper masterbatch and a preparation method thereof, comprising the following steps:

[0036] 1) Preparation of modified nano-copper: under the pressure of 0.1mbar ~ 0.1bar, in an inert gas environment, add high-purity copper powder into a vacuum high-speed disperser for nano-dispersion, and then vacuum-dry it in a vacuum drying pit furnace. Obtain nano-copper; modify nano-copper with organic oligomer under vacuum conditions to obtain modified nano-copper;

[0037] 2) Preparation of copper masterbatch: Add 10kg of modified nano-copper and 90kg of PET prepared in step 1) into a vacuum high-speed disperser, mix at 350°C and 0.5mbar to form a mixed solution; make the nano-copper on the PET base Evenly distributed in the material; pour the mixed solution into a vacuum reaction granulator and carry out vacuum reaction granulation under the conditions of 150°C and 0.5mbar to obtain copper masterbatch; perform rapid low-temperature freezing treatment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com