Composite plastic counter-weight shell

A composite plastic and casing technology, applied in the field of elevator processing, can solve problems such as large fluctuation, uncertain production cost, and harmful gas generation, and achieve the effects of reducing labor and manufacturing costs, reducing painting processes, and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

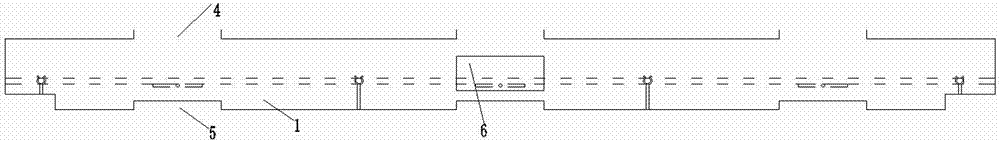

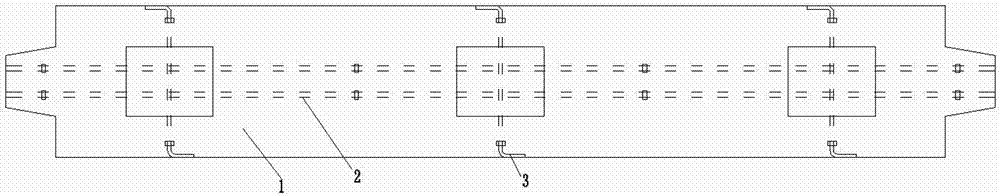

[0027] The present invention is a composite plastic counterweight casing, the casing is formed by one-time extrusion of the following composite materials, two parallel transverse connecting steel bars 2 are arranged transversely in the casing shell 1, along the There are three vertically connected steel bars 3 vertically, each of which is Z-shaped, and the horizontally connected steel bars and the longitudinally connected steel bars are respectively fixed by several Y-shaped quick buckles arranged inside the shell shell, and each horizontally The connecting steel bars are fixed by four Y-shaped quick buckles, and each longitudinal connecting steel bar is fixed by two Y-shaped quick buckles, which changes the original welding process between the iron shell and the steel bars, and now the plastic shell and the internal steel bars There is a direct buckle-type connection between them. There are multiple Y-shaped quick buckles at the placement of the steel bars inside the plastic s...

Embodiment 2

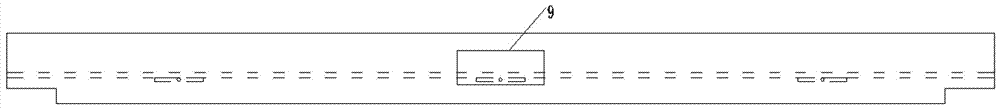

[0029] The present invention is a composite plastic counterweight shell. The shell is formed by one-time extrusion of the following composite materials. The upper end of the shell shell 1 is open, and two parallel horizontal steel bars are arranged horizontally in the shell 1. 7. Three longitudinal steel bars 8 are arranged longitudinally in the housing 1, the longitudinal steel bars 8 are Z-shaped, and the transverse steel bars 7 and the longitudinal steel bars 8 are directly prepared as reinforcement cages and placed in the housing 1. 1 is also provided with a second signboard 9 for placing the LOGO, the thickness of the shell is 1-1.2mm, and the shell is prepared by the following element components according to the weight percentage, including 45 parts by weight of polyvinyl chloride resin, reinforced 15 parts by weight of fiber, 5 parts by weight of plasticizer, 25 parts by weight of barium sulfate powder, 50 parts by weight of calcium carbonate powder, 0.5 parts by weight ...

Embodiment 3

[0031] The present invention is a composite plastic counterweight shell, which is extruded at one time from the following composite materials, and the shell is prepared from the following elemental components according to weight percentage, including 60 parts by weight of polyvinyl chloride resin, reinforcing fiber 10 parts by weight, 10 parts by weight of plasticizer, 40 parts by weight of barium sulfate powder, 65 parts by weight of calcium carbonate powder, 1 part by weight of stabilizer, 1 part by weight of stearic acid, 1 part by weight of polyethylene wax, 2 parts by weight of modifier part, 1 part by weight of flame retardant, and 1 part by weight of pigment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com