Preparation method of fiber material with low-frequency sound absorption and insulation functions

A sound absorption and sound insulation, fiber material technology, applied in the field of sound absorption materials, can solve the problems of poor flame retardancy, corrosion resistance and moisture resistance, easy to cause pollution, weak sound absorption ability, etc., to achieve low cost, increased surface area, good The effect of sound absorption and sound insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1. Put sisal fibers with a diameter of 100um and a length of 2mm into 20wt% NaOH aqueous solution, heat to 70°C and soak for 6h, then wash with water until neutral, and dry in a drying oven at 50°C.

[0029] 2. Mix the treated sisal fiber with an aqueous solution of 18wt% polyurethane adhesive at a mass ratio of 1:5, and stir at a high speed mechanically until the sisal fiber is uniformly suspended and dispersed in the mixture, which is recorded as sisal fiber suspension.

[0030] 3. The above-mentioned sisal fiber suspension is poured into a mould, and formed by a hot press forming process to obtain a fiber material with a low-frequency sound absorption and sound insulation function, with a thickness of 8mm; the hot press forming process is: the cast mold is heated The sound-absorbing material is obtained by hot-pressing and solidifying on a press molding machine. The hot-pressing time is 4-10 minutes, the hot-pressing temperature is 80-140° C., and the hot-pressing pre...

Embodiment 2

[0032] 1. Put sisal fibers with a diameter of 100um and a length of 2mm into 5wt% NaOH aqueous solution, heat to 70°C and soak for 6h, and then soak the alkali-treated sisal fibers in 15% H 2 o 2 In the aqueous solution, heat to 70°C and soak for 6 hours, then wash with water until neutral, and dry in a drying oven at 50°C.

[0033] 2. Mix the treated sisal fiber with an aqueous solution of 18wt% polyurethane adhesive at a mass ratio of 1:5, and stir at a high speed mechanically until the sisal fiber is uniformly suspended and dispersed in the mixture, which is recorded as sisal fiber suspension.

[0034] 3. The above-mentioned sisal fiber suspension is poured into a mould, and formed by a hot press forming process to obtain a fiber material with a low-frequency sound absorption and sound insulation function, with a thickness of 8mm; the hot press forming process is: the cast mold is heated The sound-absorbing material is obtained by hot-pressing and solidifying on a press mo...

Embodiment 3

[0036]1. Put sisal fibers with a diameter of 100um and a length of 2mm into 5wt% NaOH aqueous solution, heat to 70°C and soak for 6h, and then soak the alkali-treated sisal fibers in 15% H 2 o 2 In the aqueous solution, heat to 70°C and soak for 6 hours, then wash with water until neutral, and dry in a drying oven at 50°C.

[0037] 2. Mix the treated sisal fiber with an aqueous solution of 18wt% polyurethane adhesive at a mass ratio of 1:5, and stir at a high speed mechanically until the sisal fiber is uniformly suspended and dispersed in the mixture, which is recorded as sisal fiber suspension.

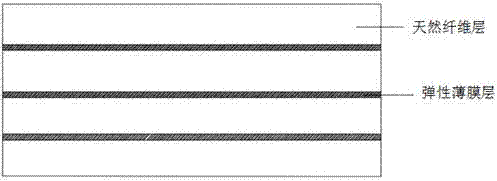

[0038] 1. First pour a layer of sisal fiber suspension into the model, then spread a layer of PE elastic film (thickness 0.05mm, the same below), then pour a layer of sisal fiber suspension, and then spread a layer of PE Finally, all the remaining sisal fiber suspension is poured into the mold, and hot-pressed to obtain a fiber material with low-frequency sound-absorbing and sound-i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com