Preparation method of nanometer self-compaction air setting mortar

An air-hardening and self-compacting technology, applied in the direction of additive processing, etc., to achieve the effects of improving fluidity, increasing strength, improving later strength and water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with specific examples.

[0013] In calcium sulfate, add organic interface agent, nano-mineral active agent, water-repellent agent, cross-linking agent, aggregate, and mix well to obtain dry mortar powder; add water to dry mortar powder, stir well, then pour into abrasive tools, Curing in the air for 1 day to obtain an air-hardening material.

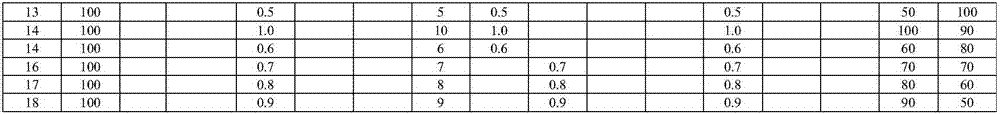

[0014] Table 1 lists 18 examples numbered 1-18.

[0015] Table 1

[0016]

[0017]

[0018] In 16 examples, the strength of the air-hardening material obtained is greater than 30MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com