Grinding method applied to inner surface of elbow pipe

A technology of inner surface and elbow, which is applied in the field of grinding the inner surface of the elbow, can solve the problems of reducing the polishing efficiency of the inner surface of the elbow, being easily eroded by the working medium, and accelerating the corrosion of oil on the pipeline, etc., to achieve the highest rotation efficiency Excellent, short working hours, quick replacement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

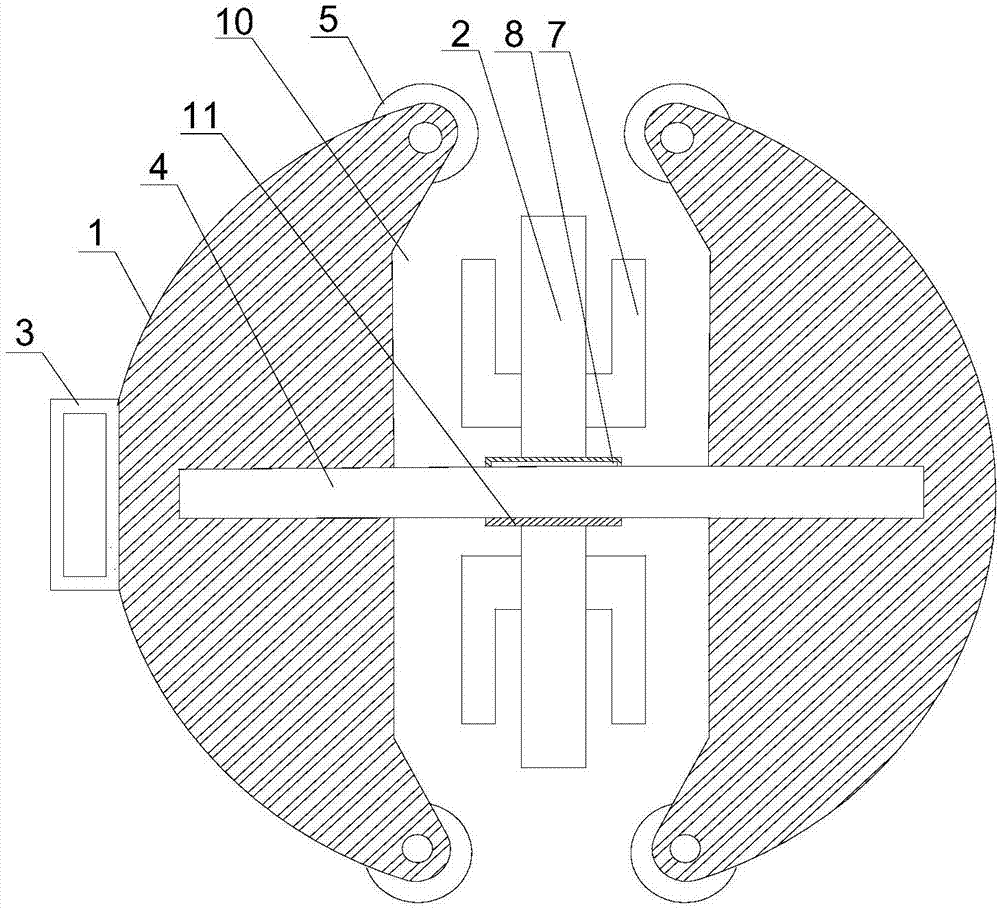

[0024] Such as figure 1 and figure 2 As shown, this embodiment includes the following steps: inject the working medium into the clamped and fixed petroleum elbow, enter the grinding head composed of two semi-circular spheres and the runner into the elbow, and the working medium flows from the grinding head and the elbow The flowing working medium drives the runner to rotate freely, and the runner sprays part of the working medium onto the pipe wall to assist in grinding the inner wall of the elbow. The working medium acts on the pipe wall On the surface, through the high-speed movement of abrasive particles, the corners or protruding parts on the inner wall of the elbow are sheared and removed, and the iron filings falling off the pipe wall are also cleaned when the working medium impacts the pipe wall;

[0025] Wherein, a sleeve 11 is provided in the middle part of the rotating shaft 4, and a strip-shaped protrusion 8 is provided on the outer wall of the middle part along t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com