High-pressure water jet flow three-dimensional self-rotation sprayer

A high-pressure water jet, self-rotating technology, applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of low cleaning pressure, clumsy cleaning method, short service life, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0022] The preferred embodiment of the high-pressure water jet three-dimensional self-rotating nozzle of the present invention is:

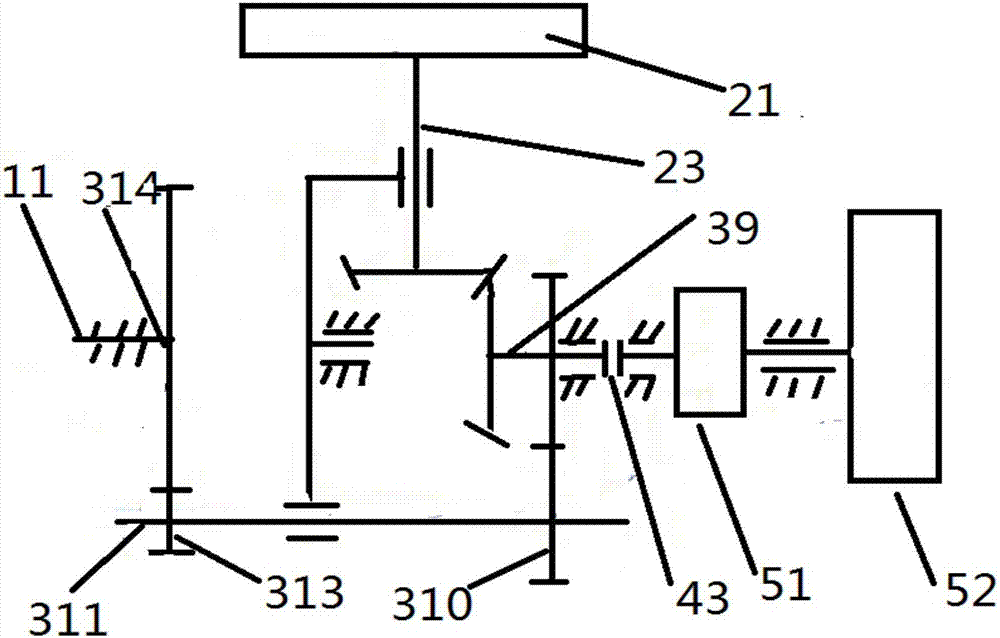

[0023] Including suspension inlet assembly, nozzle assembly, cross shaft core assembly, connecting device, brake assembly;

[0024] The overall mechanical structure of the cross shaft core assembly is divided into two parts, each part includes a planetary gear train, and the two gear trains are separated on different planes to form a whole space epicyclic gear train. and the gear shaft as the sun gear, the large planetary gear and the small planetary gear are installed on the planetary gear installation shaft, and the T-shaped housing is used as the planet carrier; the second planetary gear train also uses the gear shaft as the sun gear, and the nozzle seat As a planetary gear, it is installed on a hollow support shaft, and the T-shaped housing is also used as a planetary carrier.

[0025] The suspended inlet assembly includes a water inlet holl...

specific Embodiment

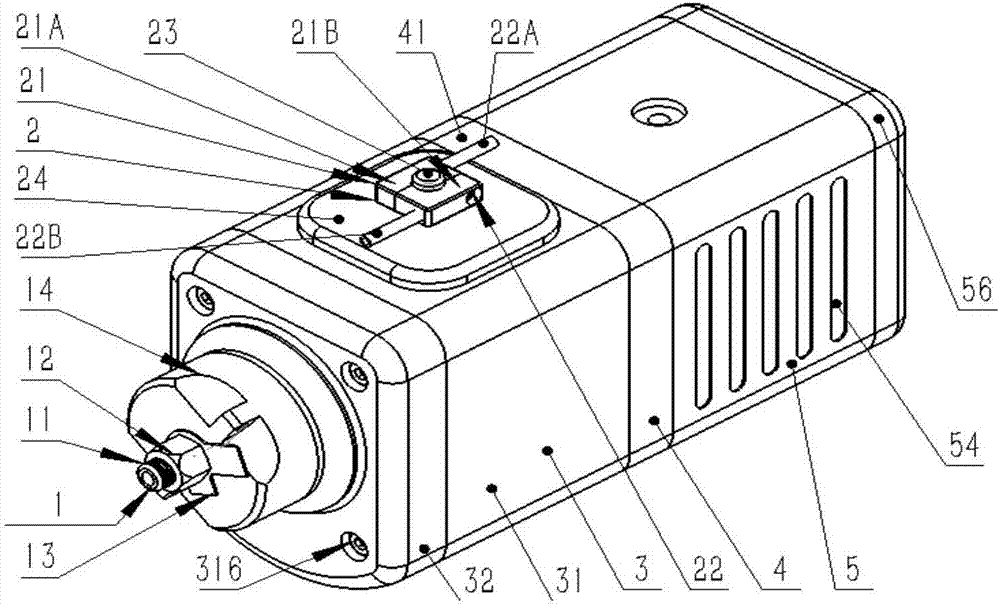

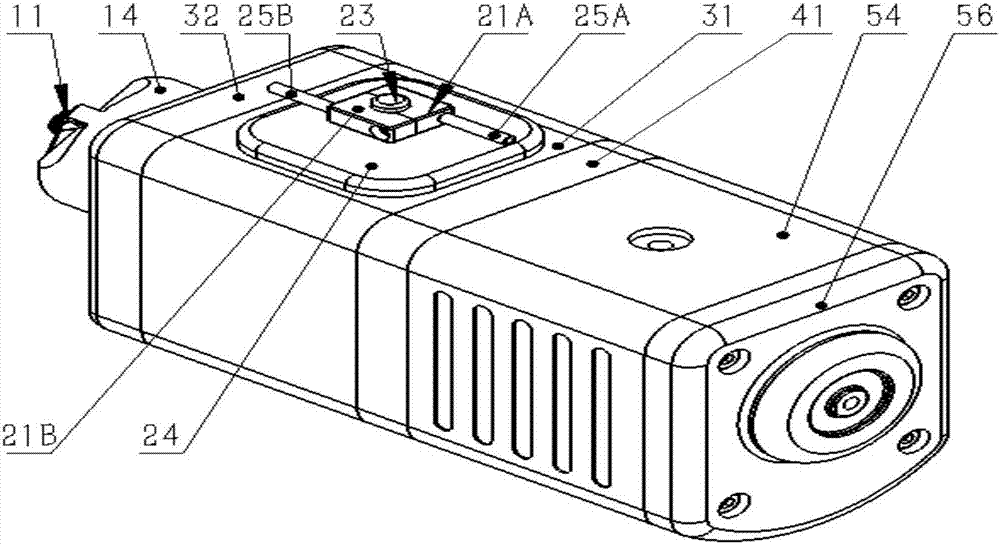

[0035] Such as Figure 1 to Figure 6 As shown, the high-pressure water jet three-dimensional self-rotating nozzle of the present invention is mainly composed of five parts such as a suspension inlet connection assembly 1, a nozzle assembly 2, a cross shaft core assembly 3, a connection device 4, and a brake assembly 5.

[0036] The suspension inlet connection assembly 1 is composed of a water inlet hollow shaft 11, a lock nut 12, a lock washer 13 and a limit gland 14. The metal connector at the end of the high-pressure water pipe is connected to the water inlet hollow shaft through a pipe thread And sealed, the three-dimensional self-rotating nozzle is suspended and fixed on the nozzle frame by the two ears on the limit gland 14 to realize the cleaning operation, the limit gland 14 is pressed and fixed on the water inlet hollow by the lock nut 12 and the lock washer 13 On the shaft 11 , the water inlet hollow shaft 11 is connected to the cross shaft core assembly 3 . The wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com