Water storage tank and water heater

A technology for water heaters and water storage tanks, applied to fluid heaters, lighting and heating equipment, etc., can solve problems such as cumbersome work, damage, and component consumption, and achieve the effects of reducing costs, ensuring high-efficiency work, and facilitating the display of dirt deposits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

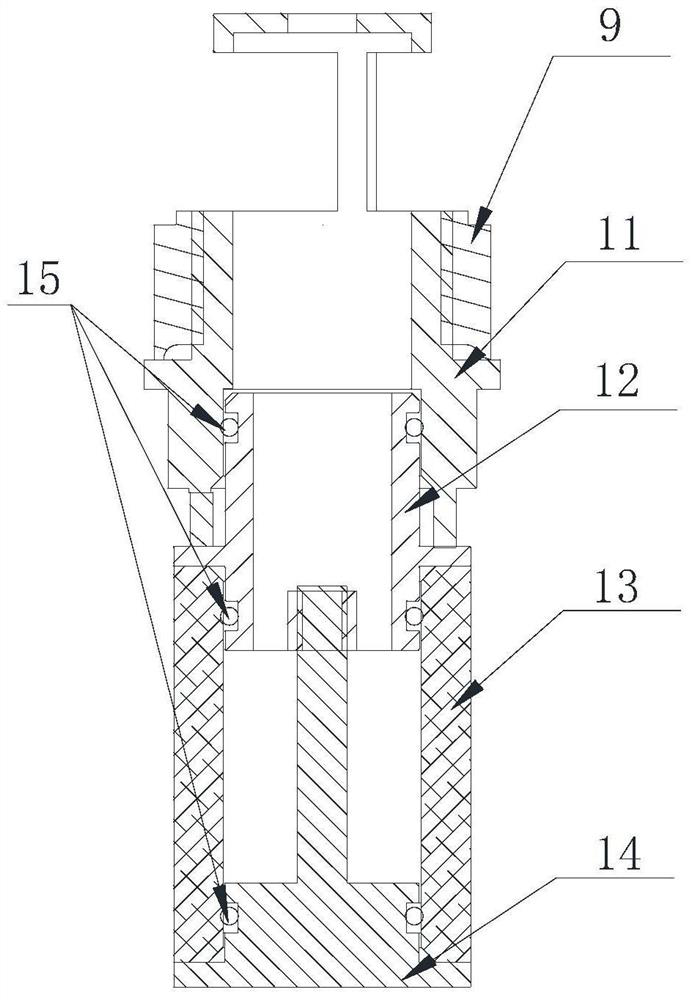

[0069] The only difference between this embodiment and the above-mentioned embodiments is that the transparent component 10 of this embodiment also has drainage / sewage discharge functions, specifically, the following technical solutions are adopted:

[0070] Such as Figure 7 As shown, one end of the lower connector 14 of this embodiment is sealed and installed on the other end of the transparent tube 13 and communicated with it, and the other end extends downward to form a drain pipe. The end of the drain pipe is provided with a drain port 36. The lower connection A drain valve 34 for controlling its on-off is arranged on the drain pipe of the part 14.

[0071] The lower connecting piece 14 of this embodiment closes the other end of the transparent tube 13 when the drain valve 34 is closed, and is used to display the amount of fouling in the inner tank of the water heater. And when drainage / sewage is required, only the drain valve 34 needs to be opened, and the lower connect...

Embodiment 2

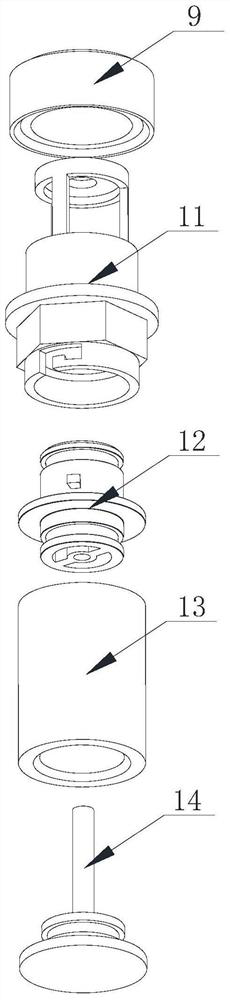

[0075] Such as Figure 8 and Figure 9 As shown, the difference between this embodiment and the above-mentioned embodiments is only that the transparent tube 13 of this embodiment is a U-shaped transparent tube with one end open and one end closed. Since the U-shaped transparent tube in this embodiment has only one end opening, the lower connector 14 is no longer provided in this embodiment, and the transparent tube 13 in this embodiment is connected to the magnesium rod bracket 11 through the upper connector 12 .

[0076] In order to ensure the stability of the connection between the U-shaped transparent tube and the upper connector 12, the upper opening of the U-shaped transparent tube is turned outward to form a mounting part, and the upper connector 12 is clamped by the buckle structure. The installation part of the type transparent tube.

Embodiment 3

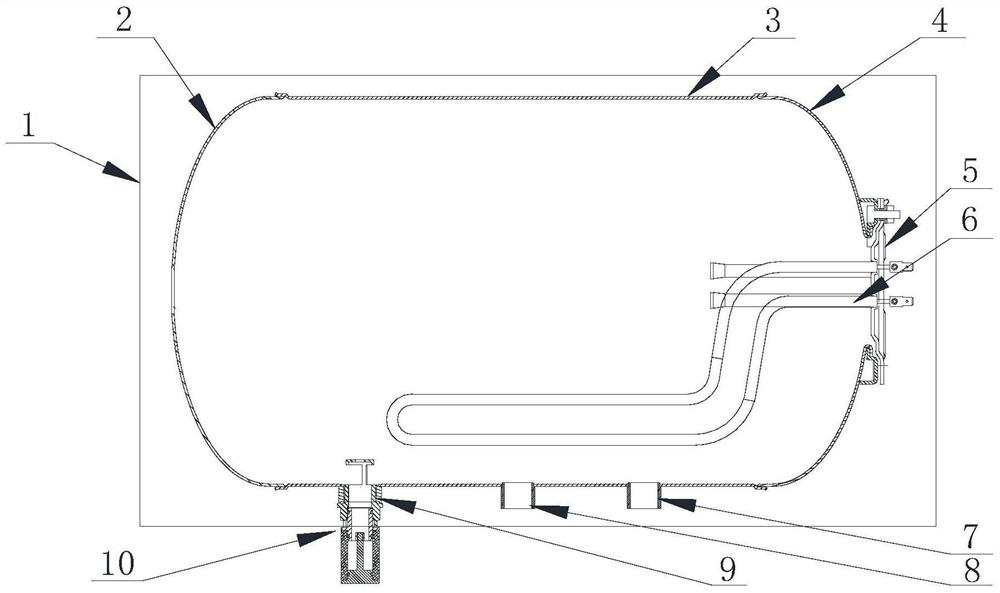

[0078] This embodiment provides a water heater adopting the above-mentioned storage tank of the water heater, which includes an outer shell 1 and an inner container arranged inside the outer shell 1, and is characterized in that an opening is provided on the outer shell 1 at a position corresponding to the installation position of the transparent component 10, The transparent part 13 of the transparent component 10 protrudes from the casing 1 through the opening.

[0079] The water heater of this embodiment adopts the above-mentioned water storage tank, and the transparent component 10 is installed on the outside of the shell 1, so that the user or maintenance personnel can observe the dirt deposition inside the inner tank at any time without disassembling the shell 1.

[0080] Further, the clamping part 19 of the magnesium rod bracket 11 is arranged on the outside of the shell 1, so that users or maintenance personnel can dismantle the transparent component 10, and the limitin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com