A steel grouting sleeve for ductile connection of prefabricated concrete structures

A technology for concrete structures and grouting sleeves, applied in the directions of structural elements, building components, building structures, etc., can solve the problem of forming plastic hinges in difficult connection parts, and achieve the effect of enhancing seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

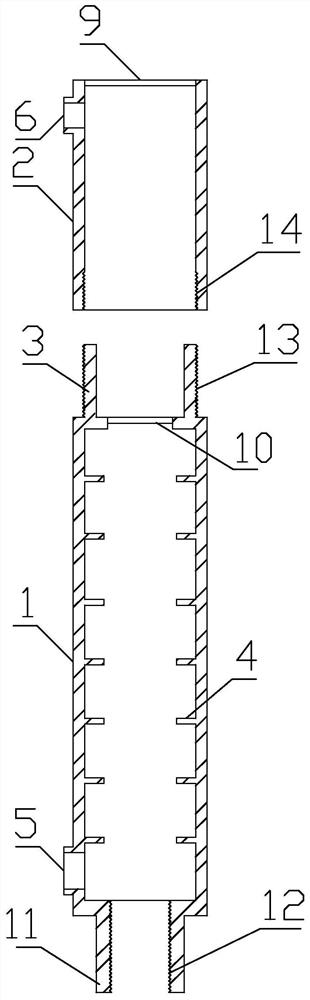

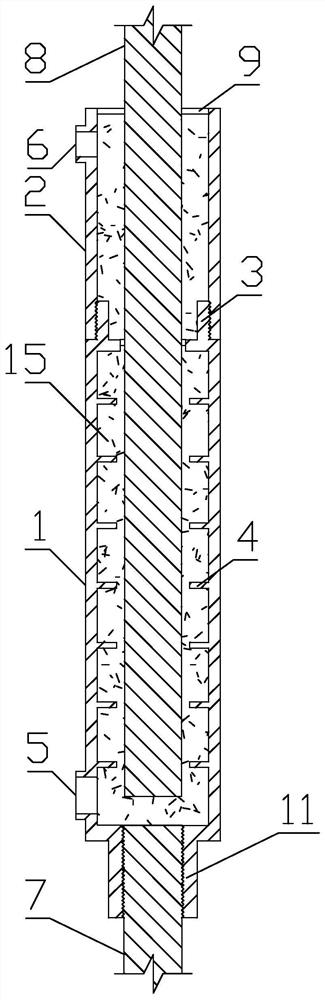

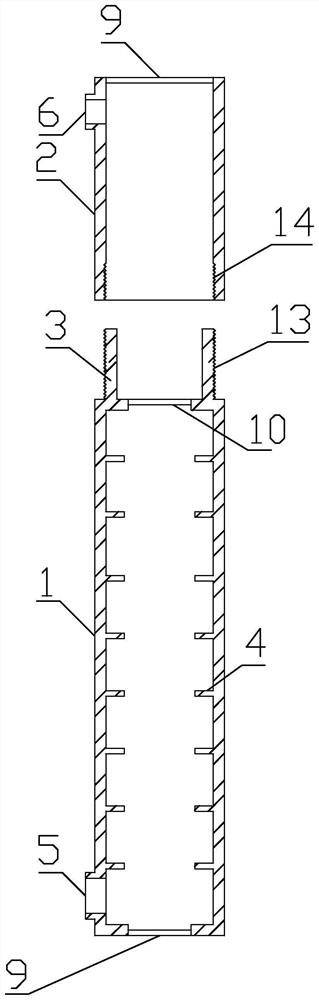

[0025] Such as figure 1 , 2 As shown, Example 1 of the present invention is used for the reinforced semi-grouting sleeve for the ductile connection of prefabricated concrete structures, including two sections of sleeves, grouting holes 5 and grouting holes 6, and the two sections of sleeves are the first section of grouting sleeve and The second section of the through sleeve, the first section of the grouting sleeve is used as the connector of the steel bar, and the second section of the through sleeve is the through tube of the steel bar. The first section of the grouting sleeve includes the grouting sleeve body 1 and the positioning teeth 3, the second section of the through sleeve includes the through sleeve body 2, the positioning teeth 3 are located at the upper end of the grouting sleeve body 1, and the outer diameter of the positioning teeth 3 is the same as th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com