Metal surface cleaning agent, preparation method, and method for cleaning metal surface

A metal surface and cleaning agent technology, applied in the field of metal surface treatment, can solve the problems of large environmental pollution and complex cleaning process, and achieve the effect of simplifying the process flow, improving environmental protection performance, reducing waste liquid treatment and water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

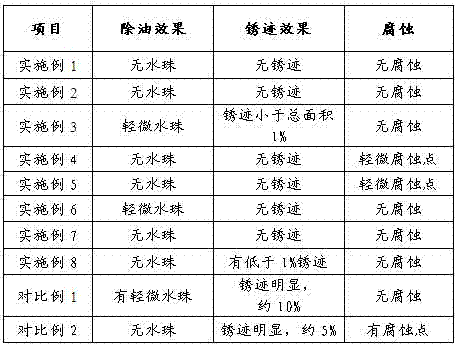

Examples

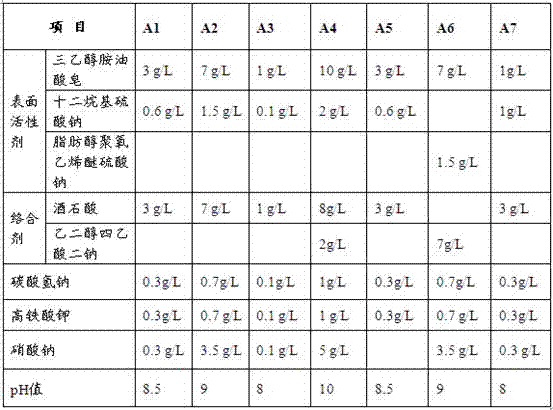

Embodiment 1-7

[0024] 1. Preparation of metal surface cleaning agent: add surfactant, emulsifier, complexing agent, sodium bicarbonate and ferrate into deionized water. Metal surface cleaners A1-A7 were obtained according to the ancestral grave ratio in Table 1, and the specific dosage of each group is shown in Table 1.

[0025] 2. Put a 2×2 cm magnesium alloy sample (brand AZ91D) into the cleaning agent in step (1) for cleaning to obtain a cleaned magnesium alloy sample. The cleaning temperature is 40° C., and the cleaning time is 5 minutes.

Embodiment 8

[0027] 1. Put a 2×2 cm aluminum alloy sample (grade 6061) into the cleaning agent A1 obtained in Example 1 for cleaning to obtain a cleaned aluminum alloy sample. The cleaning temperature is 60° C., and the cleaning time is 5 minutes.

[0028] Table 1

[0029]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com