High-hardness additive manufacturing tool

An additive manufacturing, high hardness technology, applied in metal material coating technology, coating, metal processing and other directions, can solve the increase of high-end tool manufacturing cost, difficult to meet the high-end tool high hardness, high wear resistance and other performance requirements and other problems to achieve the effect of enhancing market competitiveness, reducing production costs and reducing import volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

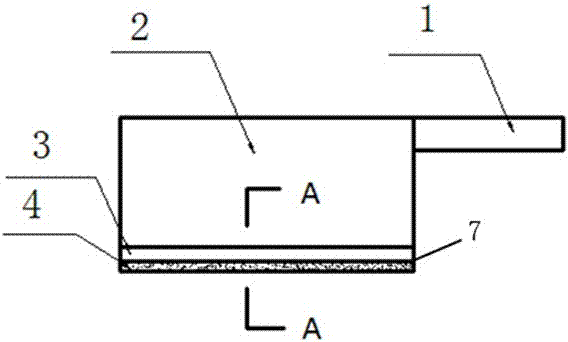

[0019] Taking the dagger as an example, the production of the knife is described as follows:

[0020] The iron-based alloy powder is ball-milled, dried and placed in a powder feeder. The iron-based alloy powder is composed of 0.6% carbon, 23% chromium, 1% silicon, 1% boron, 6.5% nickel, and 1% manganese by mass percentage. , molybdenum 0.2%, iron 66.7%, powder size range is 125um.

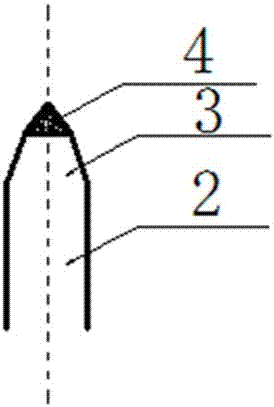

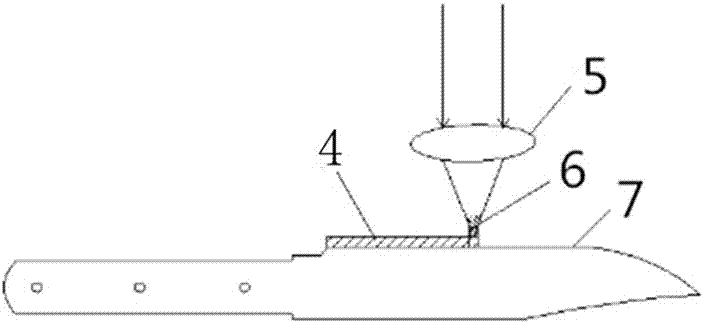

[0021] The material of the blade 2 is 3Cr13, the thickness is 2.5mm, and the blade 3 of the blade 2 is polished to remove rust, and then the surface of the blade is cleaned, and then the blade is fixed with a special clamp; then the edge line 7 of the blade 3 of the blade 2 is The laser performs additive manufacturing by means of coaxial powder feeding to prepare the additive manufacturing strengthening layer 4. The thickness of the prepared additive manufacturing strengthening layer 4 is 2.3mm. The additive manufacturing process parameters are laser power 1.5KW, scanning speed 25mm / s, The spot di...

Embodiment 2

[0026] The iron-based alloy powder is ball-milled and then dried and placed in a powder feeder. The iron-based alloy powder is composed of 1.5% carbon, 35% chromium, 2.5% silicon, 2% boron, 12% nickel and 2% manganese by mass percentage. , molybdenum 0.3%, iron 44.7%, powder size range is 275um.

[0027] The material of the blade 2 is 3Cr13, the thickness is 2.5mm, and the blade 3 of the blade 2 is polished to remove the rust, and then the surface oil of the blade 3 is cleaned, and then the blade is fixed with a special clamp; Additive manufacturing is carried out by using laser through coaxial powder feeding to prepare additive manufacturing strengthening layer 4, the prepared additive manufacturing strengthening layer 4 is 2.35mm, and the additive manufacturing process parameters are laser power 1.5KW, scanning speed 25mm / s, The spot diameter is 1.5mm, the powder feeding speed is 32g / min, the preheating temperature is 300°C, the postheating temperature is 200°C, the postheat...

Embodiment 3

[0032] The iron-based alloy powder is ball-milled, dried and placed in a powder feeder. The iron-based alloy powder is composed of 1.0% carbon, 28% chromium, 1.5% silicon, 1.2% boron, 10% nickel, and 1.5% manganese by mass percentage. , molybdenum 0.25%, iron 56.55%, the powder size range is 275um.

[0033] The material of the blade 2 is 3Cr13, the thickness is 2.5mm, and the blade 3 of the blade 2 is polished to remove the rust, and then the surface oil of the blade 3 is cleaned, and then the blade is fixed with a special clamp; Additive manufacturing is carried out by using laser through coaxial powder feeding to prepare additive manufacturing strengthening layer 4, the prepared additive manufacturing strengthening layer 4 is 2.35mm, and the additive manufacturing process parameters are laser power 1.5KW, scanning speed 25mm / s, The spot diameter is 1.5mm, the powder feeding speed is 32g / min, the preheating temperature is 300°C, the postheating temperature is 200°C, the posth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com