Damage-tolerant aluminum material with layered microstructure

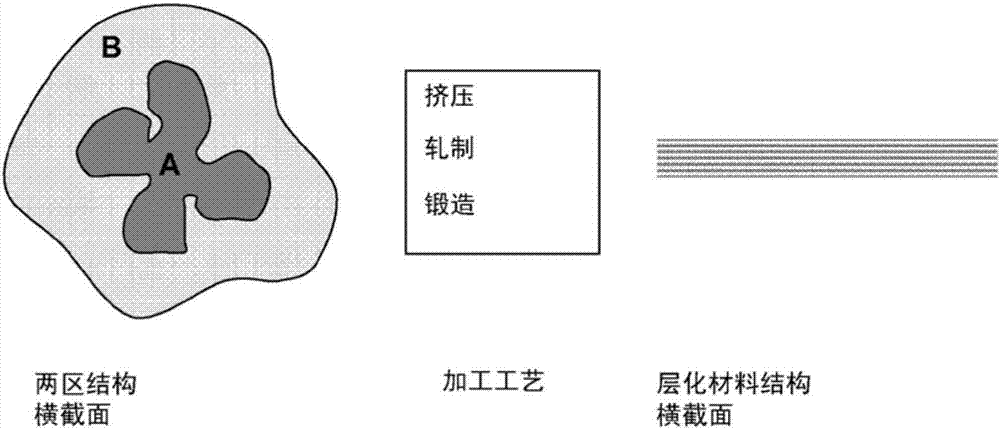

A technique for casting aluminum, forging aluminum, applied to the alloy including the following components based on weight %: up to 0.6, preparing the aluminum material, containing a grain composition with 2 regions, preparation of damage-tolerant wrought aluminum material It can solve problems such as the inability to produce high damage tolerance materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0061] Table 1 lists the chemical composition in weight percent of some comparative materials (alloys C, E, F, G) and alloys within the scope of the invention (alloys A, B, D). All these aluminum alloys were DC cast to evaluate the effect of composition and casting speed on the development of peritectic components.

[0062] Table 2 lists the alloys and casting speeds of some comparative variants and variants which lead to a cast structure with a peritectic composition of more than 20% according to the invention (variants A2, A3 and B2, B3).

[0063] Cast bodies with a diameter of 254 mm and a peritectic composition of more than 20% (variants A2, B2 and D) and comparative materials (alloys C, E-G) were processed by the following steps:

[0064] Homogenize at 545°C;

[0065] air cooling;

[0066] Preheat to about 460°C;

[0067] Extrude into a box profile with a 2-hole die;

[0068] Press quenching with water;

[0069] Aged with different grains.

[0070] Comparing alloys ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| directional tensile yield strength | aaaaa | aaaaa |

| distribution coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com