High-strength energy-saving type surface layer plastering gypsum and preparation process thereof

An energy-saving plaster plaster technology, which is applied in the field of high-strength energy-saving surface plaster plaster and its preparation technology, can solve problems such as unstable performance of plaster plaster materials, lack of thermal insulation and humidity control effects, and complex preparation of phase change materials. Achieve the effect of good water retention performance, excellent thermal insulation and sound insulation, and a wide range of raw material sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

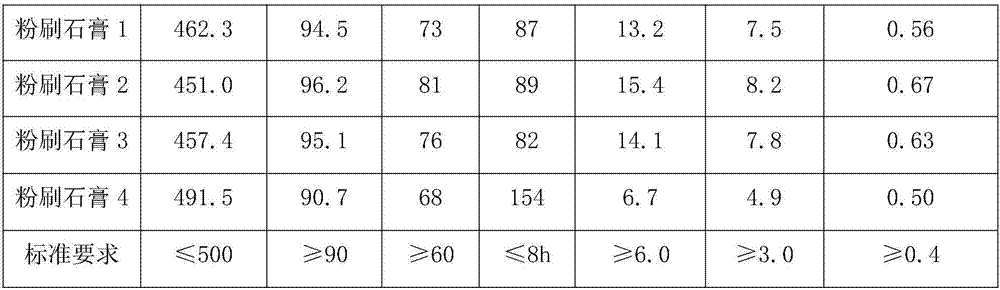

Embodiment 1

[0033] A high-strength energy-saving surface plaster plaster, weighing the following raw materials: 30kg of desulfurized hemihydrate gypsum, 25kg of modified diatomite, 20kg of fly ash, 15kg of double fly powder, 10kg of attapulgite powder, 8kg of polypropylene fiber, starch sticky Mixture 5kg, retarder 1kg, water reducer 1kg, water retention agent 1kg, foaming agent 1kg, foam stabilizer 1kg;

[0034] The modified diatomite is made from the following raw materials: 30kg of diatomite, 8kg of titanium dioxide, 3kg of lignin, 10kg of expanded perlite, 6kg of ferric chloride, 3kg of n-butyraldehyde-aniline condensate, 3kg of praseodymium oxide, Beeswax 6kg; the preparation method is to soak the diatomite in 5% hydrochloric acid solution for 40 minutes, dry the obtained material after suction filtration, mix it with the expanded perlite, and carry out high-temperature heating at 750°C. Calcinate for 1 hour, take it out and cool it to room temperature, then mix it with beeswax, grin...

Embodiment 2

[0046] A high-strength energy-saving surface plaster plaster, weighing the following raw materials: 40kg of desulfurized hemihydrate gypsum, 30kg of modified diatomite, 25kg of fly ash, 20kg of double fly powder, 15kg of attapulgite powder, 10kg of polypropylene fiber, starch sticky Mixture 10kg, retarder 3kg, water reducer 2kg, water retention agent 2kg, foaming agent 2kg, foam stabilizer 2kg;

[0047]The modified diatomite is made from the following raw materials: 30kg of diatomite, 8kg of titanium dioxide, 3kg of lignin, 10kg of expanded perlite, 6kg of ferric chloride, 3kg of n-butyraldehyde-aniline condensate, 3kg of praseodymium oxide, Beeswax 6kg; the preparation method is to soak the diatomaceous earth in 8% hydrochloric acid solution for 50 minutes, dry the obtained material after suction filtration, mix with the expanded perlite, and carry out high-temperature heating at 780°C. Calcinate for 1.5 hours, take it out and cool it to room temperature, then mix it with bee...

Embodiment 3

[0059] A high-strength energy-saving surface plaster plaster, the following raw materials are weighed: 50kg of desulfurized hemihydrate gypsum, 35kg of modified diatomite, 30kg of fly ash, 25kg of double fly powder, 20kg of attapulgite powder, 12kg of polypropylene fiber, starch sticky Mixture 15kg, retarder 5kg, water reducer 3kg, water retention agent 3kg, foaming agent 3kg, foam stabilizer 3kg;

[0060] The modified diatomite is made from the following raw materials: 30kg of diatomite, 8kg of titanium dioxide, 3kg of lignin, 10kg of expanded perlite, 6kg of ferric chloride, 3kg of n-butyraldehyde-aniline condensate, 3kg of praseodymium oxide, Beeswax 6kg; the preparation method is to soak the diatomite in 10% hydrochloric acid solution for 60 minutes, dry the obtained material after suction filtration, mix with the expanded perlite, and carry out high-temperature heating at 800°C. Calcinate for 2 hours, take it out and cool it to room temperature, then mix it with beeswax, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com