Jun porcelain bluish-white glaze

A technology of blue-white and Jun porcelain, applied in the field of Jun porcelain blue-white glaze, can solve the problems of low yield, irreparable products, polluting the environment, etc., and achieve the effect of strong jade texture and beneficial to human health.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

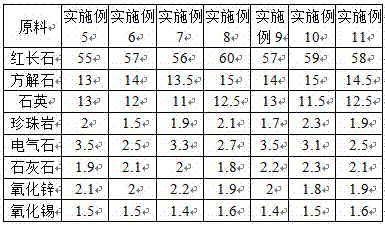

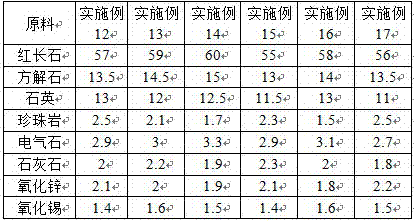

[0014] A bluish-white glaze for Jun porcelain, which is prepared from the following raw materials in parts by weight: 55-60 parts of red feldspar, 13-15 parts of calcite, 11-13 parts of quartz, 1.5-2.5 parts of perlite, and 2.5-3.5 parts of tourmaline , 1.8-2.3 parts of limestone, 1.8-2.2 parts of zinc oxide, 1.4-1.6 parts of tin oxide.

[0015] The preparation method of above-mentioned Jun porcelain bluish-white glaze, comprises the following steps:

[0016] (1) Mix the above raw materials with water, and ball mill to obtain glaze slurry;

[0017] (2) Glazing;

[0018] (3) Firing, the firing temperature is 1280-1300°C.

[0019] The firing process specifically includes the following steps: ① Oxidation period: Put the glazed green body into the kiln, and fire it in an oxidizing atmosphere, so that the temperature rises to 900-1000 ° C evenly in 3.5-5 hours; ② In a reducing atmosphere, The temperature is evenly raised to 1280-1300°C in 4-6h; ③Under a reducing atmosphere, keep...

Embodiment 2

[0023] A Jun porcelain bluish-white glaze, prepared from the following raw materials in parts by weight: 57.5 parts of red feldspar, 14 parts of calcite, 12 parts of quartz, 2 parts of perlite, 3 parts of tourmaline, 2.1 parts of limestone, 2 parts of zinc oxide, 1.5 parts of tin oxide.

[0024] The preparation method of above-mentioned Jun porcelain bluish-white glaze, comprises the following steps:

[0025] (1) Mix the above raw materials with water, and ball mill to obtain glaze slurry;

[0026] (2) Glazing;

[0027] (3) Firing, the firing temperature is 1290°C.

[0028] The firing process specifically includes the following steps: ① Oxidation period: Put the glazed green body into the kiln, and fire it in an oxidizing atmosphere, so that the temperature rises to 950°C evenly in 4 hours; Uniformly rise to 1290°C; ③Under reducing atmosphere, keep at 1290°C for 100min; ④Cool to room temperature to prepare.

[0029] The bluish-white glaze of Jun porcelain obtained by adopt...

Embodiment 3

[0031] A Jun porcelain bluish-white glaze, prepared from the following raw materials in parts by weight: 57.5 parts of red feldspar, 14 parts of calcite, 12 parts of quartz, 2 parts of perlite, 3 parts of tourmaline, 2.1 parts of limestone, 2 parts of zinc oxide, 1.5 parts of tin oxide.

[0032] The preparation method of above-mentioned Jun porcelain bluish-white glaze, comprises the following steps:

[0033] (1) Mix the above raw materials with water, and ball mill to obtain glaze slurry;

[0034] (2) Glazing;

[0035] (3) Firing, the firing temperature is 1300°C.

[0036] The firing process specifically includes the following steps: ① Oxidation period: Put the glazed green body into the kiln, and fire it in an oxidizing atmosphere, so that the temperature rises to 900 ° C evenly in 5 hours; ② In a reducing atmosphere, make the temperature in 4 hours Uniformly rise to 1300°C; ③Under reducing atmosphere, keep at 1300°C for 2h; ④Cool down to room temperature to prepare.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com