Multi-layer plastic transmitting film integrated sunshine greenhouse

An integrated, light-transmitting film technology, applied in horticulture, agriculture, climate change adaptation, etc., can solve the problems of short life of plastic greenhouses, achieve good thermal insulation, reduce area and distance, and strong firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with specific examples, but the present invention is not limited by the examples.

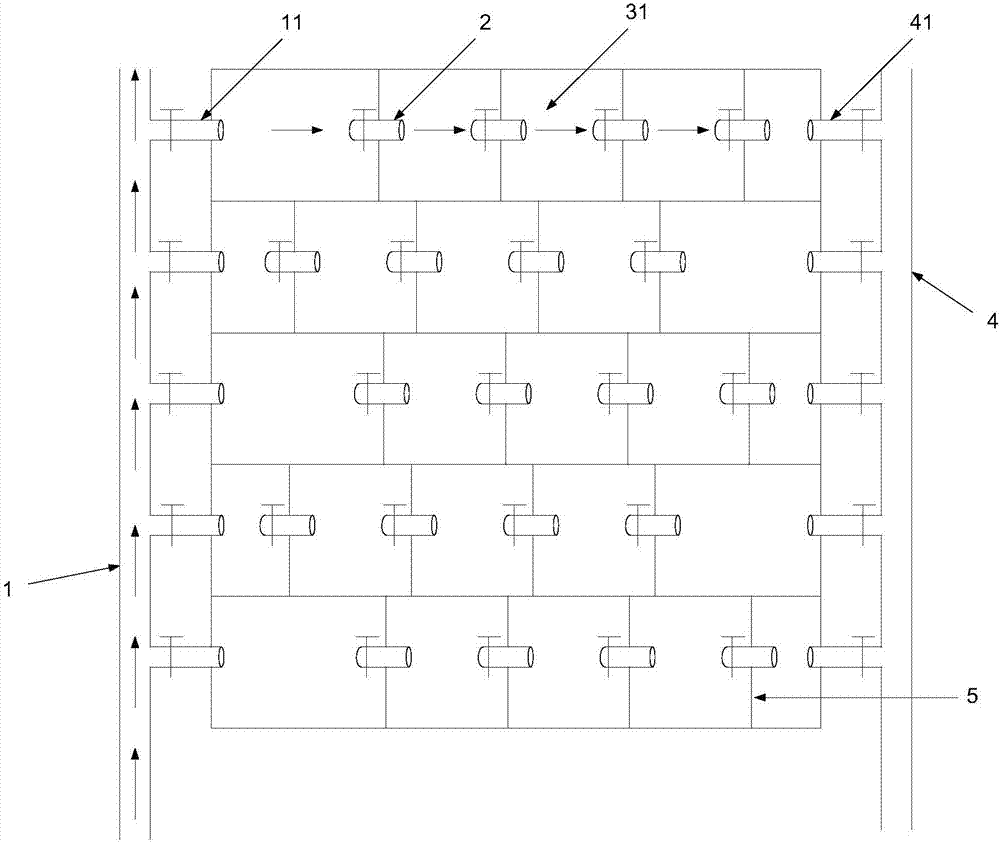

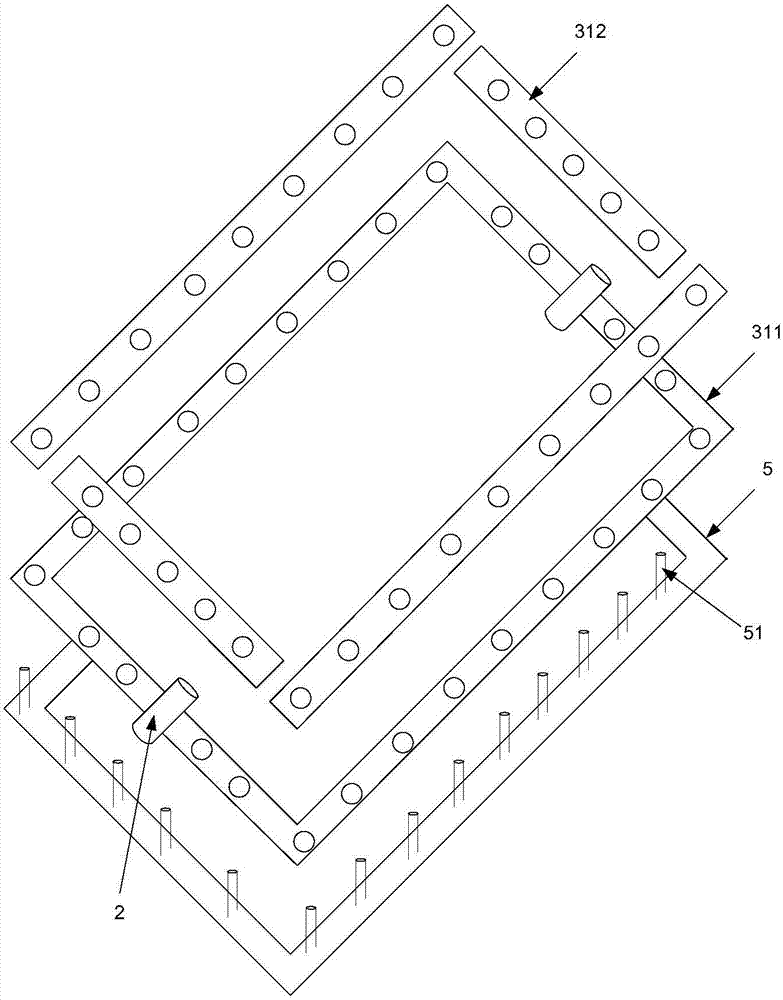

[0019] Such as Figure 1 to Figure 3 As shown, a multi-layer plastic light-transmitting film integrated sun shed, the sun shed includes an air inlet pressurized pipe 1, an air inlet pipe 2, a multi-layer plastic shed body 3 and an exhaust pipe 4; in the multi-layer plastic One side of the shed body 3 is provided with an air intake pressurization pipe 1; the other side of the multilayer plastic shed body 3 is provided with an exhaust pipe 4; the air intake pressurization pipe 1 is provided with a plurality of inflatable branch pipes 11; the exhaust pipe 4 is provided with a plurality of exhaust branch pipes 41; the inflatable branch pipes 11 correspond to the exhaust branch pipes 41 one by one; The branch pipe 11 is connected with the intake pressure pipe 1, and realizes inflating the multi-layer plastic shed body 3 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com