Rolling current-carrying friction abrasion tester

A technology of wear test and current-carrying friction, which is applied in the direction of testing wear resistance, etc., to prevent the temperature from being too high and prolong the test time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Through the following description of the embodiments, it will be more helpful for the public to understand the present invention, but the specific embodiments given by the applicant cannot and should not be regarded as limitations on the technical solutions of the present invention, any components or technical features Changes to the definition and / or formal but not substantive changes to the overall structure should be regarded as the scope of protection defined by the technical solutions of the present invention.

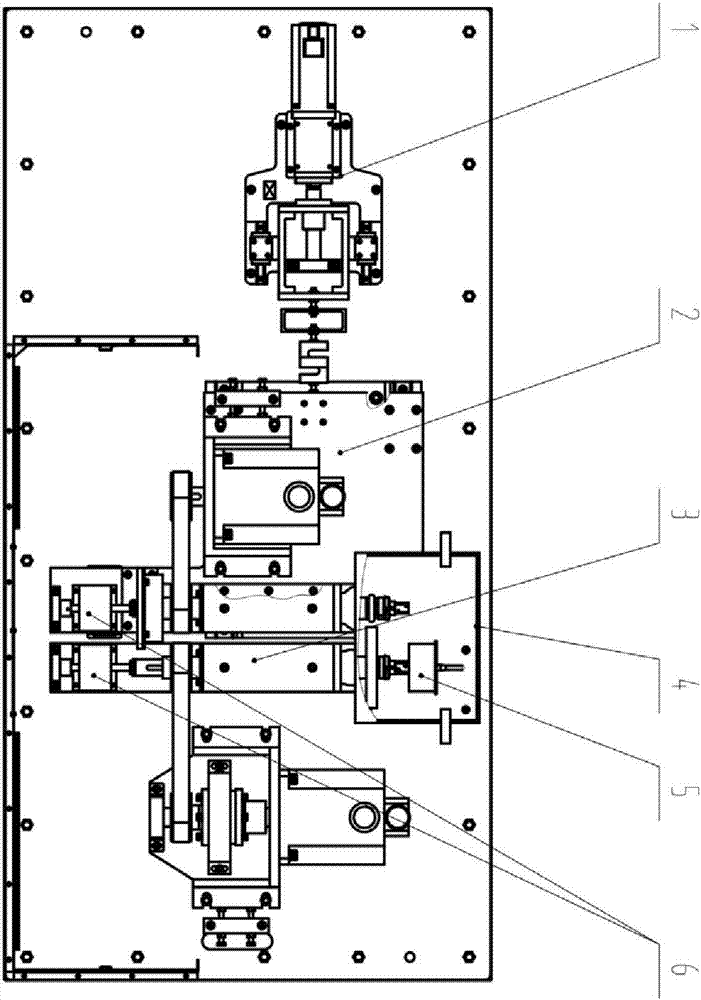

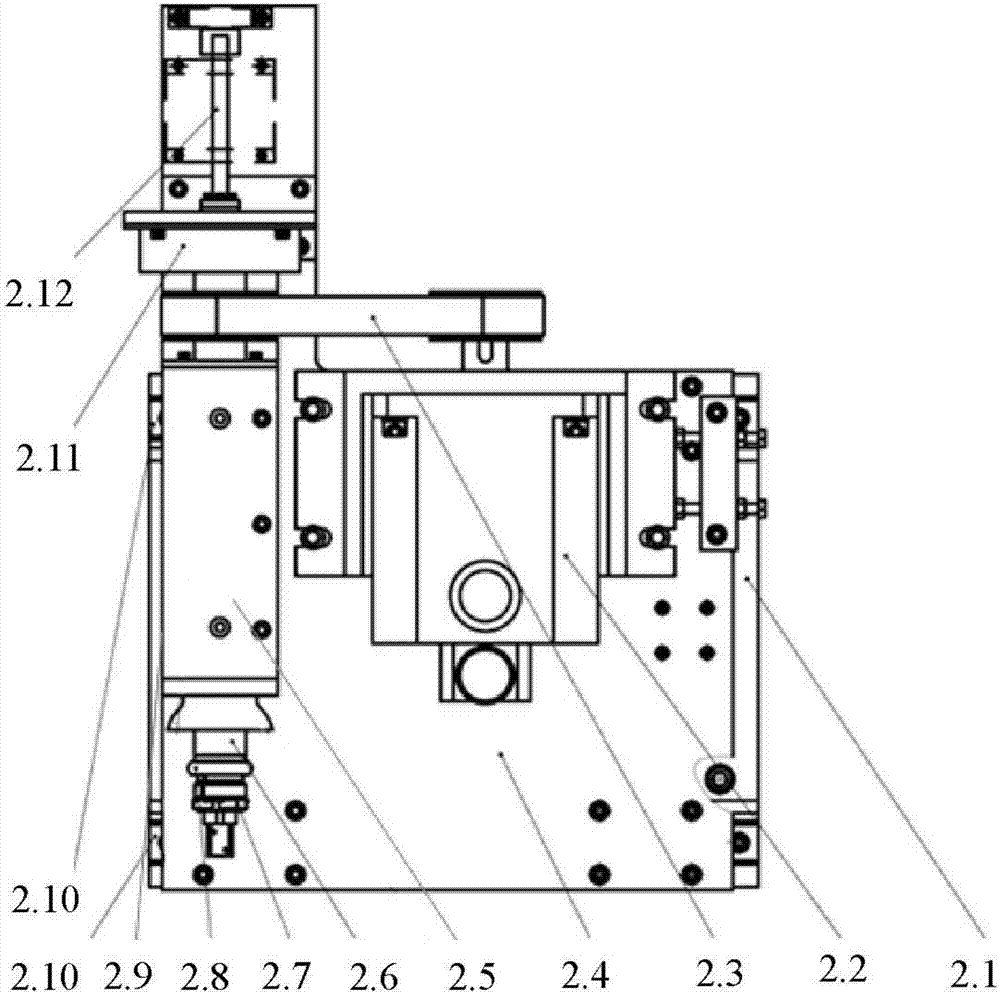

[0030] Such as figure 1 As shown, the main body of the rolling current-carrying friction and wear testing machine consists of a normal loading part 1, a moving shaft rolling platform 2, a fixed shaft rolling part 3, an air box 4, a wireless temperature measuring part 5, a liquid conductive part 6, a cooling and lubrication system, etc. components.

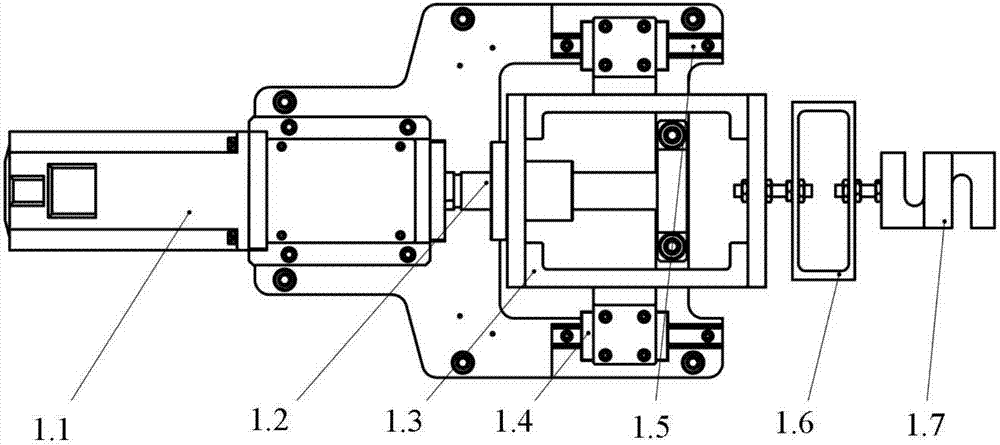

[0031] Such as figure 2 As shown, the normal loading part is used to load the normal force on the friction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com