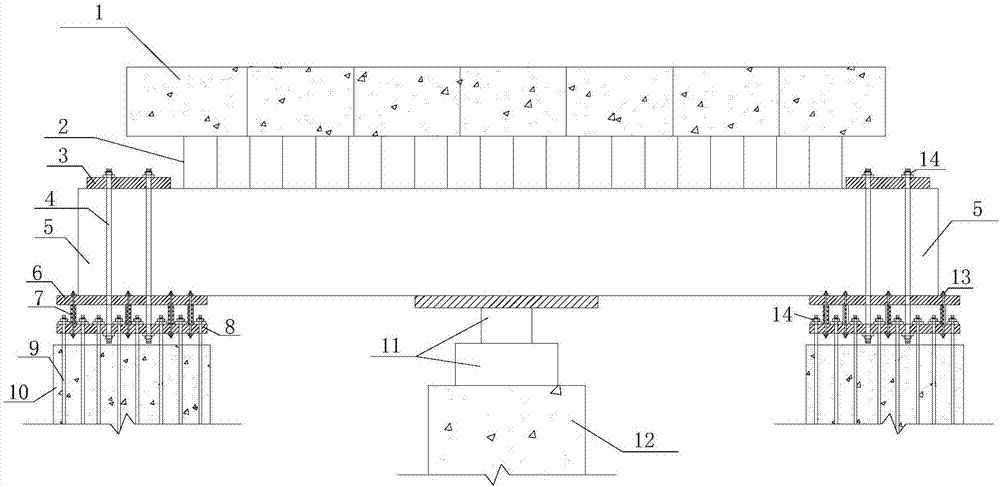

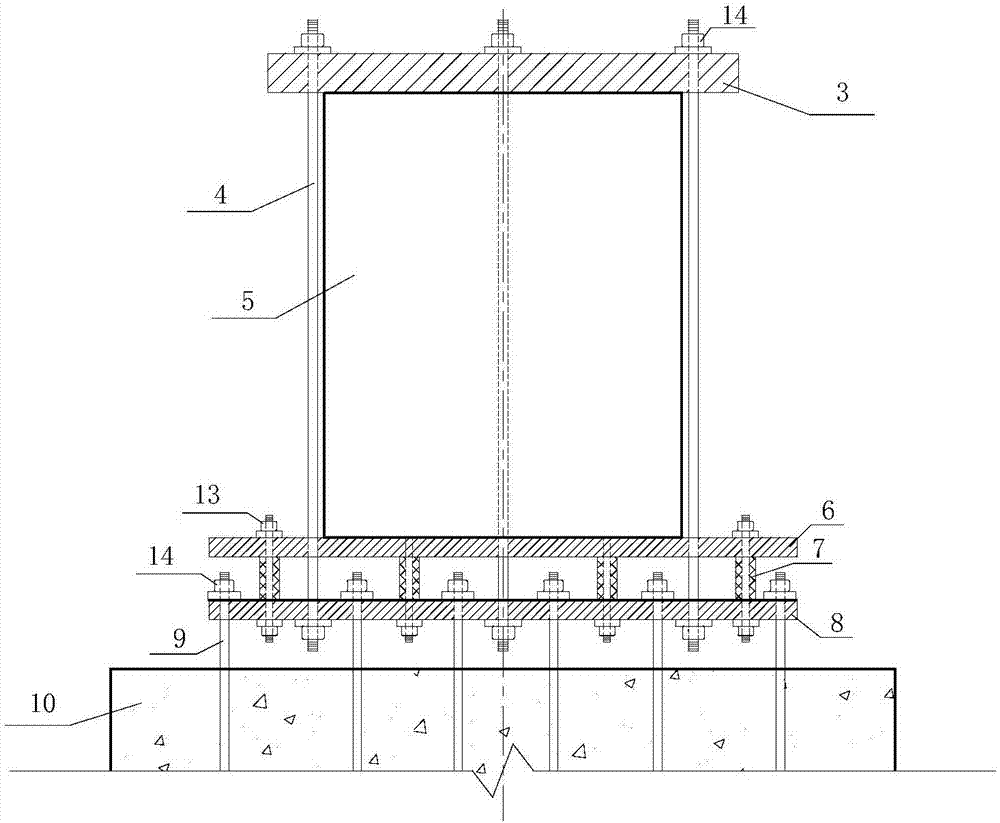

Foundation pile static load test system

A technology of static load test and foundation pile, which is applied in foundation structure test, foundation structure engineering, construction, etc. It can solve problems such as increased pile height, low test load, and broken pile accidents, so as to avoid pile head damage and The effects of broken pile accidents, reduced engineering costs, and reliable installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0050] The static load test of a certain foundation pile requires the bearing capacity of the foundation pile to reach 20000kN, among which the load Q of the surcharge load is 7000kN, the effective length l of the surcharge distribution is 10m, the distribution width B is 6.5m, and the uplift force P borne by the anchor pile is 13000kN . The secondary beam of the stacking platform is Q235B hot-rolled I-beam, the specification is 1560×166×12.5×21-12000mm, and the elastic modulus is E 1 200GPa, section moment of inertia I 1 6.56×10 4 cm 4 , the number k of secondary beams is 34, and the uniformly distributed load q of a single secondary beam under the action of 1.6Q is 32.9kN / m. The main girder of the test is a box girder made of Q345 material, and the elastic modulus E 2 200GPa, section moment of inertia I 2 3.2×10 6 cm 4 , a total of two main beams are arranged in parallel. The anchor bar is high-strength rebar, the diameter d is 50mm, and the modulus of elasticity is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com