Surface strengthened substrate preparation and performance calibration method

A surface enhancement and substrate technology, applied in the field of surface enhancement substrate preparation and calibration performance, can solve the problems of high cost, poor repeatability, complicated preparation process, etc., and achieve the effect of low cost, high repeatability and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

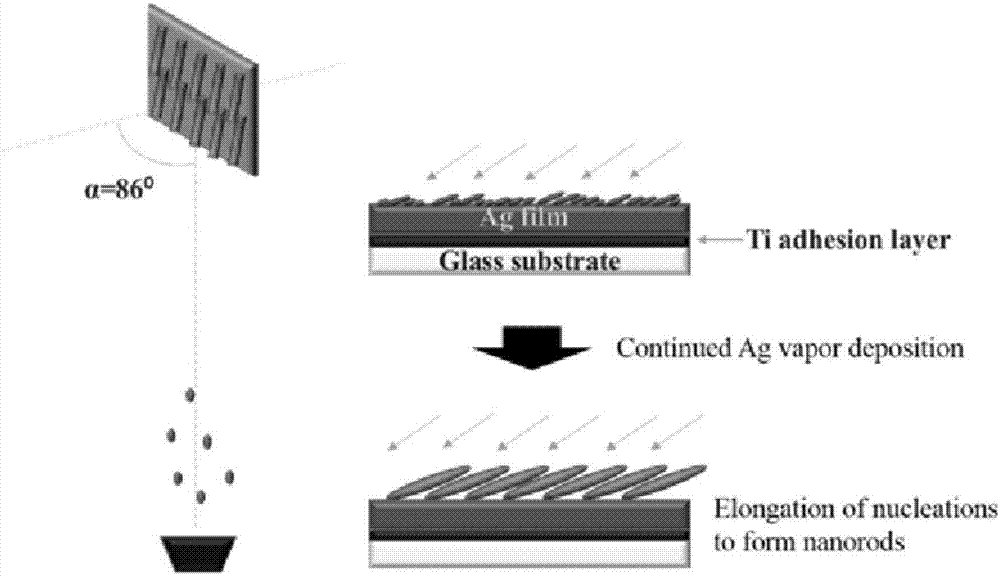

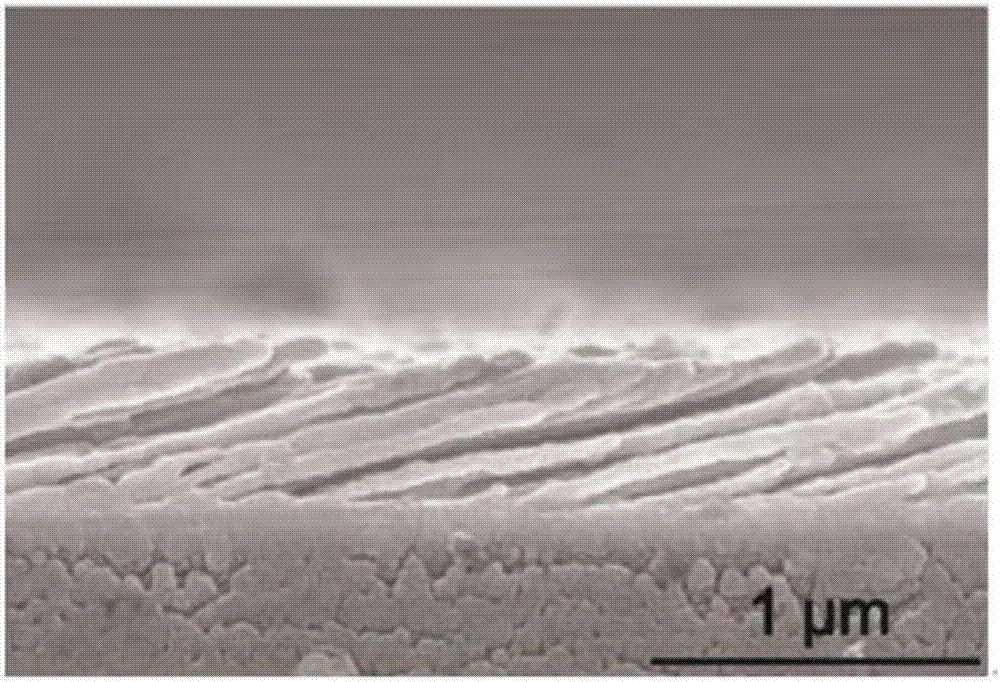

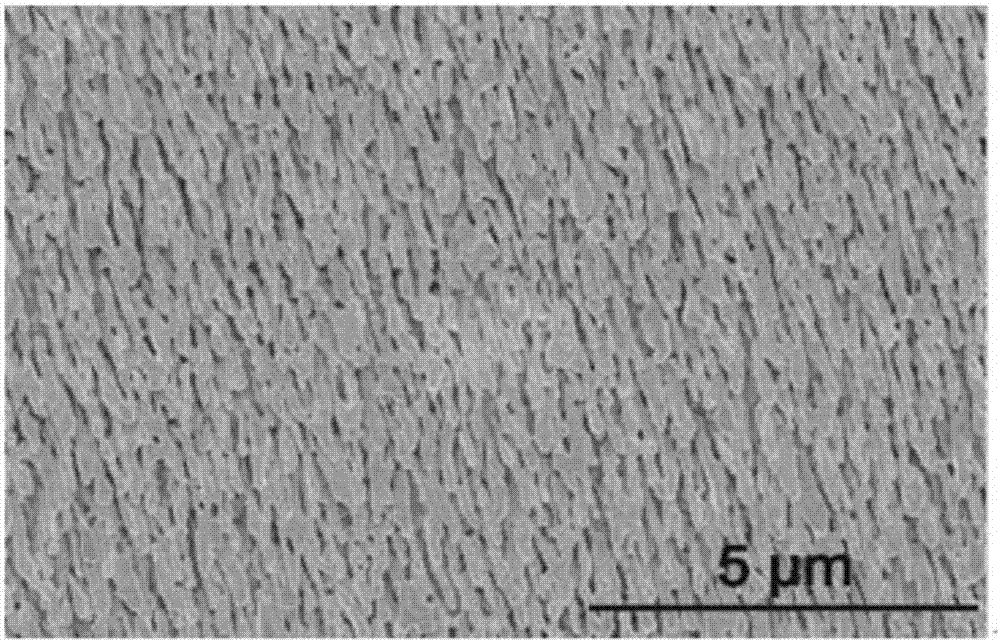

[0021] Example 1: This implementation provides a method for preparing and calibrating performance of a surface-enhanced substrate. Through dynamic shadow deposition technology, electron beam evaporation thin film deposition system is used to grow uniformly on a clean glass sheet under high vacuum conditions. An array of silver nanorods arranged obliquely, specifically comprising the following steps:

[0022] (1) Cut the glass piece into a square with a size of 1×1 cm2, soak it in the mixed washing solution and boil for 20 minutes, take it out, rinse it with secondary deionized water three times, dry it with nitrogen, and put it into the deposition chamber;

[0023] (2) Confirm whether the volume of the evaporation material silver and titanium in the crucible accounts for 70% of the crucible volume, confirm whether the life of the film thickness sensor is greater than 30%, check whether the cooling water circulation of the whole machine is normal, and whether the sample stage ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com