Preparation method of grapheme-nanometer precious metal composite pipe

A technology of graphene and precious metals, applied in the field of nanomaterials, can solve the problems of reducing the conductivity of graphene, and achieve the effects of simple operation, excellent mobility, and strong repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

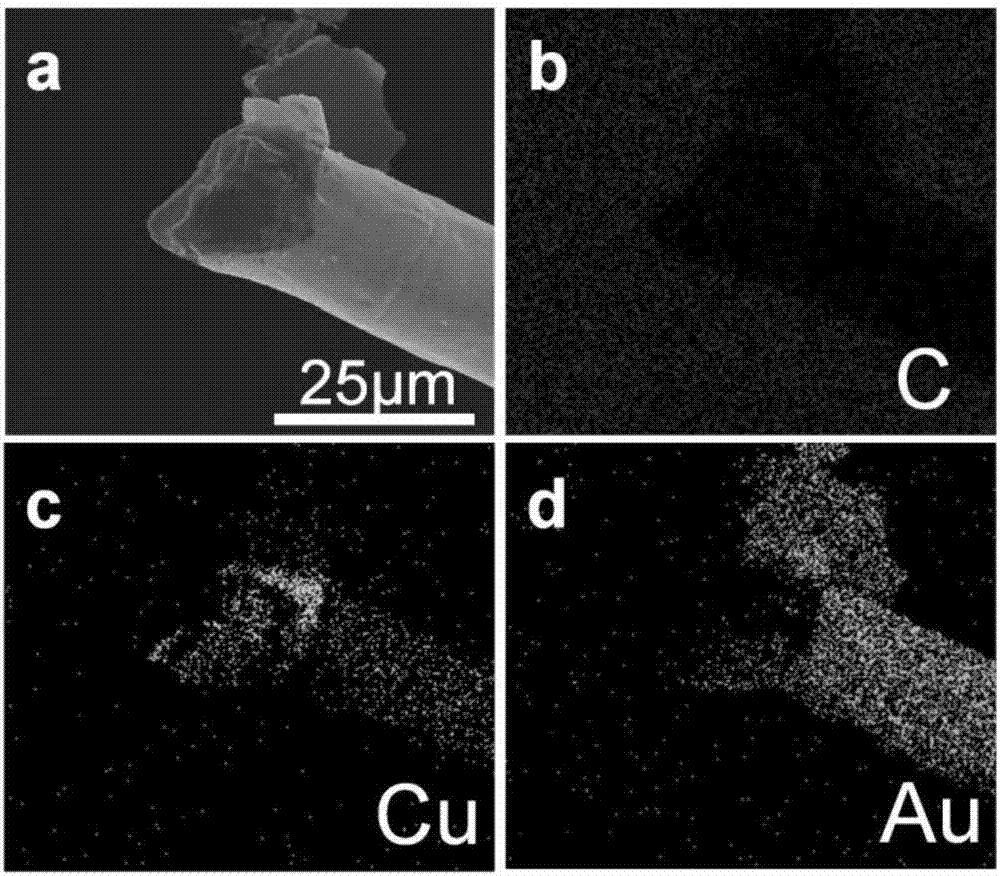

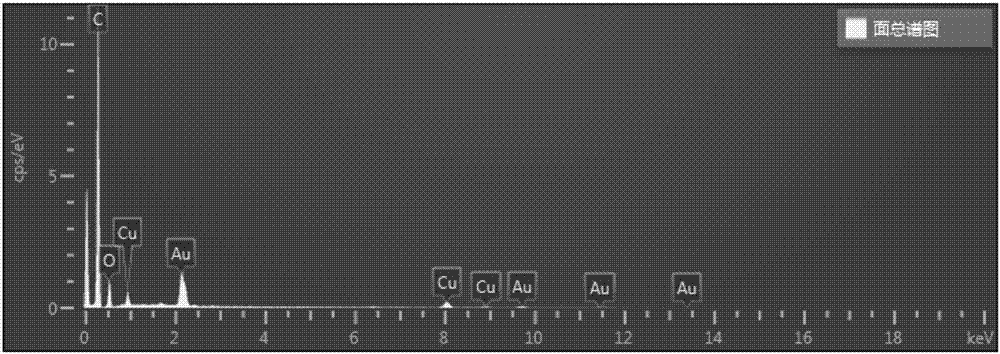

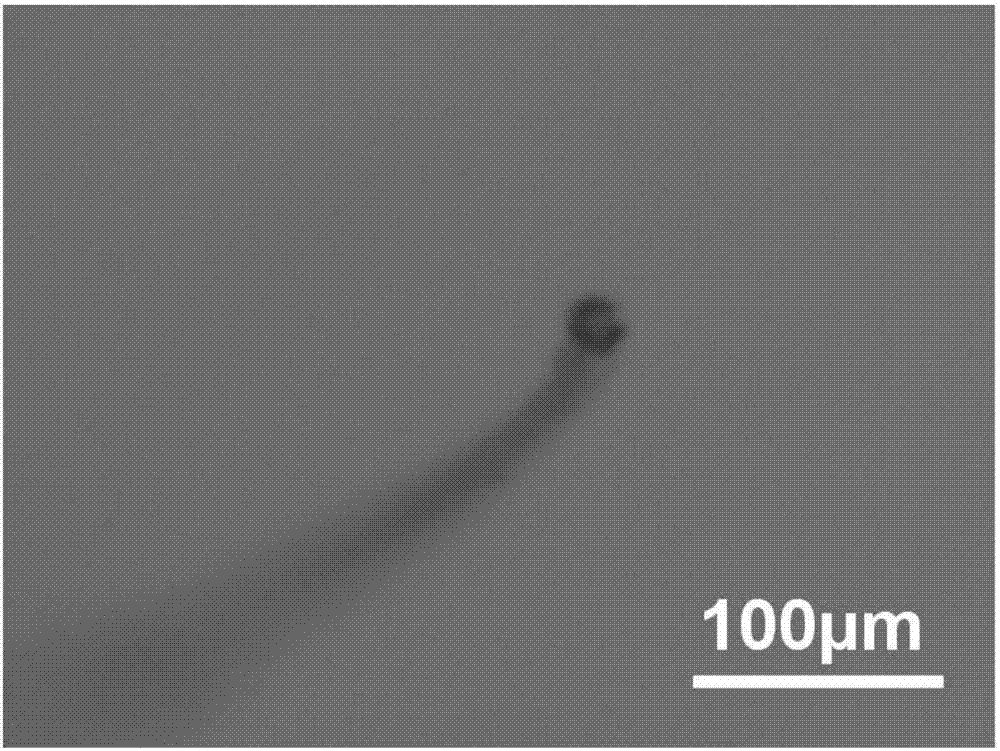

[0031] A preparation method of graphene-nano noble metal composite tube, comprising the following steps:

[0032] Step 1: Take a copper wire with a diameter of 15 μm and a length of 5 cm and soak it in 0.1 mol / L dilute nitric acid for 2 minutes to remove surface impurities and passivation layer, then place it in anhydrous ethanol for 20 minutes, and then place it in a blast drying oven at 60°C Dry for 2 hours and dry for later use;

[0033] Step 2. Put the dried copper wire as the growth substrate into the chemical vapor deposition equipment. The reaction atmosphere is a mixture of hydrogen and nitrogen. At a heating rate of 30°C / min, heat to 1000°C and keep the temperature constant for 60 minutes. Enter ethanol vapor 10sccm to react, stop feeding ethanol vapor after the reaction finishes, cool to room temperature rapidly, obtain graphene / copper wire composite structure;

[0034] Step 3, by magnetron sputtering, under the condition that the deposition rate is 20nm / s, a nano-g...

Embodiment 2

[0037] A preparation method of graphene-nano noble metal composite tube, comprising the following steps:

[0038] Step 1. Take a nickel wire with a diameter of 15 μm and a length of 5 cm and soak it in 0.1 mol / L dilute nitric acid for 2 minutes to remove surface impurities and passivation layer, then place it in anhydrous ethanol for 20 minutes, and then place it in a blast drying oven at 60°C Dry for 2 hours and dry for later use;

[0039] Step 2. Put the dried nickel wire as the growth substrate into the chemical vapor deposition equipment. The reaction atmosphere is a mixture of hydrogen and nitrogen. At a heating rate of 30°C / min, heat to 1000°C and keep the temperature constant for 60 minutes. Enter ethanol vapor 10sccm to react, stop feeding ethanol vapor after the reaction finishes, rapidly cool to room temperature, obtain graphene / nickel wire composite structure;

[0040] Step 3, by magnetron sputtering, under the condition that the deposition rate is 20nm / s, deposit ...

Embodiment 3

[0043] A kind of preparation method of graphene-nano noble metal composite tube is characterized in that, comprises the following steps:

[0044] Step 1: Take a copper wire with a diameter of 15 μm and a length of 5 cm and soak it in 0.1 mol / L dilute nitric acid for 2 minutes to remove surface impurities and passivation layer, then place it in anhydrous ethanol for 20 minutes, and then place it in a blast drying oven at 60°C Dry for 2 hours and dry for later use;

[0045] Step 2. Put the dried copper wire as the growth substrate into the chemical vapor deposition equipment. The reaction atmosphere is a mixture of hydrogen and nitrogen. At a heating rate of 20°C / min, heat to 1050°C and keep the temperature constant for 30 minutes. Enter ethanol vapor 20sccm to react, stop feeding ethanol vapor after the reaction finishes, cool to room temperature rapidly, obtain graphene / copper wire composite structure;

[0046] Step 3, by magnetron sputtering, under the condition that the dep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com