600 MPa-level high-strength low-alloy cold-strip steel and production method thereof

A high-strength low-alloy, cold-rolled strip technology, applied in the field of metallurgical plate production, can solve the problems of high precious metal alloy content, inability to industrialize production, unfavorable stable production, etc., achieve low yield ratio, increase plasticity, and reduce production effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10

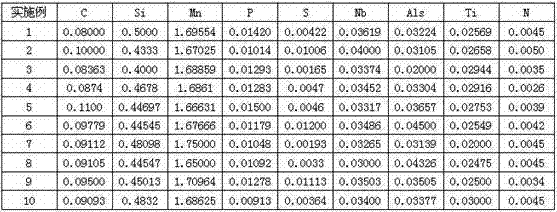

[0020] Embodiment 1~10 A kind of production method of 600MPa level high-strength low-alloy cold-rolled steel strip, comprises converter smelting, refining, continuous casting, hot rolling, cold rolling continuous annealing and smoothing process;

[0021] 1. The heating temperature for hot rolling is 1230-1270°C, the finish rolling temperature is 876-904°C, and the coiling temperature is 633-667°C; Process parameters:

[0022] Table 2 Hot rolling process parameters

[0023]

[0024] The hot rolling process has a higher coiling temperature to ensure sufficient precipitation and coarsening of microalloy carbonitride precipitates to achieve the purpose of reducing strength, which is conducive to reducing the strength of hot-rolled products, reducing the load of cold-rolling mills, and controlling the shape of cold-rolled strips. , Improve the quality of cold-rolled products.

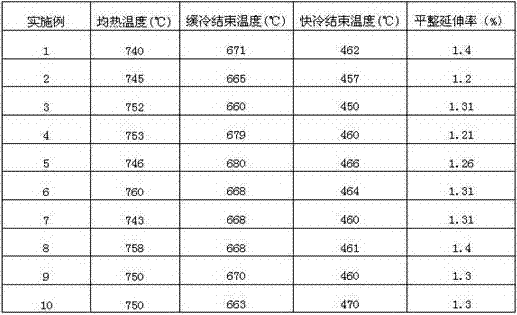

[0025] 2. In the continuous annealing and tempering process of cold rolling, the continuous annealin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com