Pseudomonas nitroreducens as well as fermentation product and application thereof

A technology of Pseudomonas and fermentation products, applied in the field of Pseudomonas nitroreductor and its fermentation products and in the field of cellulose degradation, can solve the problems of severe reaction conditions, long decomposition and transformation cycle, polluted air, etc., to achieve Efficient degradation and high enzyme activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) Inoculate the strain GM (that is, the nitroreductor pseudomonas with the preservation number of CGMCC No.13412) onto a GU-PDA plate (glucose: 20 g, potato powder 3 g, potassium dihydrogen phosphate: 3 g, magnesium sulfate: 1.5g, agar: 15g, guaiacol: 1g), in 30 ℃ in constant temperature incubator and cultivate 7d, reddish-brown discoloration circle appears around the bacterium colony, measure the diameter of 7mm and the diameter of discoloration circle ( H) is 13 mm, and the ratio (H / D) is 1.86, indicating that the bacterial strain of the present invention has better ligninase activity.

[0041] (2) Cultivate the strain GM (based on dry weight, the inoculum size is 25mg / L) in a constant temperature (30°C) shaker (170rpm) for 4 days, and the composition of the medium (1L) used is: CMC-Na 10g, KH 2 PO 4 4g, MgSO 4 ·7H 2 O 0.3g, peptone 3g, yeast powder 0.5g, (NH 4 ) 2 SO 4 2g, CaCl 2 2H 2 O 0.3g, Tween-80 0.2g, pH 6.5-7; the obtained culture was centrifuged at...

Embodiment 2

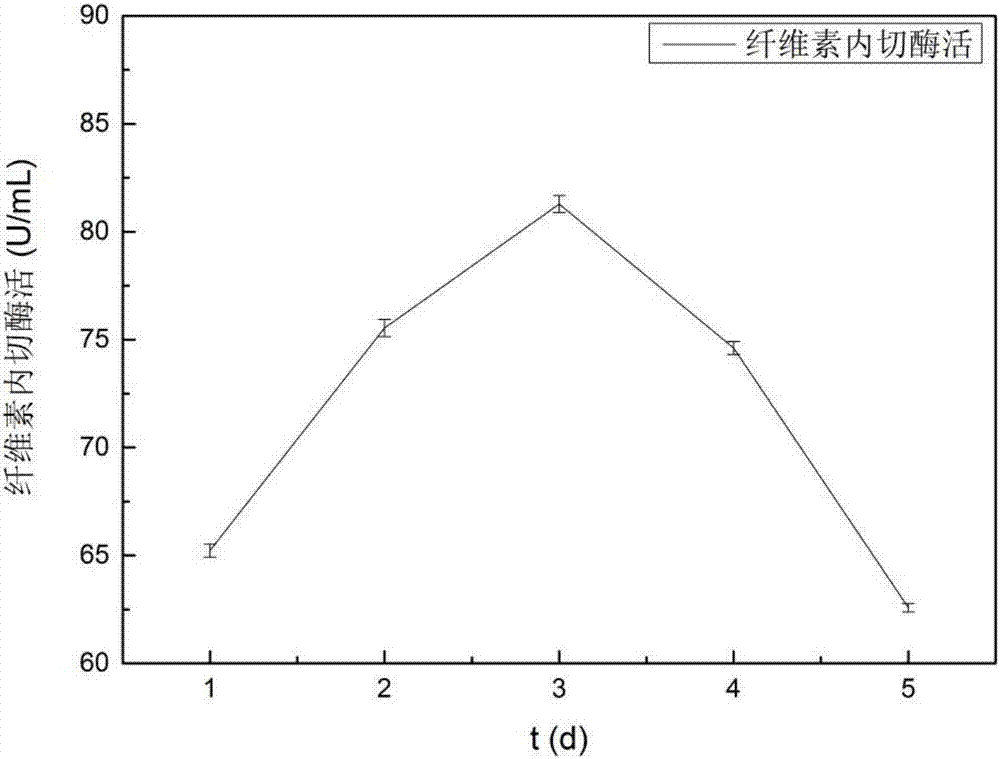

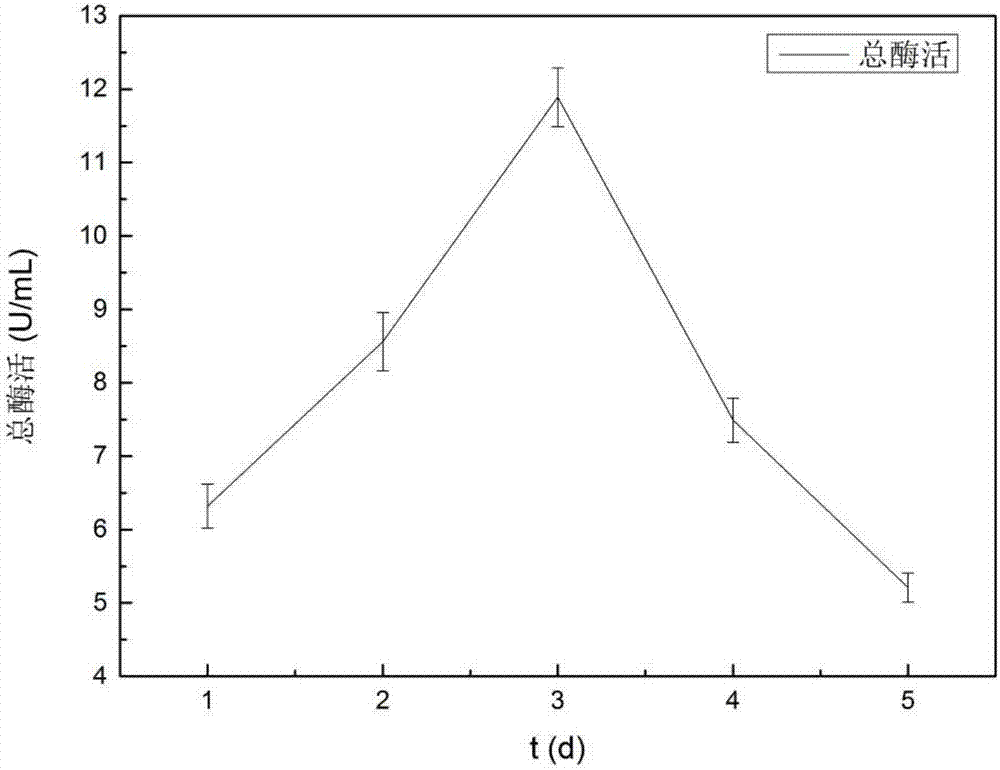

[0043] (1) Cultivate bacterial strain GM according to embodiment 1 step (2), the difference is that every 24h is sampled and measured for cellulosic endoenzyme activity and total enzyme activity (that is, filter paper enzyme activity), and making time is the abscissa, Enzyme activity curve with enzyme activity as the coordinate. The relationship between the enzyme activity and the culture time was obtained, and the results were as follows: figure 1 and figure 2 As shown, it can be seen that under liquid culture conditions, the activities of the two enzymes both reached the maximum on the third day, which were 82.35U / ml and 11.87U / ml respectively.

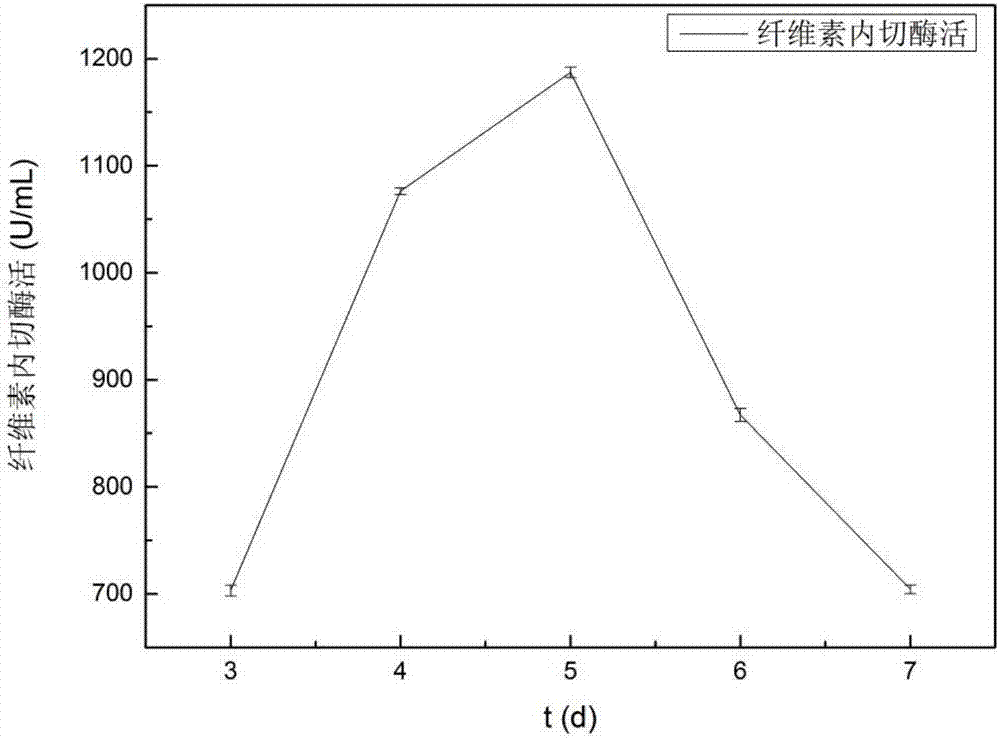

[0044] (2) Cultivate strain GM (based on dry weight, the inoculum size is 25 mg / L) at constant temperature (30°C), and the medium composition used is: 50 g of wheat straw (about 2 mm, taken from Baoding, Hebei), phosphoric acid Potassium dihydrogen 1g, magnesium sulfate heptahydrate 0.025g, ammonium sulfate 1g, deionized water 10...

Embodiment 3

[0046] Dry the 50ml Erlenmeyer flask and the ground wheat straw (about 2mm, taken from Baoding, Hebei) at high temperature and weigh it to the nearest 0.1mg, and record it as W 1 (conical flask) and W 2 (wheat straw). Weigh 1g of wheat straw, 7.5g of inorganic salt solution containing 0.5% by weight of yeast powder (containing 5mg dipotassium hydrogen phosphate, 5mg potassium dihydrogenphosphate, 1mg magnesium sulfate heptahydrate and 5mg ammonium sulfate), and put it into a 50ml Erlenmeyer flask Sterilize at 121°C for 15 minutes. Add 1 ml of strain GM inoculum (2.5 mg based on Pseudomonas nitroreducens), put it in a constant temperature incubator, and incubate at 30°C for 10 days. The strains were used as a parallel control group, and the results were averaged. Sterilized at 121°C for 15 minutes, dried and weighed, recorded as W 3 (total weight of Erlenmeyer flask and culture). According to "degradation rate = (W 1 +W 2 -W 3 ) / W 2 ×100%" to calculate the degradation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com