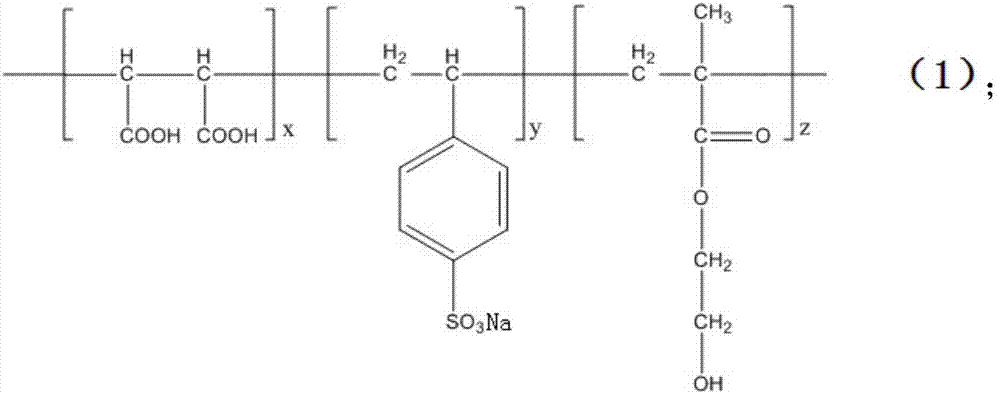

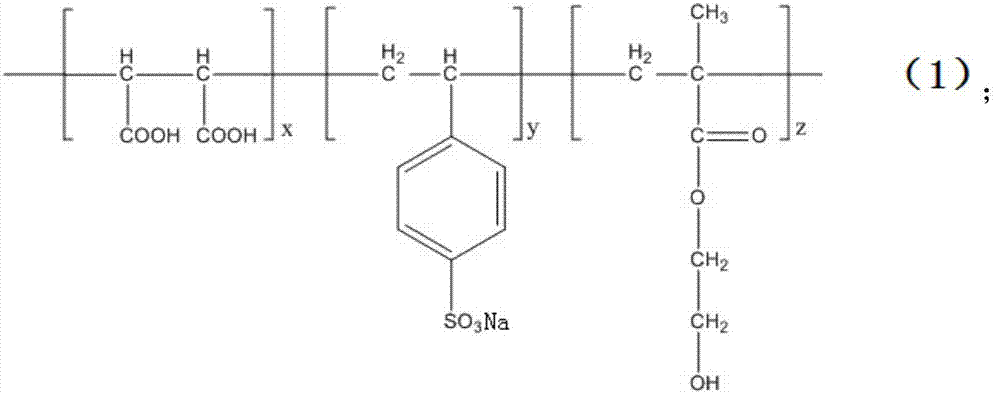

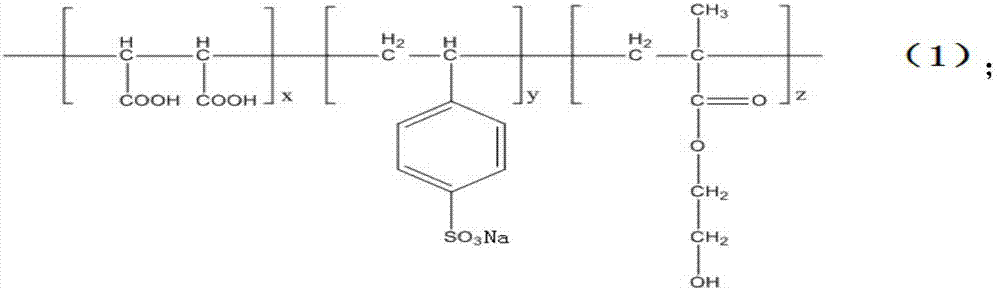

Scale inhibitor for sewage treatment, and preparation method thereof

A technology for sewage treatment and scale inhibitor, which is applied in water/sludge/sewage treatment, chemical instruments and methods, descaling and water softening, etc. Enterprise production costs and other issues, to achieve the effect of good inhibition ability, good scale inhibition effect, and lower operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of the above-mentioned scale inhibitor for sewage treatment is specifically implemented according to the following steps:

[0032] Step 1, get the following raw materials respectively by mass percentage:

[0033] Maleic anhydride 2.75% to 5.34%, sodium p-styrene sulfonate 1.86% to 1.93%, hydroxyethyl methacrylate 0.94% to 1.21%, initiator 0.45% to 0.82%, molecular regulator 0.45% to 0.82%, Distilled water 90.11% ~ 93.45%, the total content of the above raw materials is 100%;

[0034] Wherein, what initiator adopts is ammonium persulfate or other peroxides; Molecular regulator is tert-butanol;

[0035] Step 2, fix the three-neck flask, constant pressure dropping funnel and reflux condenser on the constant temperature heating magnetic stirrer, then add the maleic anhydride, sodium p-styrenesulfonate and hydroxyethyl methacrylate weighed in step 1 , Molecular regulator and distilled water are added in the three-necked flask, stirred and heated unti...

Embodiment 1

[0047] Step 1. Weigh respectively: 17.7608g of maleic anhydride, 6.1857g of sodium p-styrenesulfonate, 3.1234g of hydroxyethyl methacrylate, 2.707g of ammonium persulfate, 2.707g of tert-butanol, and 300g of distilled water;

[0048] Step 2, fix the three-neck flask, constant pressure dropping funnel and reflux condenser on the constant temperature heating magnetic stirrer, then add the maleic anhydride, sodium p-styrene sulfonate and hydroxyethyl methacrylate weighed in step 1 , tert-butanol and distilled water were added into a three-necked flask for stirring and heated to 85°C until all the solids in the three-necked flask were dissolved to obtain a mixed solution a;

[0049] Step 3. Add the initiator weighed in step 1 dropwise to the mixed solution a obtained in step 2 using a constant pressure dropping funnel. After the dropwise addition, carry out heat preservation treatment for 2.5 hours. After the reaction is completed, cool to room temperature, and then Adjust the pH ...

Embodiment 2

[0054] Step 1. Weigh respectively: maleic anhydride 8.8254g, sodium p-styrenesulfonate 6.1857g, hydroxyethyl methacrylate 3.1234g, ammonium persulfate 1.4508g, tert-butanol 1.4508g, distilled water 300g;

[0055] Step 2, fix the three-neck flask, constant pressure dropping funnel and reflux condenser on the constant temperature heating magnetic stirrer, then add the maleic anhydride, sodium p-styrenesulfonate and hydroxyethyl methacrylate weighed in step 1 , tert-butanol and distilled water were added to a three-necked flask for stirring and heated to 80°C until all the solids in the three-necked flask were dissolved to obtain a mixed solution a;

[0056] Step 3. Add the initiator weighed in step 1 dropwise to the mixed solution a obtained in step 2 using a constant pressure dropping funnel. After the dropwise addition, carry out heat preservation treatment for 3 hours. After the reaction is completed, cool to room temperature, and then use Sodium hydroxide solution adjusts th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com