IGBT device and preparation method thereof

A device and semiconductor technology, applied in the field of power semiconductor devices, can solve problems such as breakdown voltage reduction, cell damage, and easy failure, so as to achieve stable breakdown characteristics and improve avalanche tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

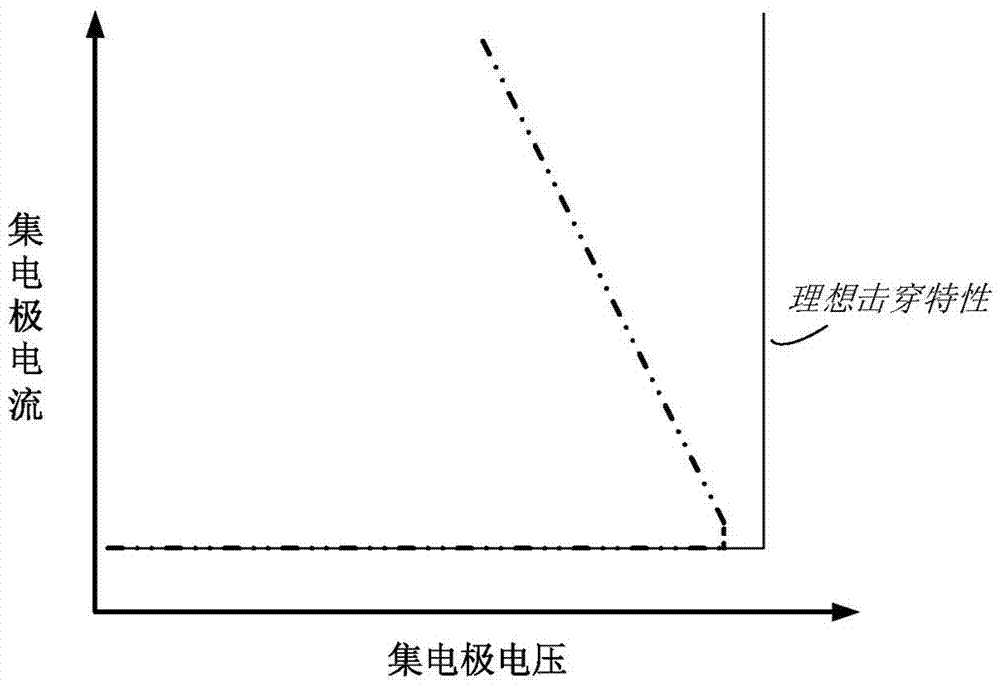

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Figure 4 Shown in is a schematic diagram of the cross-sectional structure of the IGBT device 300 according to the first embodiment of the present invention. The structure of the device 300 includes: a collector (122) (C pole) is located at the bottom of the device, and a p-type collector layer (106) (ie, the first semiconductor layer of the first conductivity type) is located between the collector (122) on; an n-type buffer layer (105) (that is, the second semiconductor layer of the second conductivity type) is located on the p-type collector layer (106); an n - type drift region (101) (that is, the third semiconductor region of the second conductivity type) is located on the n-type buffer layer (105); one or more parts are partially covered by the n-type - The trenches with different structural characteristics closed by the upper surface of the type drift region (101): the trenches include gate trenches (110) with a deep trench depth (that is, the first type of trenc...

Embodiment 2

[0034] Figure 17 Shown in is a schematic diagram of the cross-sectional structure of the IGBT device 400 according to the second embodiment of the present invention. It should be pointed out that in Figure 17 structure shown, with the above Figure 4 The same or equivalent structures shown in are given the same symbols, and descriptions of these symbols may not be repeated here. Similar to the device 300 described in the first embodiment, a feature of the device 400 is that it has a series of trenches with different structural features, including a deeper gate trench (110) and a shallower dummy trench (210), to Improve the avalanche tolerance and reliability of the device. However, device 400 also has another characteristic, that is, the lateral spacing between adjacent gate grooves (110) (not in Figure 17 shown in ), and the lateral spacing between the gate groove (110) and the adjacent dummy groove (210) ( Figure 17 marked as "m") are greater than the lateral spacin...

Embodiment 3

[0036] Figure 18 Shown in is a schematic diagram of the cross-sectional structure of the IGBT device 500 according to the third embodiment of the present invention. It should be pointed out that in Figure 18 structure shown, with the above Figure 4 to Figure 17 The same or equivalent structures shown in are given the same symbols, and descriptions of these symbols may not be repeated here. Similar to the device 300 described in the first embodiment, a feature of the device 500 is that it has a series of trenches with different structural features, including a deeper gate trench (110) and a shallower dummy trench (210), to Improve the avalanche tolerance and reliability of the device. However, the device 500 also has another characteristic, that is, no electrically floating p-region ( 202 ) is set between adjacent dummy slots ( 210 ). Since the electrically floating p-region ( 202 ) cannot effectively support the voltage when the device is turned off, removing this regio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com