Intelligent remote-control self-power electrochromic window and method for preparing same

An electrochromic, intelligent remote control technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of reducing electrochromic properties, reducing device transmittance, low photoelectric conversion efficiency, etc., to reduce the degree of use and comfort. Working and living environment, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

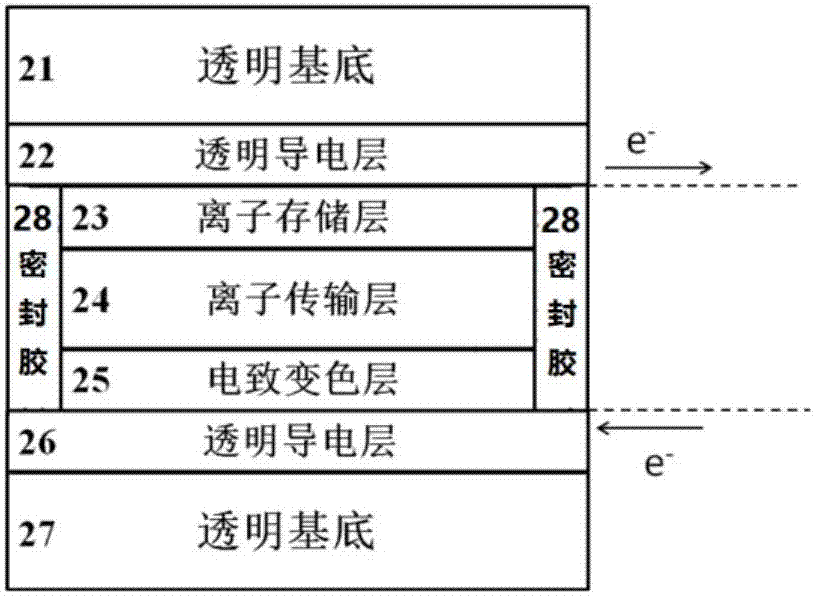

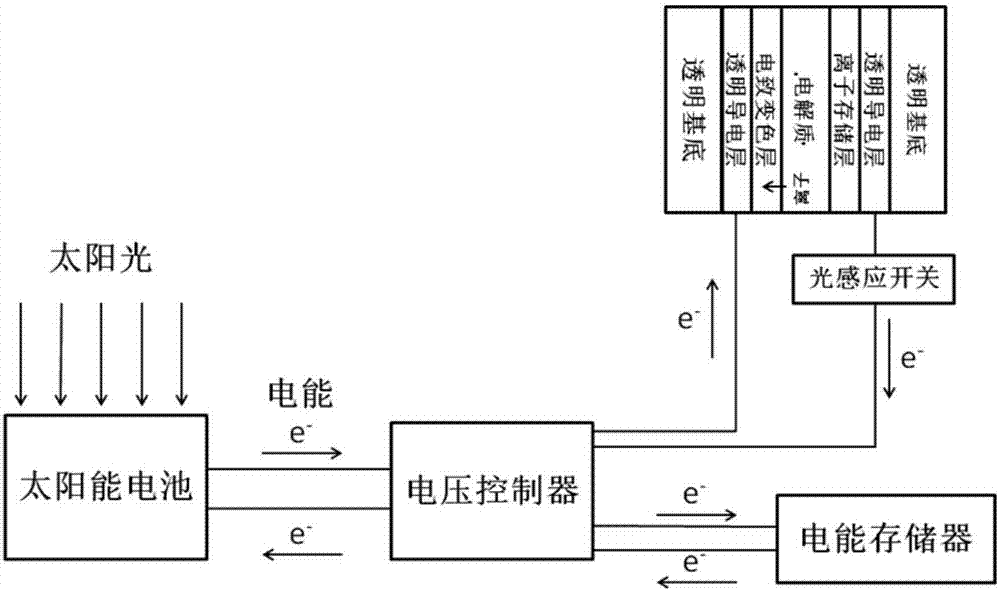

[0033] A method for preparing an electrochromic device for an intelligent remote-controlled self-powered electrochromic window, characterized in that the preparation steps are as follows:

[0034] 1. Using magnetron sputtering, chemical vapor deposition, spraying, pulling, electrodeposition or spin coating, the first transparent conductive layer 22, ion storage layer 23, ion Transport layer 24, electrochromic layer 25 and second transparent conductive layer 26;

[0035] 2. Lead out the electrodes on the first transparent conductive layer and the second transparent conductive layer, cover another transparent substrate 27 on the second electrochromic layer, and coat the sealant 28 around the two layers of transparent substrates for lamination and sealing Assemble.

[0036] The preparation method of an electrochromic device for an intelligent remote control self-powered electrochromic window is characterized in that the preparation steps are as follows:

[0037] 1. Prepare the ...

Embodiment 1

[0044] The composition of the device: the transparent conductive layer is an ITO film, the ion storage layer is a thin film NiO, and the electrolyte is made of LiClO 4 and propylene carbonate, the electrochromic layer is WO 3 film;

[0045] Device fabrication process:

[0046] Preparation of the counter electrode: The transparent conductive layer ITO and the ion storage layer NiO are sequentially deposited on the transparent substrate by magnetron sputtering. The thickness of the ITO film is 200nm, and the thickness of the NiO film is about 300nm;

[0047] Prepare the working electrode: use the magnetron sputtering method to sequentially deposit the transparent conductive layer ITO and the electrochromic layer as WO on another transparent substrate. 3 , ITO film thickness is 200nm, WO 3 The thickness of the film is about 300nm;

[0048] Device assembly: counter electrode and working electrode. The working electrode and the counter electrode are bonded together, and the liq...

Embodiment 2

[0052] The composition of the device: the transparent conductive layer is an ITO film, the ion storage layer is a thin film PB, and the electrolyte is made of LiClO 4 and propylene carbonate, the electrochromic layer is WO 3 film;

[0053] Device fabrication process:

[0054] Prepare the counter electrode: use the magnetron sputtering method and the electrodeposition method to deposit the transparent conductive layer ITO and the ion storage layer PB sequentially on the transparent substrate. The thickness of the ITO film is 200nm, and the thickness of the PB film is about 100nm;

[0055] Prepare the working electrode: use the magnetron sputtering method to sequentially deposit the transparent conductive layer ITO and the electrochromic layer as WO on another transparent substrate. 3 , ITO film thickness is 200nm, WO 3 The thickness of the film is about 300nm;

[0056] Device assembly: counter electrode and working electrode. The working electrode and the counter electrode ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com