Electrochromic film

An electrochromic film and electrode technology, applied in the field of color-changing films, can solve the problem that the local discoloration area cannot be accurately controlled, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

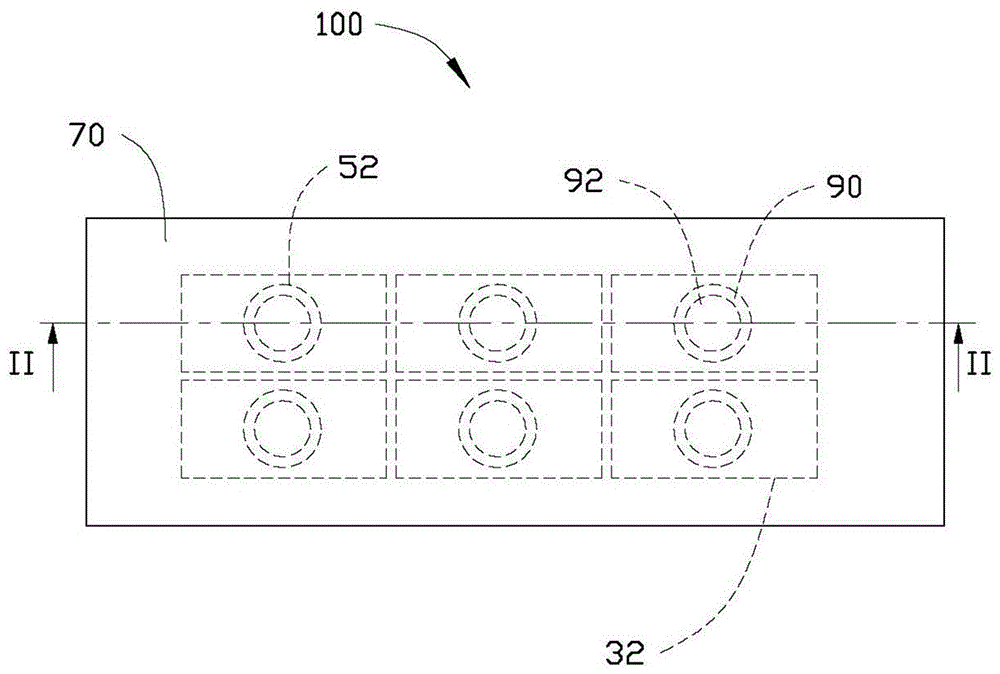

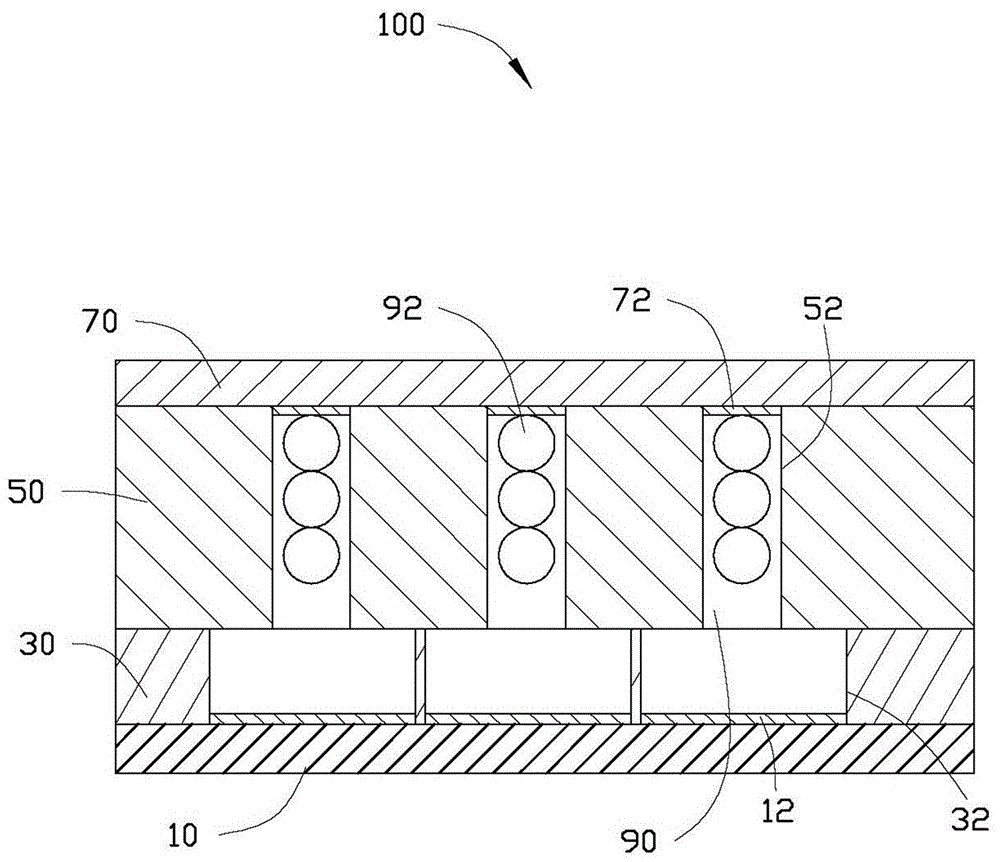

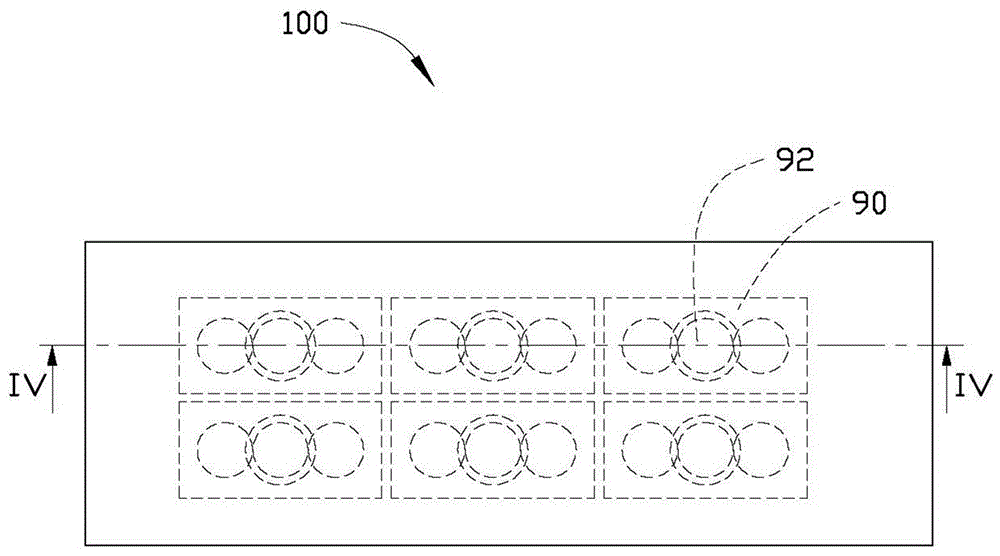

[0015] Please also refer to figure 1 and figure 2 , The electrochromic film 100 according to the embodiment of the present invention includes a first substrate 10 , a first film layer 30 , a second film layer 50 , a second substrate 70 and a dielectric solution 90 . The first substrate 10 , the first film layer 30 , the second film layer 50 and the second substrate 70 are all in the form of transparent films and stacked in sequence. The dielectric solution 90 is accommodated in the first film layer 30 and the second film layer 50 .

[0016] The first substrate 10 is a transparent film, and a plurality of first electrodes 12 arranged in a matrix are formed on one surface thereof. The first electrode 12 is a transparent electrode. In this embodiment, the first electrode 12 is an indium tin oxide (ITO) electrode, which is rectangular, and the first electrode 12 is adhered to the surface of the first substrate 10 by printing. Each first electrode 12 is electrically connected t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com