Underground mixed-phase thermal fluid generator and using method thereof

A technology of thermal fluid and generator, applied in the field of downhole miscible thermal fluid generator, can solve the problems of large environmental pollution, large heat loss, melting of gas hydration layer, etc., to reduce environmental pollution, reduce heat loss, and increase fluidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

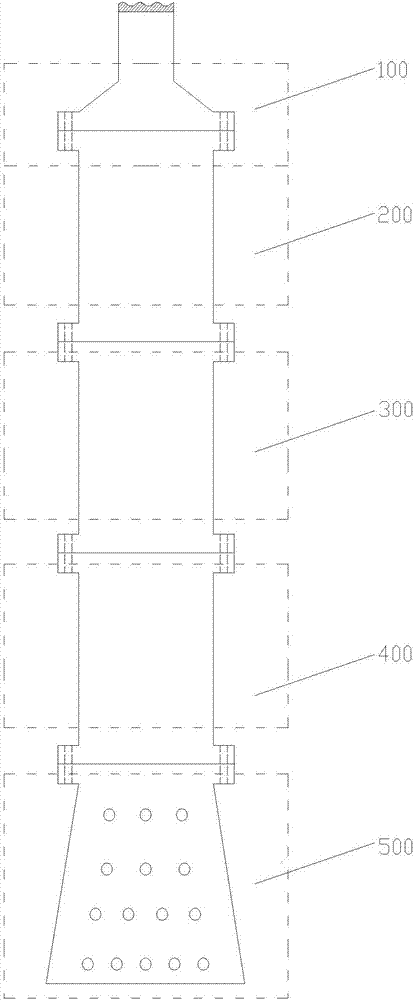

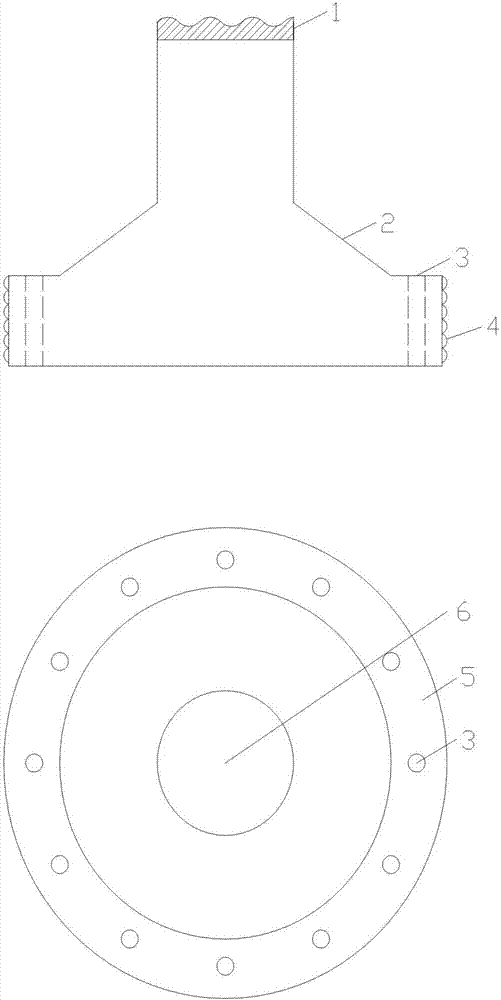

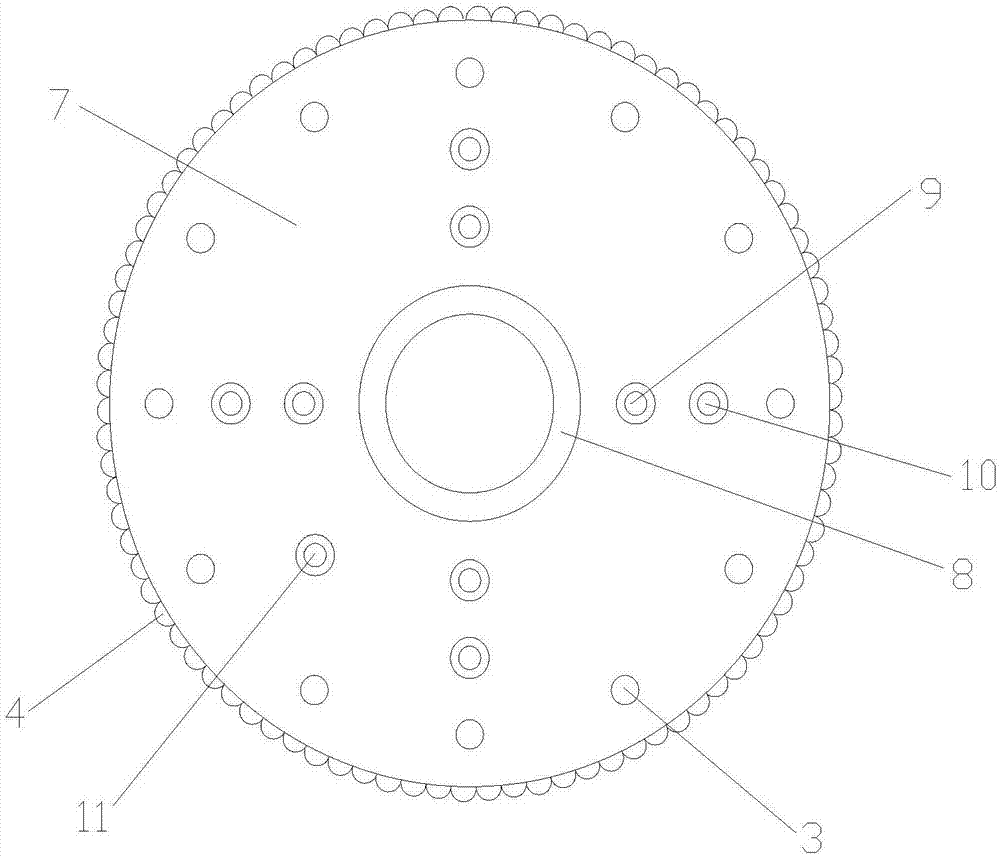

[0026] figure 1 It is a schematic diagram of the structure of the downhole miscible thermal fluid generator. The downhole mixed-phase thermal fluid generator includes a top connection assembly 100 , a combustion assembly 200 , a vaporization assembly 300 , a screw pressurization assembly 400 and an injection assembly 500 . The top connection assembly 100 is connected to the upper part of the combustion assembly 200 by bolts, the vaporization assembly 300 is connected to the lower part of the combustion assembly 200 by bolts, the screw booster assembly 400 is connected to the lower part of the vaporization assembly 300 by bolts, and the injection assembly 500 is connected to the screw booster assembly by bolts 400 lower part; the outer diameter of the connection of the top connection assembly 100, the combustion assembly 200, the vaporization assembly 300, the screw pressurization assembly 400 and the injection assembly 500 is defined by the inner diameter of the oil well casin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com