Graphene wear-resistant coating

A wear-resistant coating, graphene technology, applied in polyamide coatings, epoxy resin coatings, coatings, etc., to achieve good heat resistance and thermal conductivity, prevent chemical degradation, reduce friction coefficient and wear rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

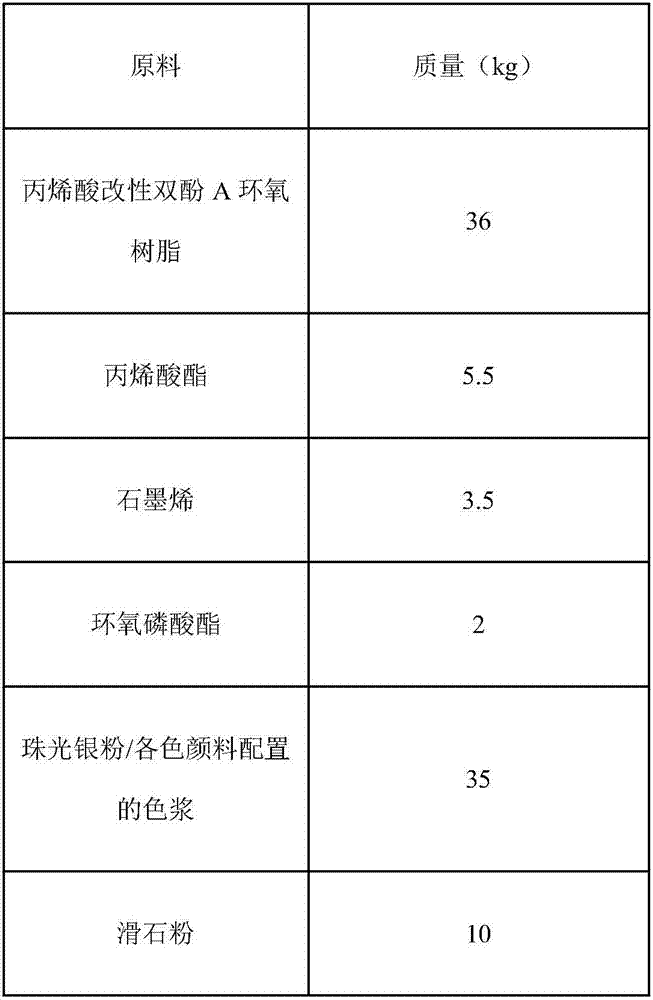

[0016] After weighing each raw material according to the proportioning ratio in Table 1, stir and mix at 1600-2000 rpm. The graphene wear-resistant coating can be obtained;

[0017] The raw material formula of table 1 graphene wear-resistant coating

[0018]

[0019]

Embodiment 2

[0021] Stir and mix after weighing each raw material by the proportioning of Table 2 to obtain the graphene wear-resistant coating;

[0022] The raw material formula of table 2 graphene wear-resistant coating

[0023]

[0024]

Embodiment 3

[0026] Stir and mix after weighing each raw material by the proportioning of Table 3 to obtain the graphene wear-resistant coating;

[0027] The raw material formula of table 3 graphene wear-resistant coating

[0028]

[0029]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com