Electrical equipment fault diagnosis method, temperature-sensitive paint and production method of paint

A heat-sensitive coating and electrical equipment technology, applied in heat-sensitive coatings, coatings, etc., can solve problems such as high local temperature, fire, equipment discharge, etc., achieve the effects of short discoloration time, long service life, and anti-aging and corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The heat-sensitive coating is prepared according to the following composition ratio:

[0024] Commercially available acrylic resin: 45.0%;

[0025] Thermochromic material: 25.0%;

[0027] Xylene: 20.0%

[0028] The heat-sensitive color-changing material adopts microcapsules of room temperature ionic liquid and crystal violet lactone, crystal violet lactone accounts for 65% of the total weight of the heat-sensitive color-changing material, and the rest is room temperature ionic liquid, which is prepared by microemulsion method.

[0029] The preparation method of this thermosensitive coating is:

[0030] a. Add the polyurethane resin of the above weight part and 2 / 3 of the xylene of the above weight part into the batching tank, heat to 50° C. and stir for 30 minutes, and the rotation speed is 400 r / min;

[0031] b. Add the above-mentioned heat-sensitive color-changing material in the state of stirring to the material mixed in step a, stir ...

Embodiment 2

[0035] The heat-sensitive coating is prepared according to the following composition ratio:

[0036] Commercially available silicone resin: 35.0%;

[0037] Heat-sensitive discoloration material: 30.0%;

[0038] Kaolin: 25.0%;

[0039] Toluene: 10.0%

[0040] The heat-sensitive color-changing material adopts microcapsules of room temperature ionic liquid and crystal violet lactone, crystal violet lactone accounts for 30% of the total weight of the heat-sensitive color-changing material, and the rest is room temperature ionic liquid, which is prepared by microemulsion method.

[0041] The preparation method of this thermosensitive coating is:

[0042] a. Add the silicone resin of the above weight portion and 2 / 3 of the toluene of the above weight portion into the batching tank, heat to 65°C and stir for 40min, and the rotating speed is 500r / min;

[0043] b. Add the above-mentioned heat-sensitive color-changing material by weight to the material mixed in step a while stirring...

Embodiment approach

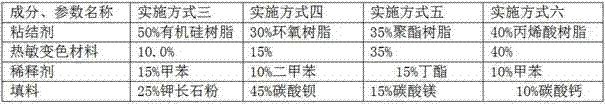

[0048]

[0049] The heat-sensitive color-changing material crystal violet lactone in Embodiment 3 accounts for 10% of the total weight of the heat-sensitive color-changing material, and the rest is room temperature ionic liquid.

[0050] For the third embodiment, the following operations will be performed:

[0051] a. Add the silicone resin of the above weight part and 2 / 3 of the toluene of the above weight part into the batching tank, heat to 75 ° C and stir for 20 minutes, and the speed is 600 rpm;

[0052] b. Add the above-mentioned heat-sensitive color-changing material by weight to the material mixed in step a while stirring, and stir for 30 minutes at a speed of 400 rpm to disperse and wet to obtain a pre-pulp;

[0053] c. Cool the pre-pulp in step b to 40°C, and grind it to a fineness of 10 microns with a ball mill to obtain a feed liquid;

[0054] d. Cool the material liquid in step c to 25°C, add the remaining toluene under stirring, continue stirring and mixing, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com