Electrochromic material and preparation method thereof, and anti-dazzling automobile rear-vision mirror

An electrochromic material, a technology for automotive rearview mirrors, applied in the direction of color-changing fluorescent materials, chemical instruments and methods, vehicle components, etc., can solve the problems of slow response time, image distortion, etc. Effect of color change time reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

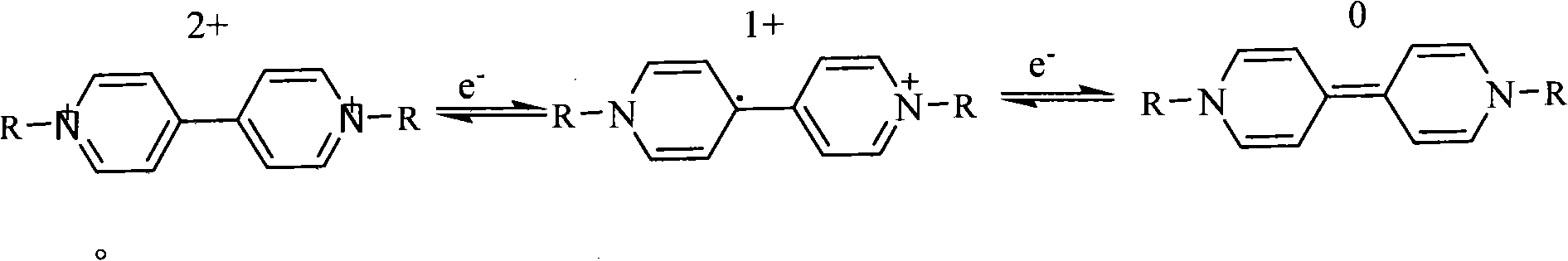

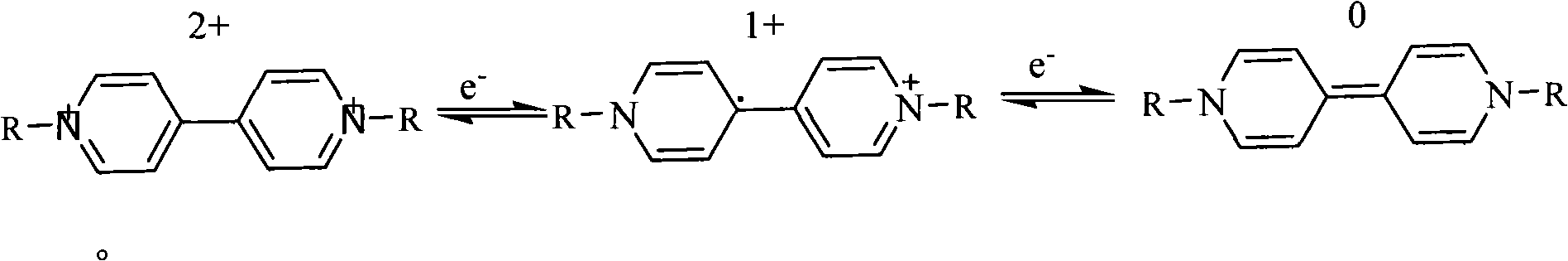

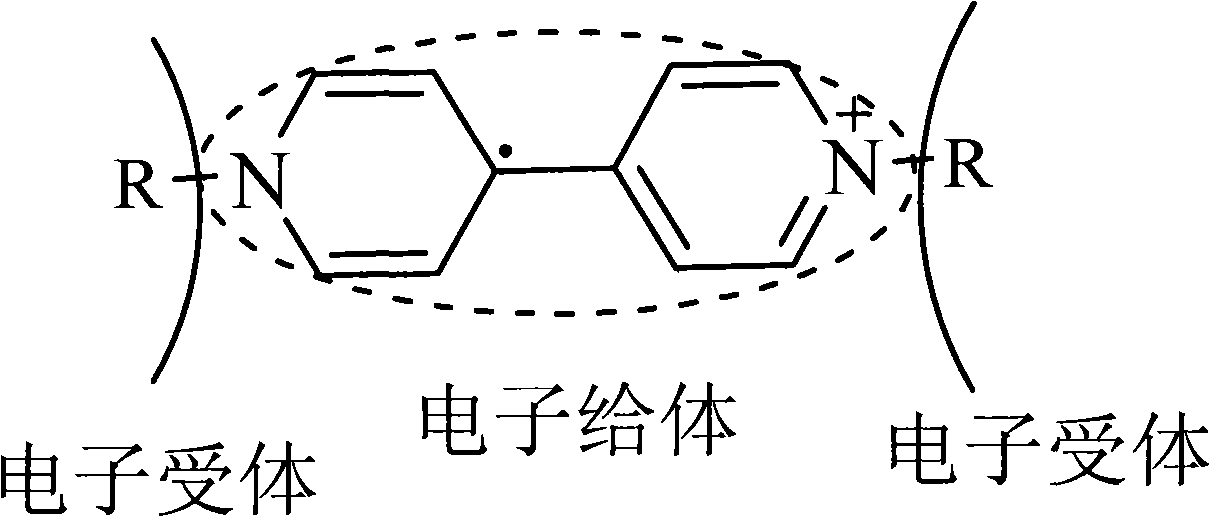

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1) Synthesize the electrochromic material of the present invention

[0034] Weigh 0.02mol of bipyridine and 0.03mol of 1,2,4,5-tetracyano-3-bromobenzene into a 250ml round-bottomed flask, add 50mL of acetonitrile at 90°C for 15h under reflux, a black precipitate is produced, wait After the reaction, the compound was washed with ethanol, filtered and dried in vacuum. Add 10 mL of the above product solution to deionized water into 100 mL of saturated LiClO 4 Stir in the aqueous solution to obtain purple-black solid particles, filter with suction, and dry in vacuum to obtain the electrochromic material A1 of the present invention.

[0035] 2) Assemble the rearview mirror

[0036]The electrochromic material A1 obtained in the above steps, and the phenothiazine according to the molar ratio of 1:1, add the solution to configure the electrochromic material in the electrochromic layer, the solution is propylene carbonate, the electrochromic material The concentration of A is...

Embodiment 2

[0038] The difference from Example 1 is that 0.02mol of bipyridine and 0.03mol of 1,7-dicyano-5-bromonaphthalene are added to a 250ml round bottom flask, and 50mL of DMF (N,N-dimethylformaldehyde Amide) was refluxed at 100° C. for 10 h to produce a black precipitate. After the reaction was complete, the compound was washed with acetonitrile, filtered and dried in vacuo. Add 10 mL of the above product solution to deionized water into 100 mL of saturated LiClO 4 Stir in the aqueous solution to obtain black solid particles, filter with suction, and dry in vacuum to obtain the electrochromic material A2 of the present invention.

[0039] A rearview mirror A22 is formed.

Embodiment 3

[0041] The difference from Example 1 is that 0.02mol of bipyridyl and 0.03mol of 2,6-dicyano-4-bromonaphthalene are added to a 250ml round bottom flask, and 50mL of DMF (N,N-dimethylformaldehyde Amide) was refluxed at 100° C. for 10 h to produce a black precipitate. After the reaction was complete, the compound was washed with acetonitrile, filtered and dried in vacuo. Add 10 mL of the above product solution to deionized water into 100 mL of saturated LiClO 4 Stir in the aqueous solution to obtain black solid particles, filter with suction, and dry in vacuum to obtain the electrochromic material A3 of the present invention.

[0042] Form the rear view mirror A33.

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com