Repeated stratifying, zoning-screening gravity concentration method

A screening and banding technology, applied in chemical instruments and methods, solid separation, wet separation, etc., can solve problems such as low recovery rate, poor gravity separation effect, low concentrate grade, etc., to achieve high recovery rate, Reduced potential energy difference and high concentrate grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The preferred embodiments of the present invention will be further described in detail below.

[0030] A lead-zinc mine, raw ore analysis results:

[0031] Galena 1.74%, sphalerite 6.46%, pyrite 14.67%, barite (barium sulfate) 26.01%, dolomite 43.48%, others (a small amount of quartz, barium-containing feldspar, muscovite, etc.) 7.64%. There are no less than 5 kinds of mineral components. The minerals for beneficiation are galena and sphalerite, and the secondary minerals are barite. The embedded particle size of galena and sphalerite is uneven, and the embedded particle size of galena is smaller than that of sphalerite. The proportion of fine particles smaller than 0.02mm in galena is 21.26%, and that of sphalerite is smaller than 0.02mm. The proportion of fine particles is 13.62%. This mineral is a typical multi-component mineral with fine grain size.

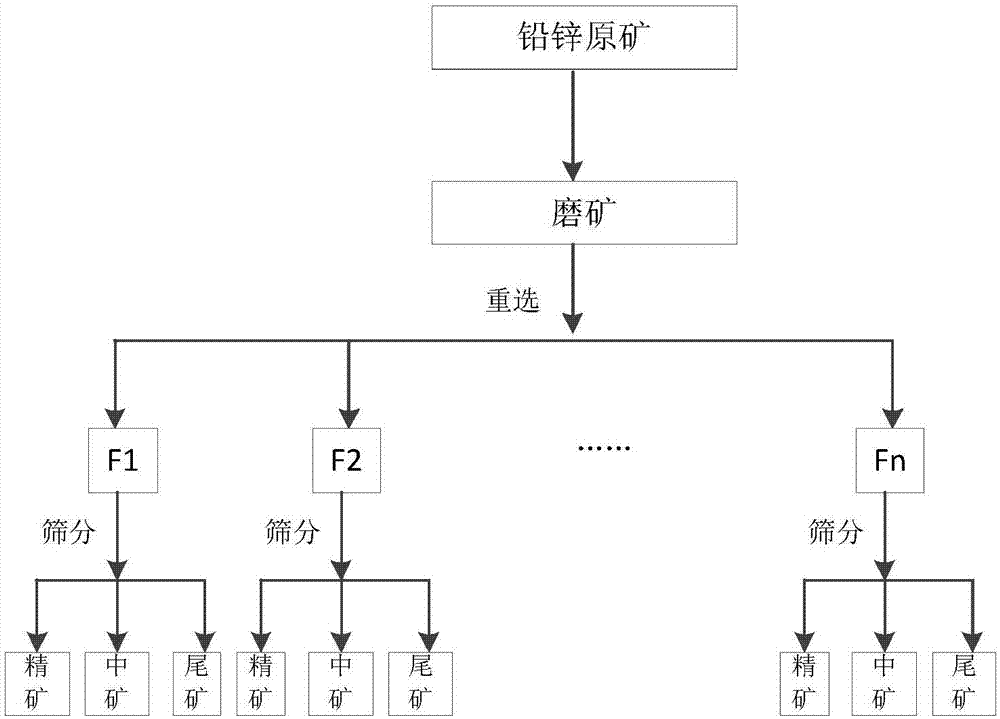

[0032] The beneficiation process is as figure 1 As shown, after the minerals are crushed and fully dissociated, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com