A universal board that can prevent welding penetration

A technology for anti-welding and board body, applied in the field of universal boards, can solve the problems of waste, copper strips, damage to the universal board, etc., and achieve the effects of low welding level requirements, simple welding operations, and beautiful welding effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solution of the present invention is further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the description.

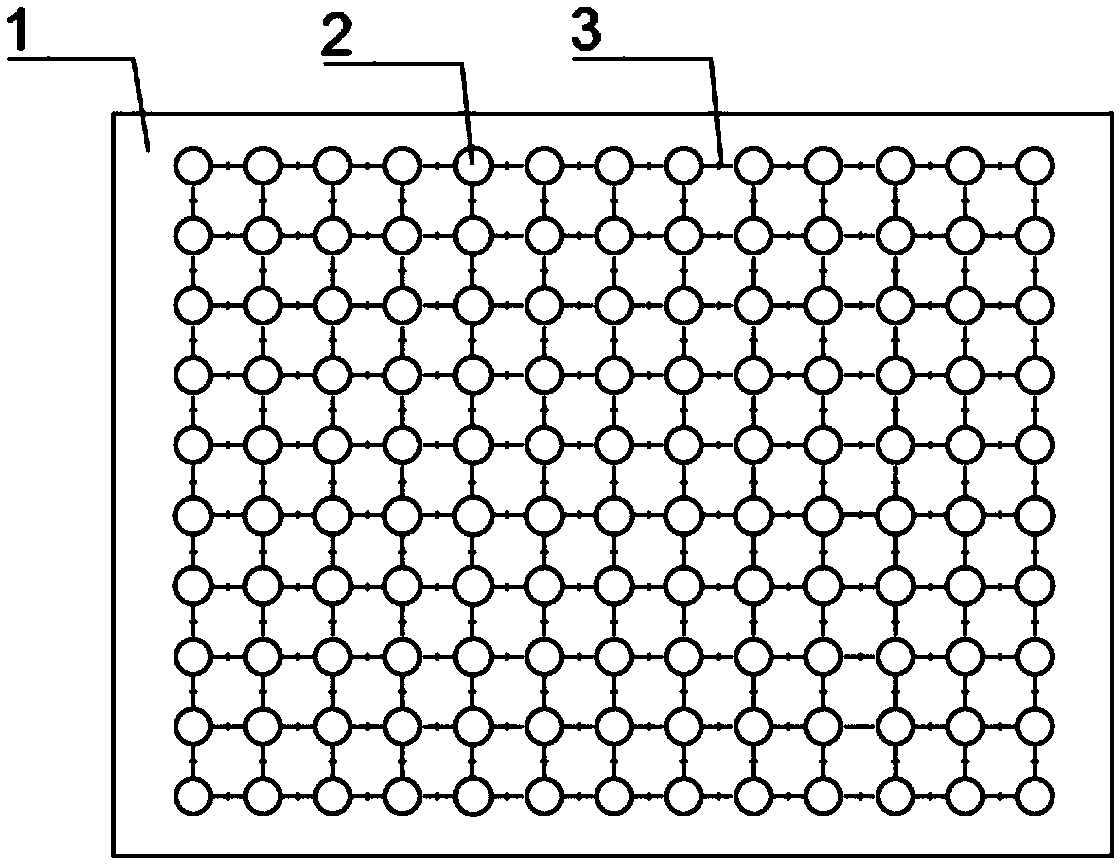

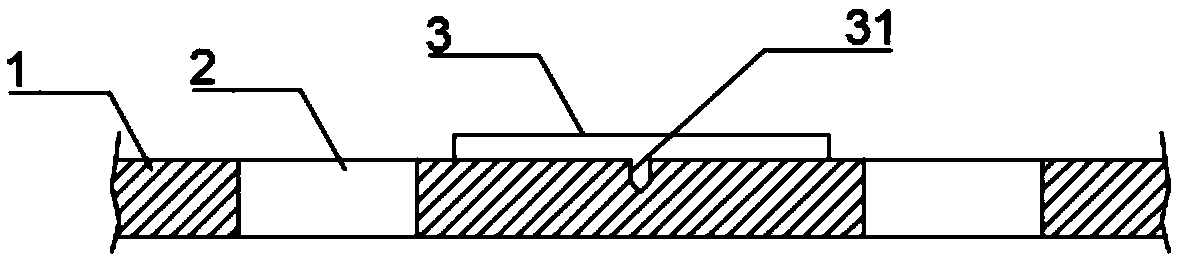

[0017] Such as figure 1 and figure 2 As shown, a universal board that can prevent welding penetration includes a universal board body 1 and jacks 2, the jacks 2 are arranged on the universal board body 1 in a matrix, and the horizontal and vertical jacks 2 The distance between them is equal, conductive material is provided on the socket 2, and copper wire 3 is also provided between the socket 2, and the copper wire 3 does not contact with the edge of the socket 2.

[0018] The universal plate body 1 is square, with a size of 10cm×150cm, or 90×150cm, a thickness of 1.6mm, and double-sided or single-sided green paint.

[0019] The jacks 2 of the present invention are arranged in a matrix on the universal board body 1 , and the conductive material provided on the jacks 2 is copper or ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com