Washhouse carrying equipment fault diagnosis method based on fault tree

A handling equipment and fault diagnosis technology, which is applied in the fault tree-based storage and handling equipment fault diagnosis field, can solve the problems of time-consuming and labor-intensive, difficult location of fault points, increased diagnosis costs, etc., and achieve the effect of solving high maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Such as figure 1 As shown, a fault tree-based fault diagnosis method for storage and handling equipment includes the following steps:

[0050] Stp1: Write a fault tree analysis program in MATLAB software, which includes a qualitative analysis module and a quantitative analysis module.

[0051] Stp2: Select the top event, select the fault top event and its code for the common faults that occur during the use of storage and handling equipment, top events include high pedal fault, pre-charging fault, overcurrent, controller overheating, main circuit power failure, current sampling Failure, battery management system failure, battery pack undervoltage, battery pack overvoltage, motor overheating, acceleration failure, horn failure, equipment cannot move forward, equipment can only move slowly, the lifting arm cannot rise, the lifting height of the lifting arm is wrong, and the handling Arm down failure.

[0052] Stp3: Establish a fault tree, confirm the basic event, bottom...

Embodiment 2

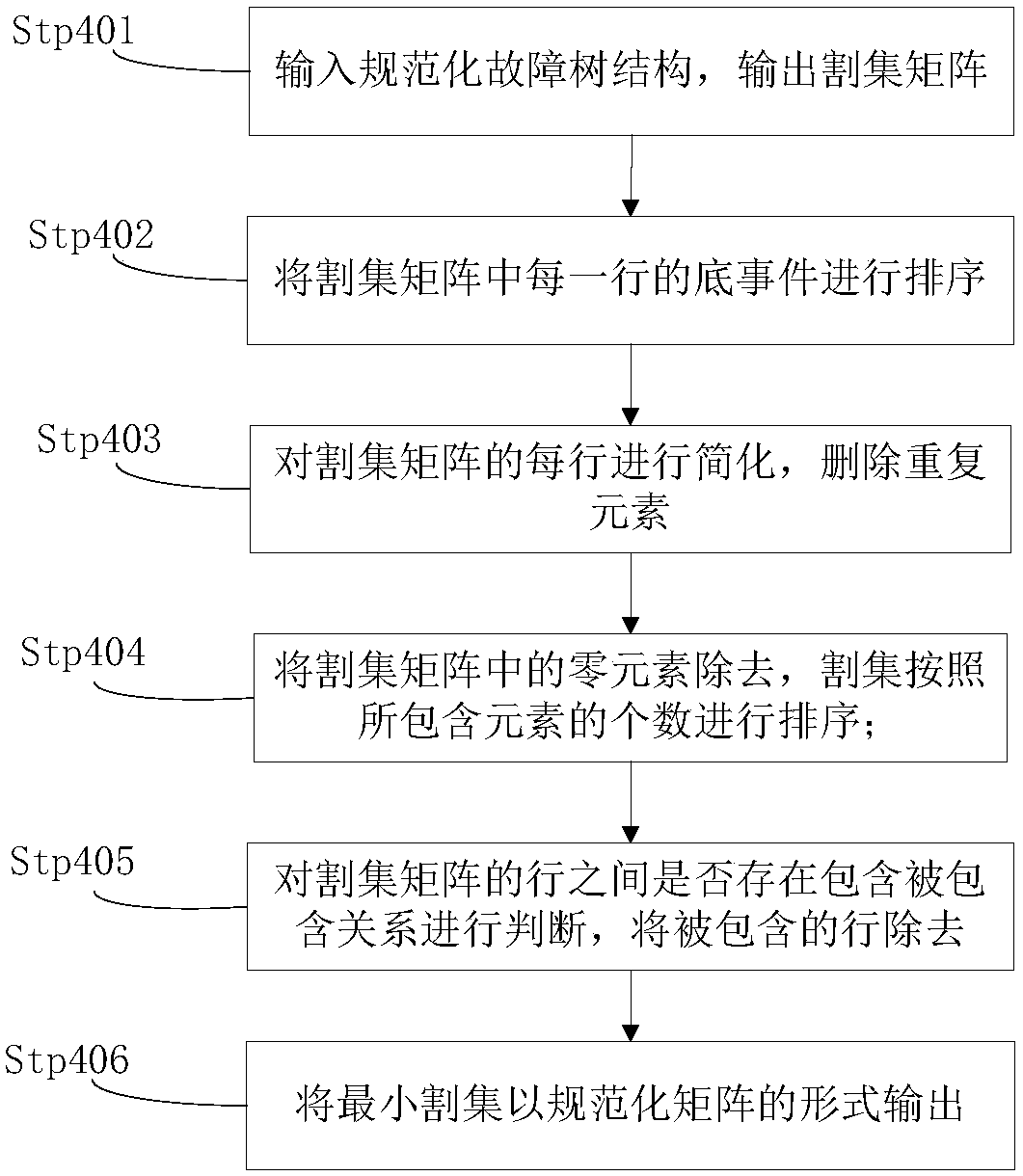

[0059] Such as figure 2 As shown, in this embodiment, on the basis of the foregoing embodiments, the operation of the qualitative analysis module includes the following steps:

[0060] Stp401: Input the normalized fault tree structure, the program uses the descending method to obtain all the cut sets of the fault tree, starting from the top event, search and replace from top to bottom, and increase the number of elements contained in the set when it encounters an AND gate, and when it encounters The OR gate increases the number of cut sets and outputs a cut set matrix. The number of rows of the matrix is the number of cut sets, and each row element is the code corresponding to the bottom event of the cut set.

[0061] Stp402: Use the sorting function to sort the bottom events of each row in the cutset matrix according to the order of codes from small to large.

[0062] Stp403: Using the law of idempotence X i ∩X i =X i Simplify each row of the cut set matrix, compare th...

Embodiment 3

[0068] Such as image 3 As shown, in this embodiment, on the basis of the foregoing embodiments, the operation of the quantitative analysis module includes the following steps:

[0069] Stp501: Disjointize the minimum cut set to obtain a disjointization matrix. When the number of minimum cut sets in the fault tree and the repeated basic events in the minimum cut set are large, directly using the tolerance-exclusion theorem to calculate will greatly increase the amount of calculation, so in order to prevent the combination explosion, it is necessary to complete the corresponding minimum cut set first Computing after disjoint processing operations can effectively improve computing efficiency.

[0070] Stp502: traverse the disjointization matrix to find the disjointization expression of the top event, and calculate the occurrence probability of the top event according to the formula. The calculation formula for the occurrence probability of the top event is:

[0071]

[0072...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com