Expanding rubber pipe and production process thereof

A production process and technology of rubber hoses, applied in the direction of hoses, pipes, tubular objects, etc., can solve the problems of aging and cracking of the outer layer of the expansion rubber tube, affecting the service life of the expansion rubber tube, and poor ductility of the expansion rubber tube, so as to achieve enhanced high temperature resistance. , The effect of improving internal strength and high pressure resistance coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

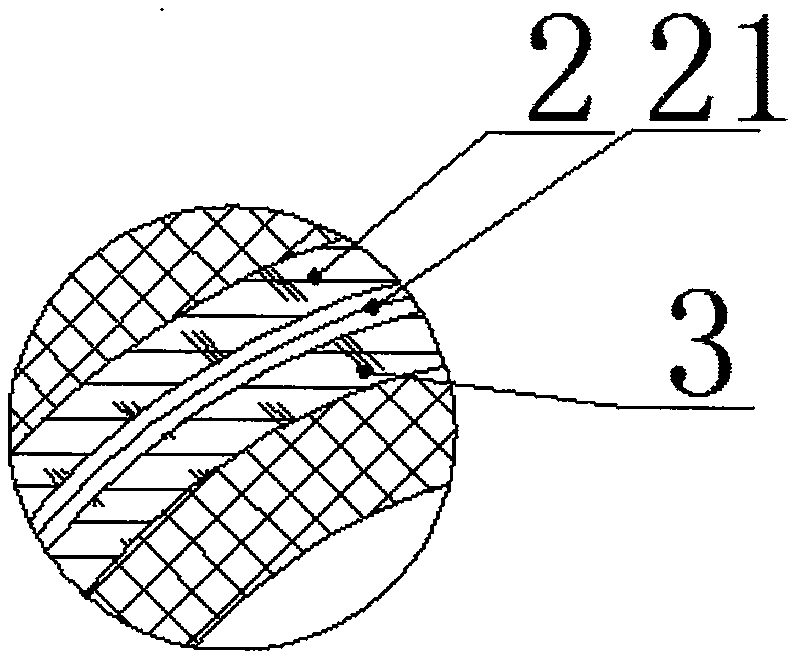

Image

Examples

Embodiment 1

[0027] Take the raw materials for assembly, and assemble with 50 kilograms of ingredients, natural rubber 35%, butadiene rubber 13%, zinc oxide 5%, anti-aging agent A 2%, anti-aging agent D 2%, coumarone 4%, 220 carbon 20% of black, 15% of calcium bicarbonate, 2% of petrolatum, 1% of stearic acid, 0.4% of sulfur, 0.5% of accelerator NOBS, and 0.1% of TMTD.

[0028] The preparation method of described a kind of expansion rubber hose is as follows:

[0029] The production process of the above-mentioned expansion rubber hose is summarized as the following steps, mastication→mixing→extrusion, calendering→forming→vulcanization, and the specific steps are as follows:

[0030] (1) After the above-mentioned components and materials are ready, turn on the hot water adjustment of the chiller, preheat the roller temperature to 75°C, open the silo, add natural rubber, and masticate for 10 minutes;

[0031] (2) Add butadiene rubber, zinc oxide, anti-aging agent A, anti-aging agent D, and ...

Embodiment 2

[0040]Take the above components and proportions, and assemble with 50 kg of ingredients, natural rubber 38%, butadiene rubber 14%, zinc oxide 7%, anti-aging agent A 2%, anti-aging agent D 2%, coumarone 3% , 220 carbon black 15%, calcium bicarbonate 15%, petrolatum 2%, stearic acid 1%, sulfur 0.3%, accelerator NOBS 0.6%, TMTD 0.1%, the proportion of the above components must reach 100%.

[0041] The production technology of described a kind of expansion rubber hose, its preparation method is as follows:

[0042] The production process of the above-mentioned expansion rubber hose is summarized as the following steps, mastication→mixing→extrusion, calendering→forming→vulcanization, and the specific steps are as follows:

[0043] (1) After the above-mentioned components and materials are ready, turn on the hot water adjustment of the chiller, preheat the roller temperature to 80°C, open the silo, add natural rubber, and masticate for 10 minutes;

[0044] (2) Add butadiene rubber,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com