Track traffic overhead station

A rail transit and station technology, applied in the field of rail transit, can solve the problems of large self-weight load, long road occupation period, complicated construction, etc., to reduce environmental impact, reduce road occupation time, and improve construction quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

[0031] This embodiment provides a rail transit elevated station.

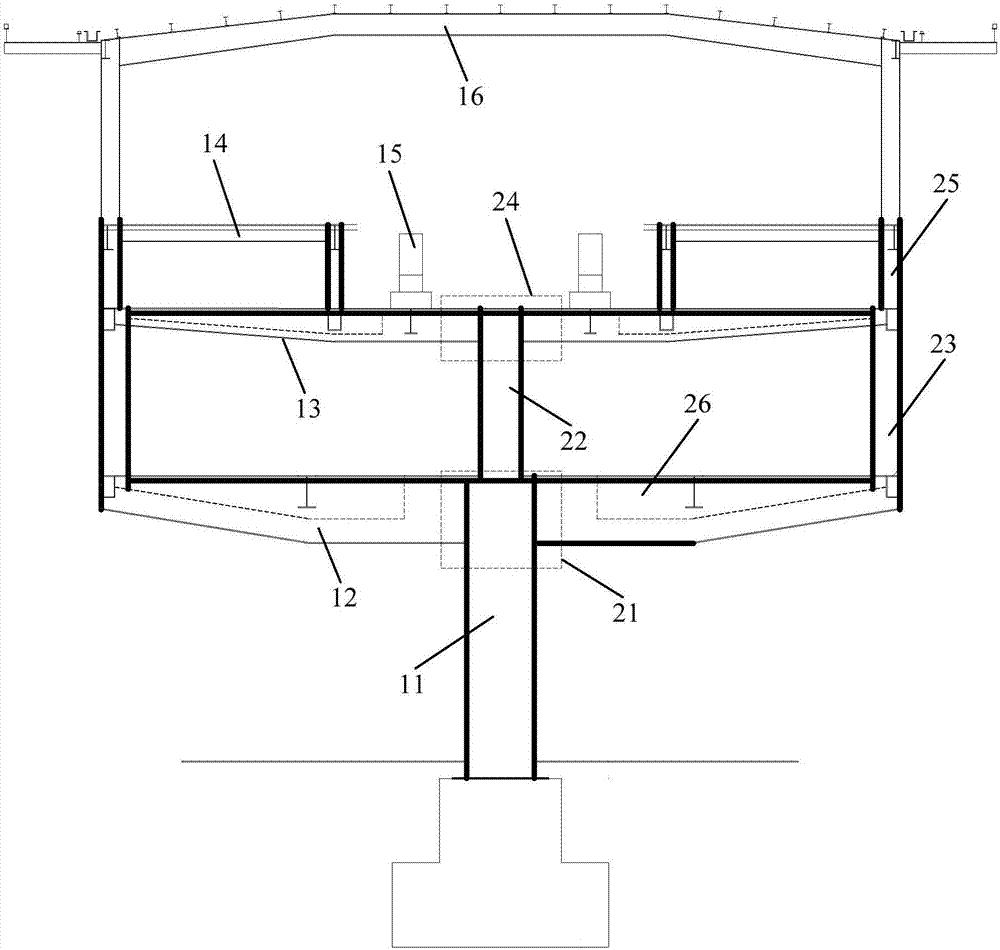

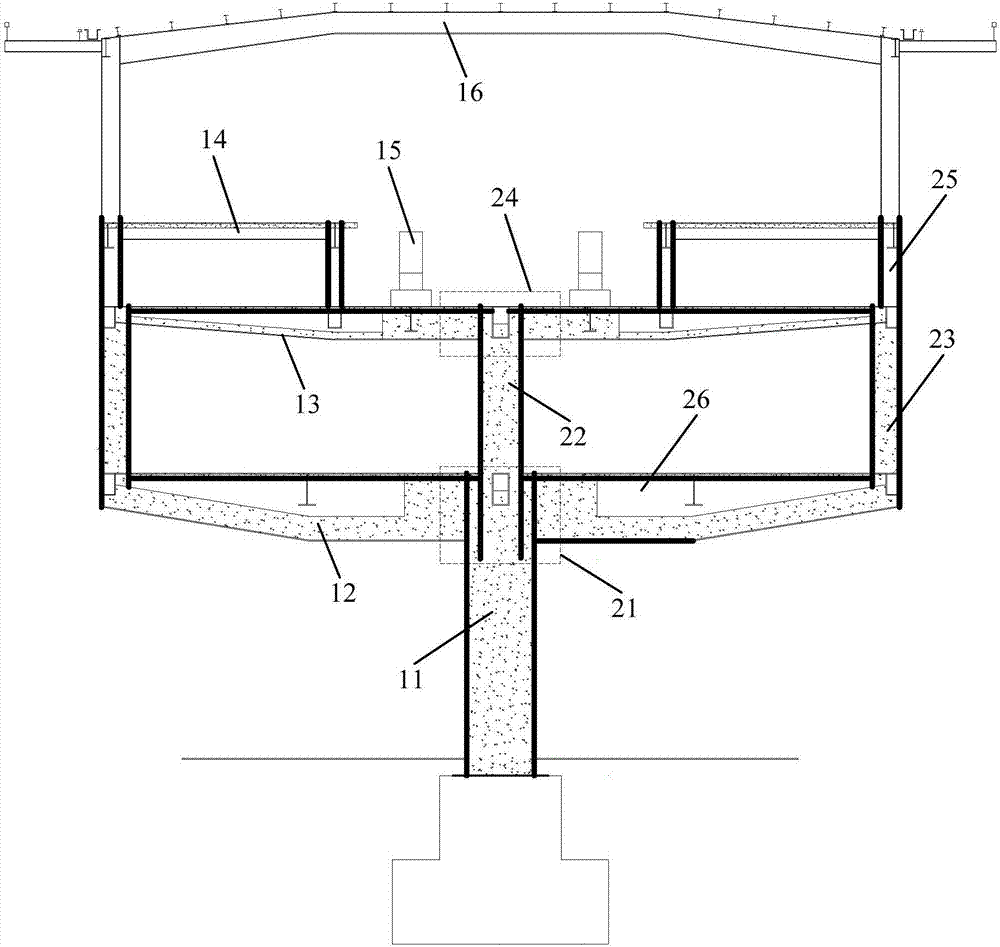

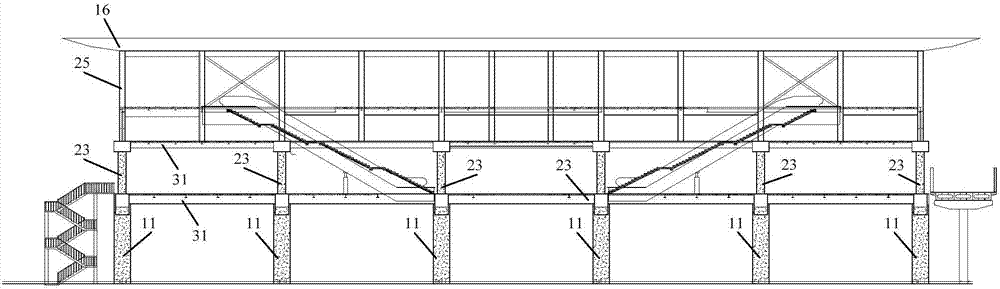

[0032] Figure 1~3 They are respectively a front view, a sectional view and a side view of the rail transit elevated station in the embodiment of the present invention. Such as Figure 1~3 As shown, the rail transit elevated station in the embodiment of the present invention mainly includes: multiple single-column steel-concrete composite frame structures 10;

[0033] Wherein, each single-column steel-concrete composite frame structure includes: pier column 11, first steel-concrete composite beam 12, second steel-concrete composite beam 13, platform structure 14, track beam 15 and roof canopy 16;

[0034] The top of the pier column 11 is equipped with a first combined beam-column node...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com