Pressure quenching and tempering integrated machine tool for thin-wall annular parts

A ring-shaped part, quenching and tempering technology, which is applied in the field of thin-walled ring-shaped parts press-quenching-tempering integrated machine tools, can solve the problem of reducing the holding force of thin-walled ring parts to the mandrel, high maintenance cost of the mandrel, and technical process. Lengthening and other issues can be achieved to save storage and transportation costs, reduce maintenance costs, and increase safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

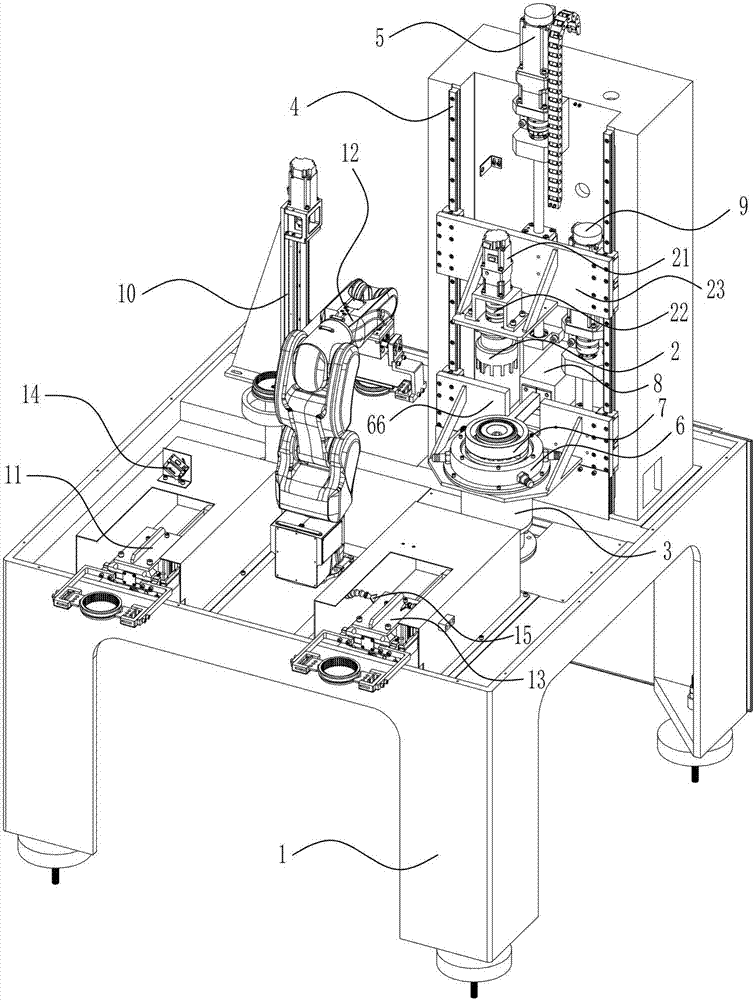

[0034] An integrated press quenching and tempering machine tool for thin-walled ring parts, such as Figure 1-Figure 5 As shown, it includes frame 1, upper mold 2, upper mold slider 23, lower mold 3, guide rail 4, upper mold lifting assembly 5, liquid spray ring 6, liquid spray ring slider 66, tempering heating sensor 7 , tempering transformer assembly 8, liquid spray ring lifting assembly 9, quenching heating assembly 10, upper mold rotating drive assembly and lower mold rotating driving assembly; lower mold 3, guide rail 4, upper mold lifting assembly 5 and quenching heating assembly 10 Installed on the frame 1 through bolt connection; the quenching heating assembly 10 includes a quenching heating sensor lifting assembly 101, a quenching transformer assembly 102, a quenching heating inductor 103, a quenching heating tray 104, a motor III 105 and a coupling II 106, and the quenching The heating inductor lifting assembly 101 is installed on the frame 1 through bolt connection,...

Embodiment 2

[0038] An integrated press quenching and tempering machine tool for thin-walled ring parts, such as Figure 1-Figure 6 As shown, it includes frame 1, upper mold 2, upper mold slider 23, lower mold 3, guide rail 4, upper mold lifting assembly 5, liquid spray ring 6, liquid spray ring slider 66, tempering heating sensor 7 , Tempering and variable pressure assembly 8, liquid spray ring lifting assembly 9, quenching heating assembly 10, feeding manipulator 11, six-axis manipulator 12, unloading manipulator 13, laser sensor 14, high-pressure air gun 15, machine tool shell 16, conveyor 17. Liquid storage cooling cycle assembly 18 and control cabinet assembly 19; lower mold 3, guide rail 4, upper mold lifting assembly 5, quenching heating assembly 10, feeding manipulator 11, six-axis manipulator 12, unloading manipulator 13 and machine tool shell 16 are installed on the frame 1 through bolt connection, the upper mold slider 23 is set on the guide rail 4, the upper mold lifting assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com