Polypropylene pipe used for underground coal mine

A polypropylene pipe and polypropylene technology, which is applied in the field of polypropylene pipes used in coal mines, can solve the problems of low heat resistance, high price, and easy delamination, and achieve improved antistatic properties, improved mechanical properties, and good antistatic properties sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

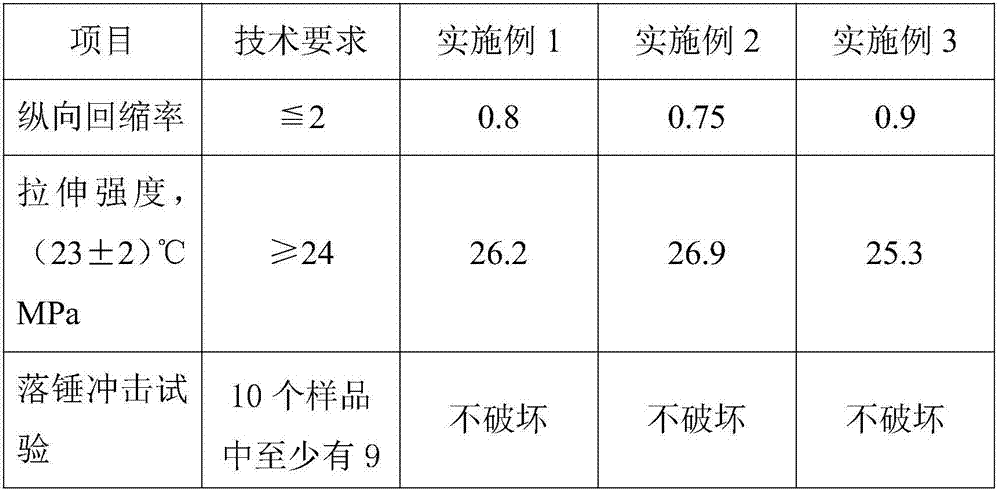

Examples

Embodiment 1

[0014] A polypropylene pipe for underground coal mines, calculated in parts by weight, comprising the following raw materials:

[0015] 95 parts of polypropylene, 2 parts of barium sulfate whisker, 2 parts of aluminum hydroxide, 7 parts of magnesium hydroxide, 1 part of zinc borate, 12 parts of antistatic agent, 6 parts of polypropylene grafted acrylic acid, methacrylate-butylene 10 parts of ethylene-styrene copolymer, 0.8 parts of antioxidant CA and 0.8 parts of dispersant.

[0016] The antistatic agent is prepared by the following method: disperse conductive carbon black and acetylene carbon black in an appropriate amount of water to form a dispersion liquid, add glass fiber and soak for 10 hours, take it out and bake to obtain the antistatic agent.

Embodiment 2

[0018] A polypropylene pipe for underground coal mines, calculated in parts by weight, comprising the following raw materials:

[0019] 100 parts of polypropylene, 1 part of barium sulfate whisker, 8 parts of aluminum hydroxide, 3 parts of magnesium hydroxide and 1 part of zinc borate, 10 parts of antistatic agent, 8 parts of polypropylene grafted maleic anhydride, methacrylate- 12 parts of butadiene-styrene copolymer, 1.2 parts of antioxidant CA and 1.2 parts of dispersant.

[0020] The antistatic agent is prepared by the following method: disperse conductive carbon black and acetylene carbon black in an appropriate amount of water to form a dispersion liquid, add glass fiber and soak for 12 hours, take it out and bake to obtain the antistatic agent.

Embodiment 3

[0022] A polypropylene pipe for underground coal mines, calculated in parts by weight, comprising the following raw materials:

[0023] 90 parts of polypropylene, 3 parts of barium sulfate whiskers, 2 parts of aluminum hydroxide, 0.8 parts of magnesium hydroxide and 0.2 parts of zinc borate, 16 parts of antistatic agent, 4 parts of ethylene-vinyl acetate copolymer grafted maleic anhydride, 6 parts of acrylate-butadiene-styrene copolymer, 0.6 part of antioxidant CA and 0.6 part of dispersant.

[0024] The antistatic agent is prepared by the following method: disperse conductive carbon black and acetylene carbon black in an appropriate amount of water to form a dispersion liquid, add glass fiber and soak for 12 hours, take it out and bake to obtain the antistatic agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com