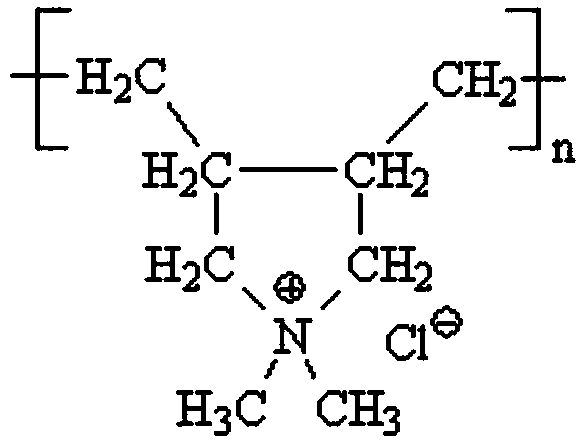

Preparation method of flocculant polydimethyldiallyl ammonium chloride for sewage treatment

A technology of polydimethyldiallyl ammonium chloride and dimethyldiallyl ammonium chloride, which is applied in the direction of flocculation/sedimentation water/sewage treatment, mining wastewater treatment, etc., and can solve the problem of difficult control of relative molecular quality , Polymer viscosity is high, on-site filling difficulties and other problems, to achieve the effect of easy control of reaction temperature, low product viscosity, and convenient filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

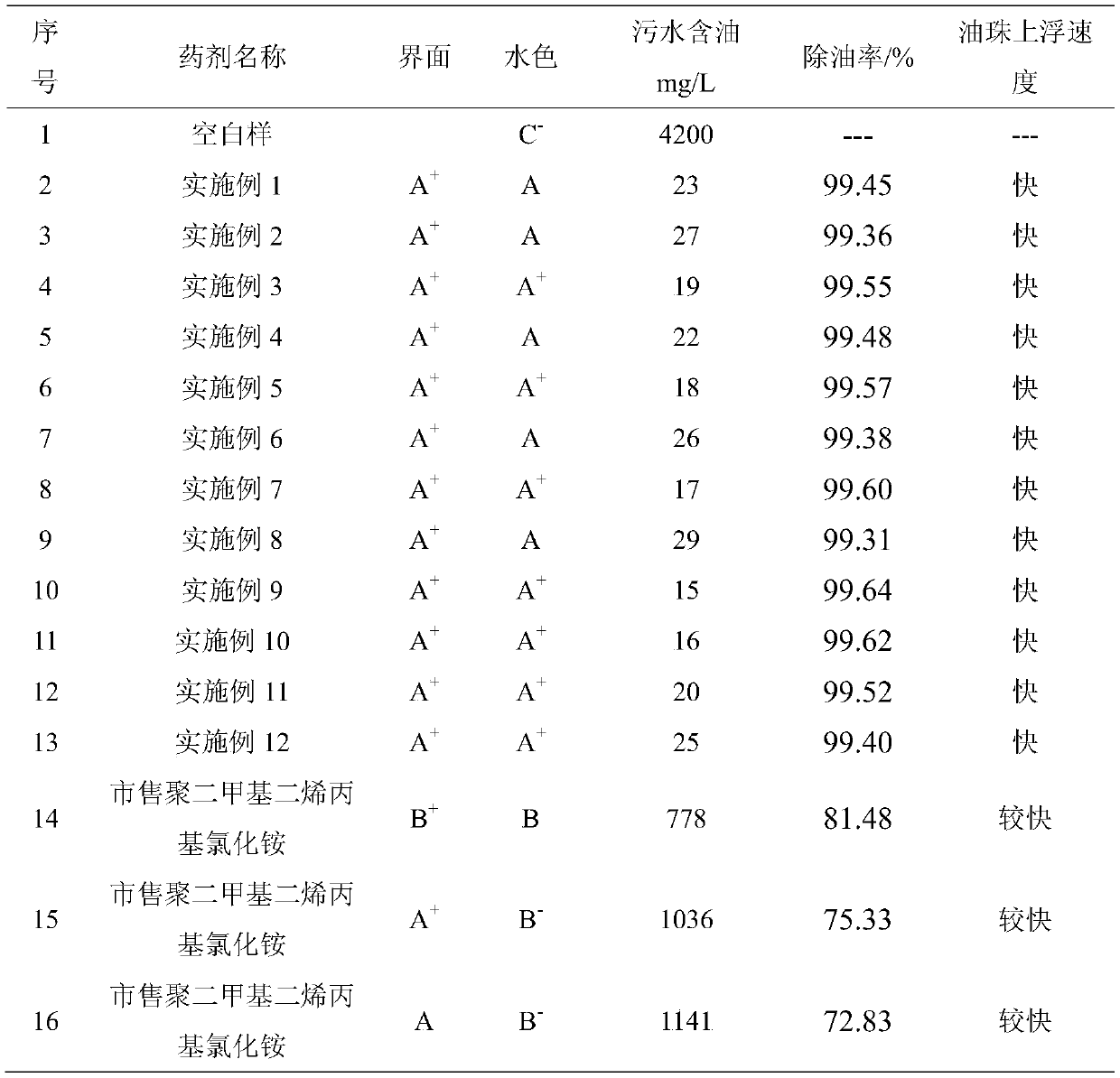

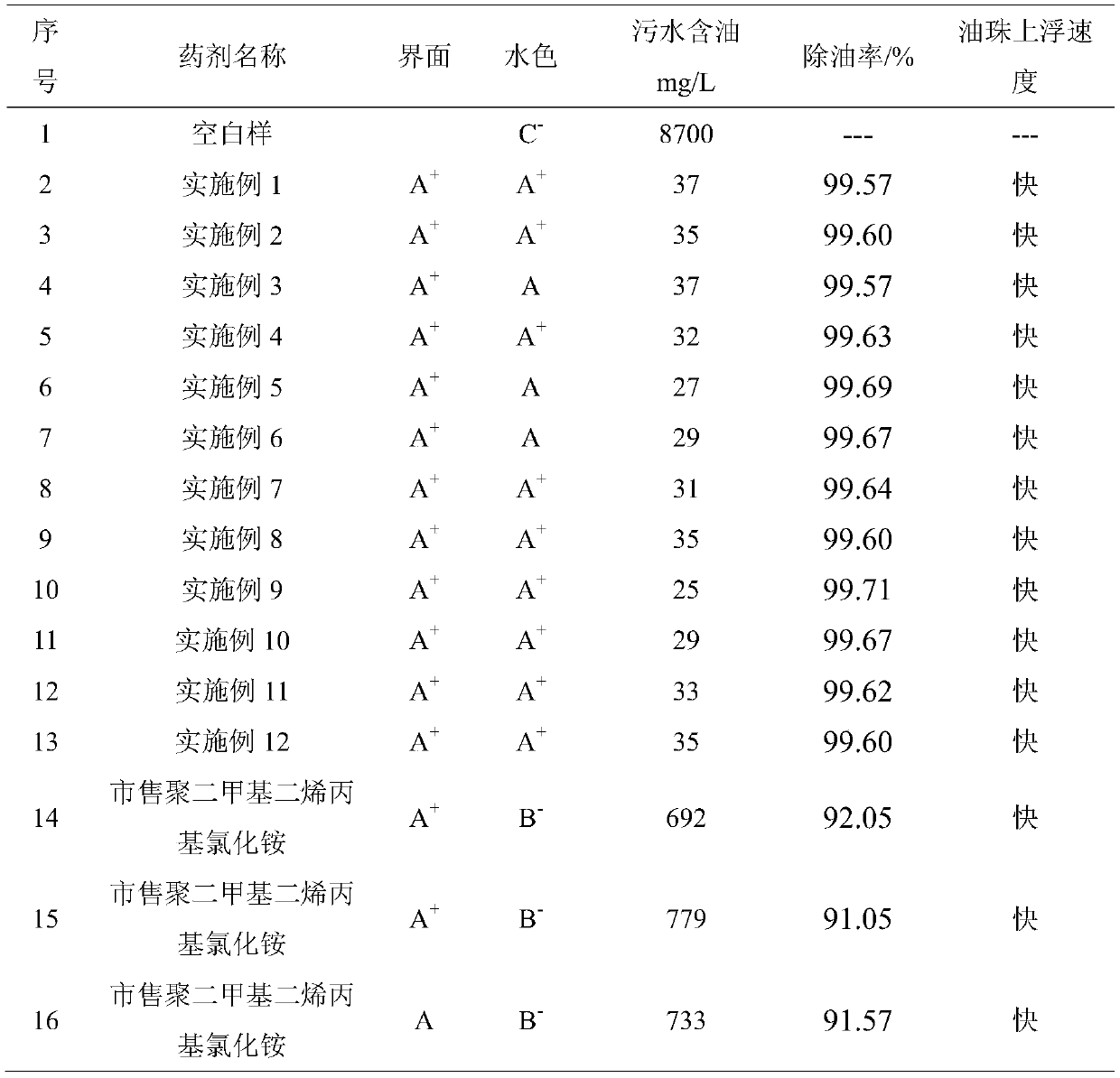

Examples

Embodiment 1

[0037] The preparation method of the first kind of sewage treatment flocculant polydimethyldiallyl ammonium chloride comprises the steps:

[0038] (1) Take 167g of concentration and put it into the reaction vessel, add 0.1g of azobisisobutylamidine hydrochloride, 0.08g of disodium edetate, 10g of dimethyldiallyl ammonium chloride aqueous solution Ethylene glycol, stir evenly, pass into nitrogen to remove the air in the reaction vessel;

[0039] (2) The reaction solution obtained in step (1) was heated up to 40° C. under stirring, and the polymerization reaction was carried out for 3 hours;

[0040] (3) Heat the reaction solution obtained in step (2) to 65°C, add 500g of deionized water, control the temperature at 65°C to 85°C, and react for 1.5h;

[0041] (4) Under the protection of nitrogen, adjust the temperature at 50° C., and heat-preserve for 3 hours to obtain the polydimethyldiallylammonium chloride product.

Embodiment 2

[0043] The preparation method of the first kind of sewage treatment flocculant polydimethyldiallyl ammonium chloride comprises the steps:

[0044] (1) get 143g concentration and be that 70wt% dimethyl diallyl ammonium chloride aqueous solution is put into reaction container, add 2g ammonium persulfate, 0.15g tetrasodium edetate, 65g ethylene glycol, stir, Feed nitrogen to remove the air in the reaction vessel;

[0045] (2) The reaction solution obtained in step (1) was heated up to 60° C. under stirring, and the polymerization reaction was carried out for 1 hour;

[0046] (3) Heat the reaction solution obtained in step (2) to 85°C, add a mixed solution of 0.4g of ammonium persulfate and 10g of deionized water, control the temperature at 85°C to 110°C, and react for 2.5h;

[0047] (4) Under the protection of nitrogen, adjust the temperature at 80° C., and heat-preserve for 7 hours to obtain the polydimethyldiallylammonium chloride product.

Embodiment 3

[0049] The preparation method of the first kind of sewage treatment flocculant polydimethyldiallyl ammonium chloride comprises the steps:

[0050] (1) get 154g concentration and be that 65wt% dimethyl diallyl ammonium chloride aqueous solution is put into reaction vessel, add 1g sodium persulfate, 0.1g sodium ethylenediamine tetramethylene phosphate, 35g ethylene glycol, stir well , feed nitrogen to remove the air in the reaction vessel;

[0051] (2) The reaction solution obtained in step (1) was heated up to 50° C. under stirring, and the polymerization reaction was carried out for 2 hours;

[0052] (3) Heat the reaction solution obtained in step (2) to 75°C, add a mixed aqueous solution of 0.01g of sodium persulfate and 130g of deionized water, control the temperature at 75°C to 95°C, and react for 2 hours;

[0053] (4) Under the protection of nitrogen, adjust the temperature at 60° C., and heat-preserve for 4 hours to obtain the polydimethyldiallylammonium chloride product. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com