A method for preparing polyacrylate by single electron transfer-living radical polymerization

A polyacrylate and single-electron transfer technology, which is applied in the field of single-electron transfer-living free radical polymerization to prepare polyacrylate, can solve the problems of difficult access to free radical reagents, large amount of catalysts, troublesome post-processing, etc., and achieve simple addition of raw materials , Omit deoxidation steps, simplify the effect of the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

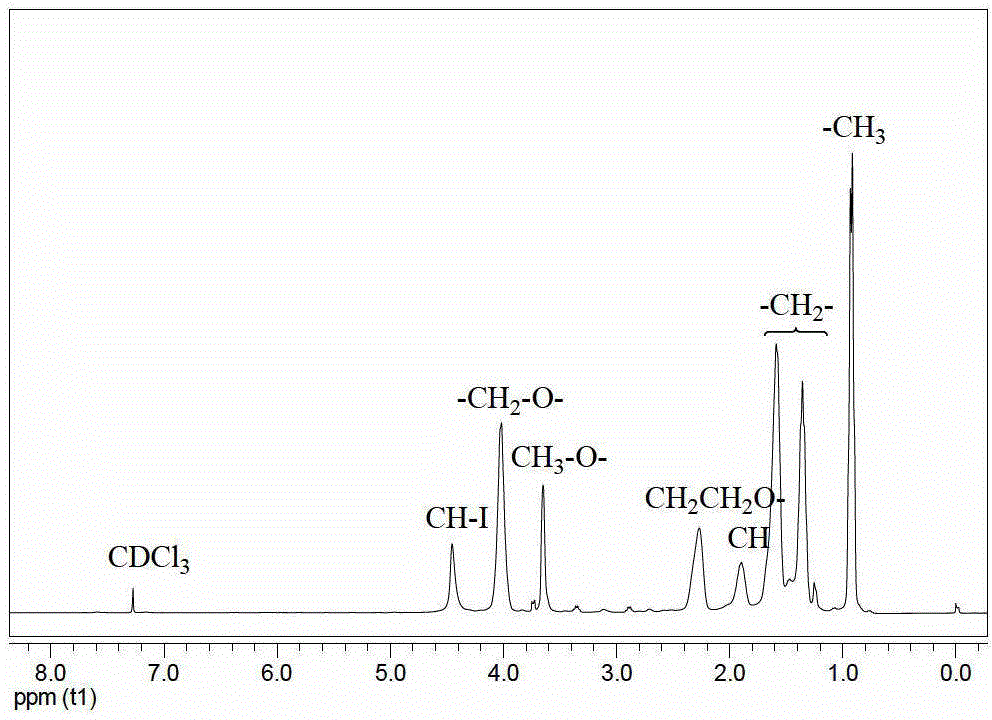

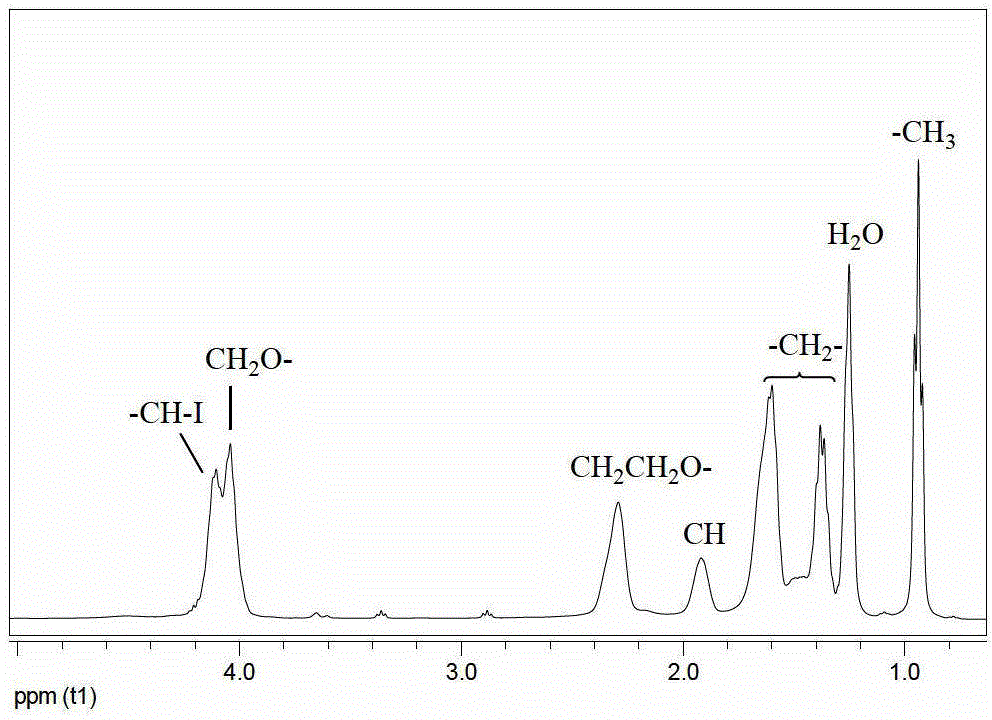

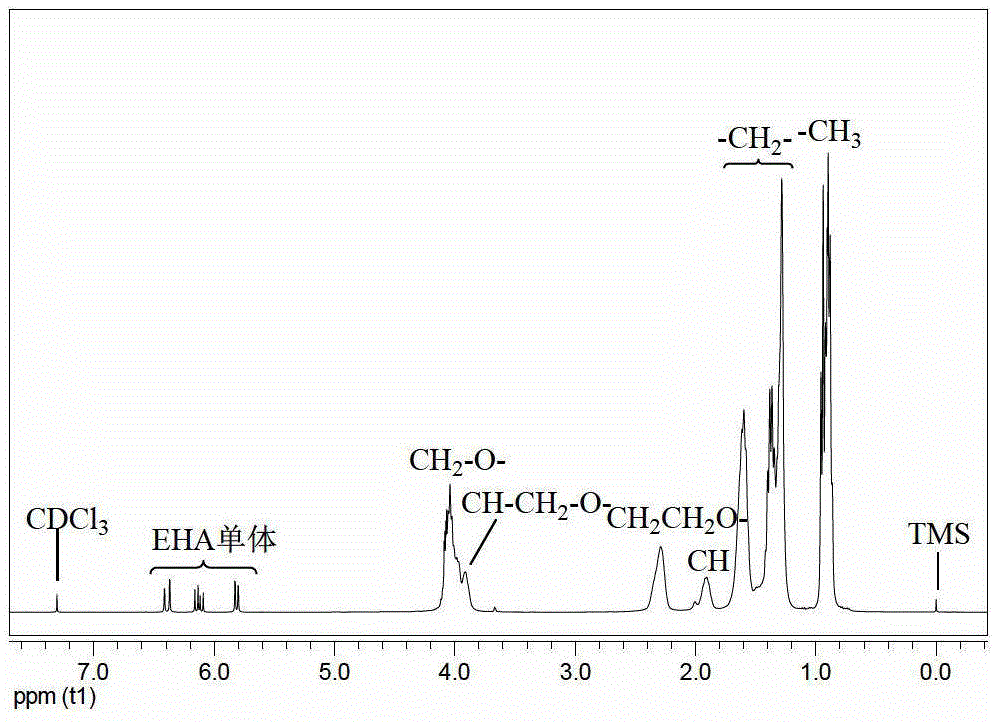

Image

Examples

Embodiment 1

[0035] Put the reaction device in a constant temperature water bath preheated to 40°C, add 180ml deionized water, 5.02g polyvinyl alcohol (PVA) aqueous solution (mass concentration = 4.85%) and 3.04g hydroxypropyl methylcellulose (HPMC) aqueous solution (mass concentration = 3.95%), stirred for 20 minutes, and then added 0.20 g of sodium bicarbonate (NaHCO 3 ), 1.17g sodium dithionite (Na 2 S 2 o 4 ), 0.66g iodoform (CHI 3 ) and 54g of n-butyl acrylate (BA), stop the reaction after 1h, remove the device, pour off the water in the system, put the product in a pre-dried and weighed beaker, and put it in a vacuum oven at 40°C and 0.09Mpa After vacuum drying, the desired product was obtained after complete drying. The monomer conversion rate α=85.23% was measured by weighing method, and M was measured by gel permeation chromatography (GPC). n =20252, M w / M n =1.78.

Embodiment 2

[0037] Same as Example 1, the reaction time was extended to 3h. Monomer conversion rate α=90.60%, M measured by GPC n =47256, M w / M n =1.91.

Embodiment 3

[0039] Same as Example 1, the reaction time was extended to 4h. Monomer conversion rate α=94.10%, M measured by GPC n =50319, M w / M n =2.35.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com